Corrugated steel pressure pipeline welding and sealing method

A technology for welding, sealing and pressure piping, which is applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., and can solve problems such as poor sealing effect of corrugated steel pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

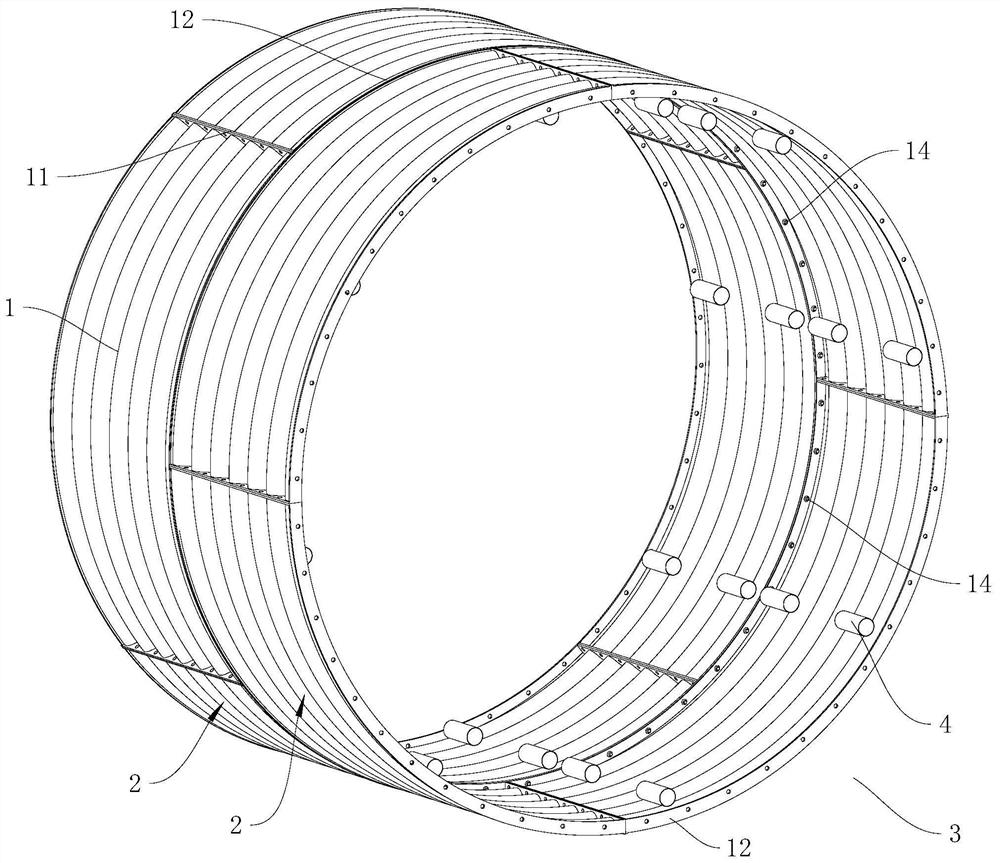

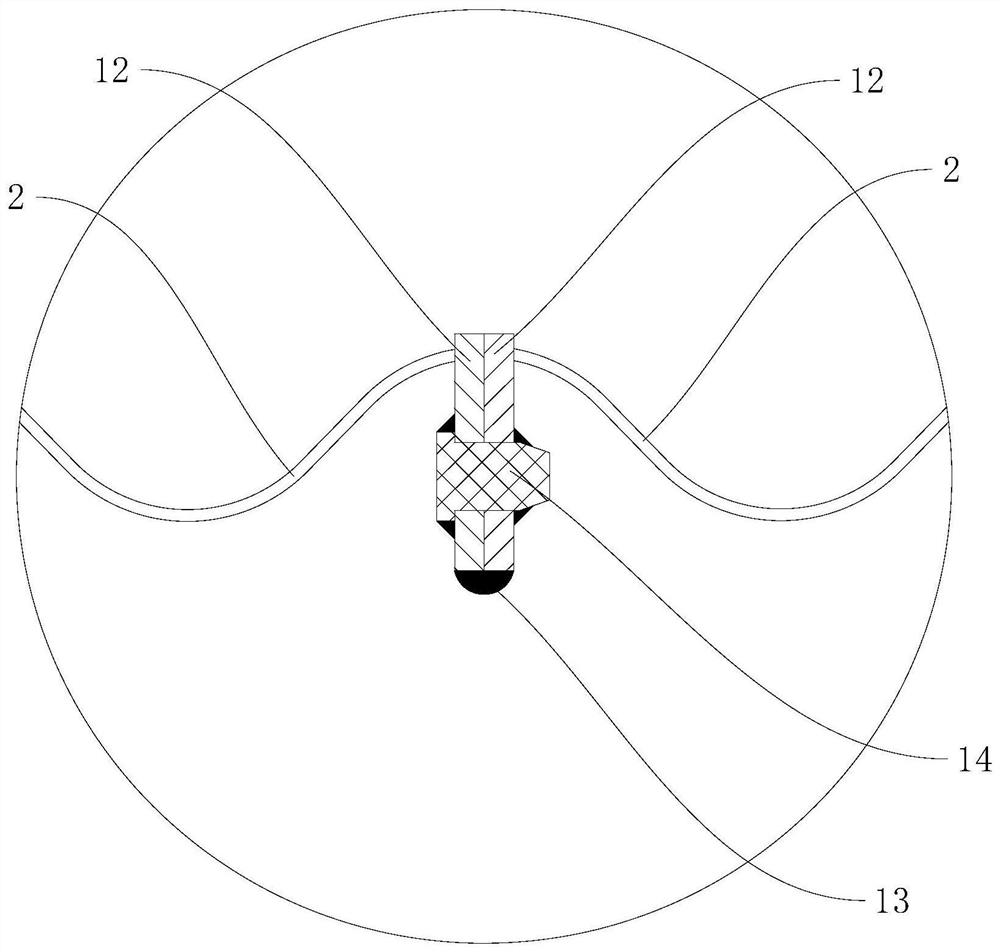

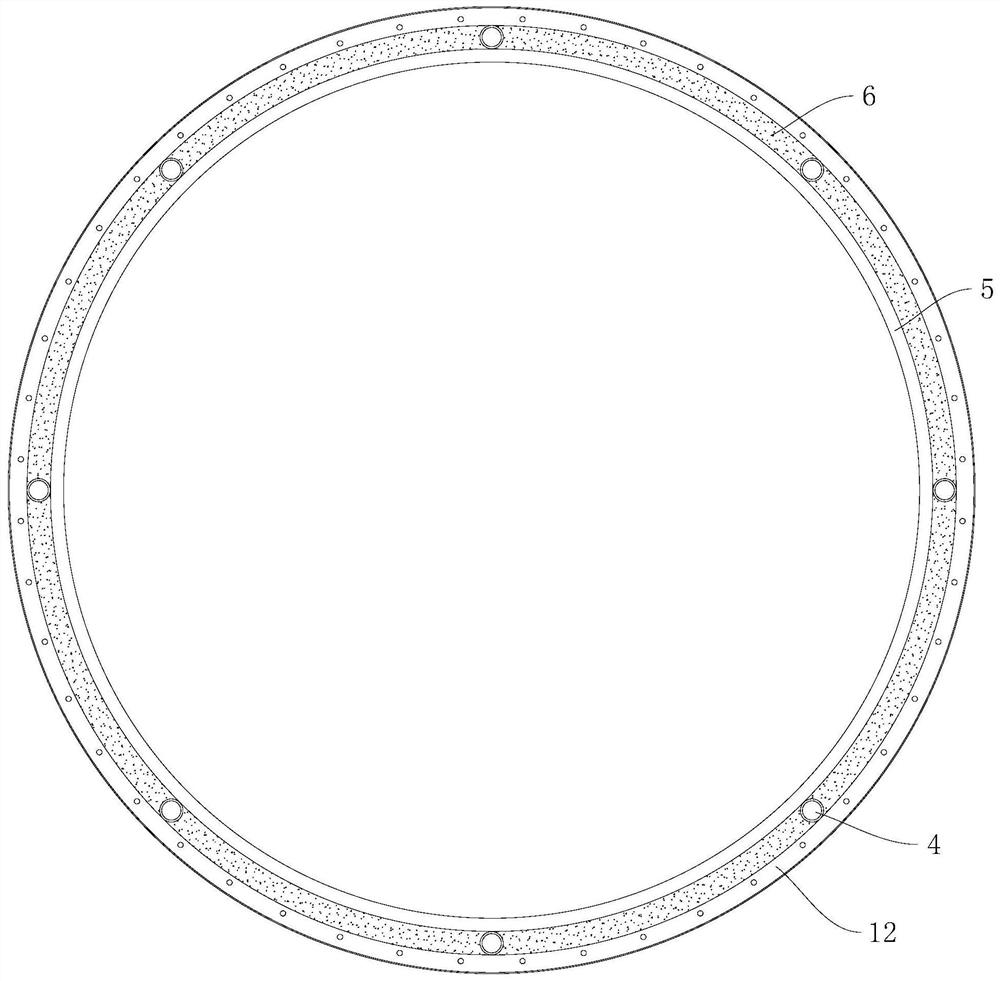

[0024] see Figure 1 to Figure 3 , the corrugated steel pressure pipe welding sealing method 13 provided by the present invention will now be described. A method for welding and sealing corrugated steel pressure pipes, comprising:

[0025] A plurality of connecting plates 1 are used to splice into a ring structure 2, the first flanges 11 at the ends of two adjacent connecting plates 1 are butted, and bolts are used to pass through the screw holes on the first flanges 11 for temporary fixation Connect two adjacent connection plates 1;

[0026] Use the conical pin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap