Oil smoke separator

A technology of oil fume separator and condensation sheet, which is applied in the field of life and can solve problems such as high noise and small exhaust air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

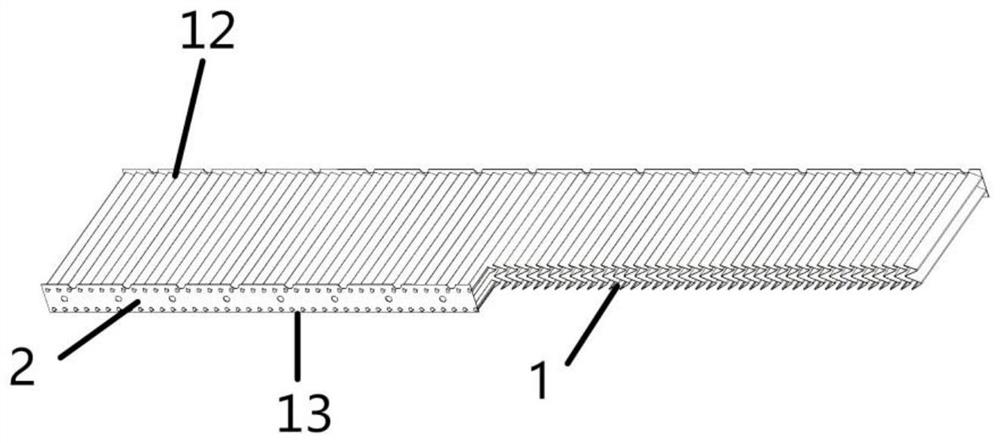

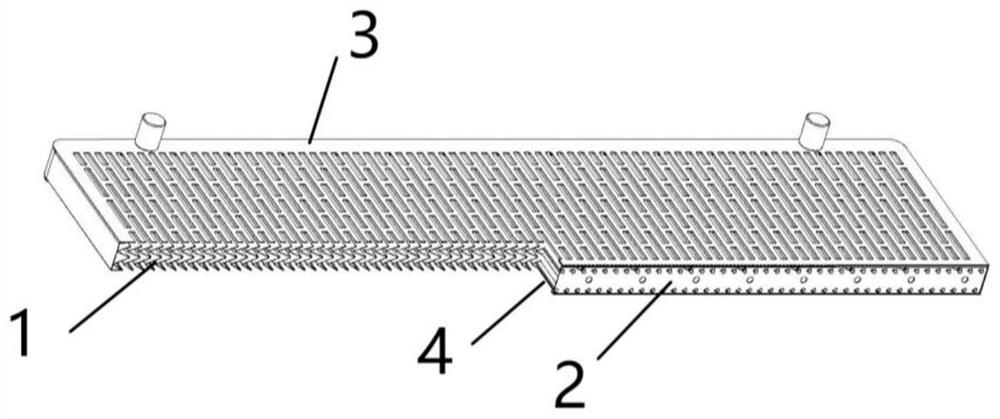

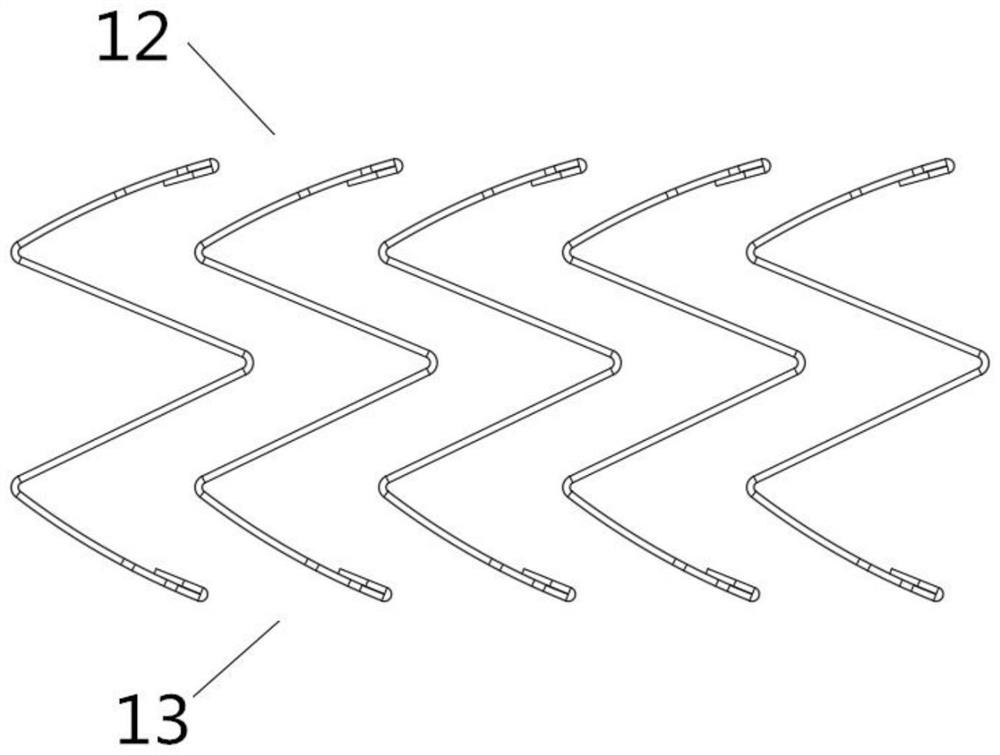

[0032] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] At present, the oil fume separation and filtering devices on the market generally adopt a sheet metal filter structure with single or double openings that are staggered and overlapped with each other. There is still a lot of grease on the inner wall of the body, which is purely an electrical safety requirement setting. One is the oil fume separation structure using double-layer or three-layer die-casting aluminum. Considering the die-casting aluminum process and strength, it basically adopts 8 to 12 long strip holes in the shape of an air inlet channel and is composed of two oil fume separation nets, and there are fewer long strips. The hole structure makes the air intake area of the oil fume separation net seriously insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com