Natural wind simulation device for meat air-drying

A simulation device and natural wind technology, applied in the field of meat air-drying, can solve the problems of high humidity of materials, poor taste of air-dried materials, and inability to simulate natural wind well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

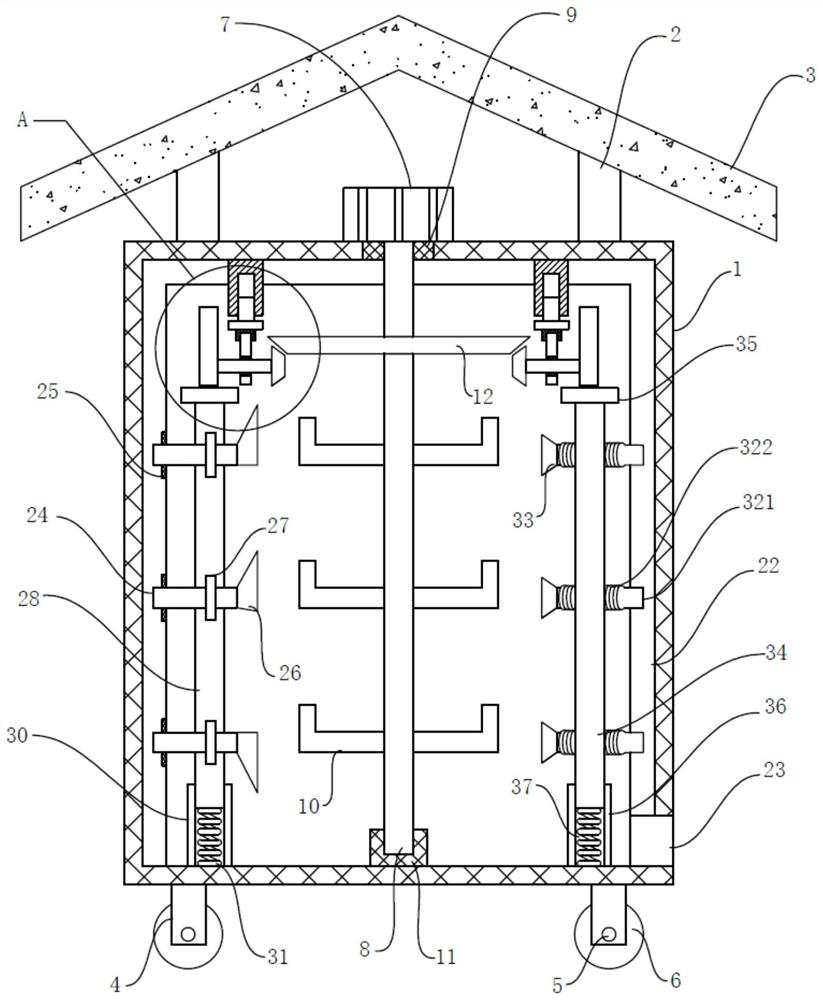

[0034] Embodiment 1: When the temperature and wind force in the external environment reach the appropriate conditions, the meat to be air-dried can be directly hung on the hook 10, then the door is closed, and the grid box 1 is moved to a suitable position by the universal wheel 6. place to dry naturally.

Embodiment 2

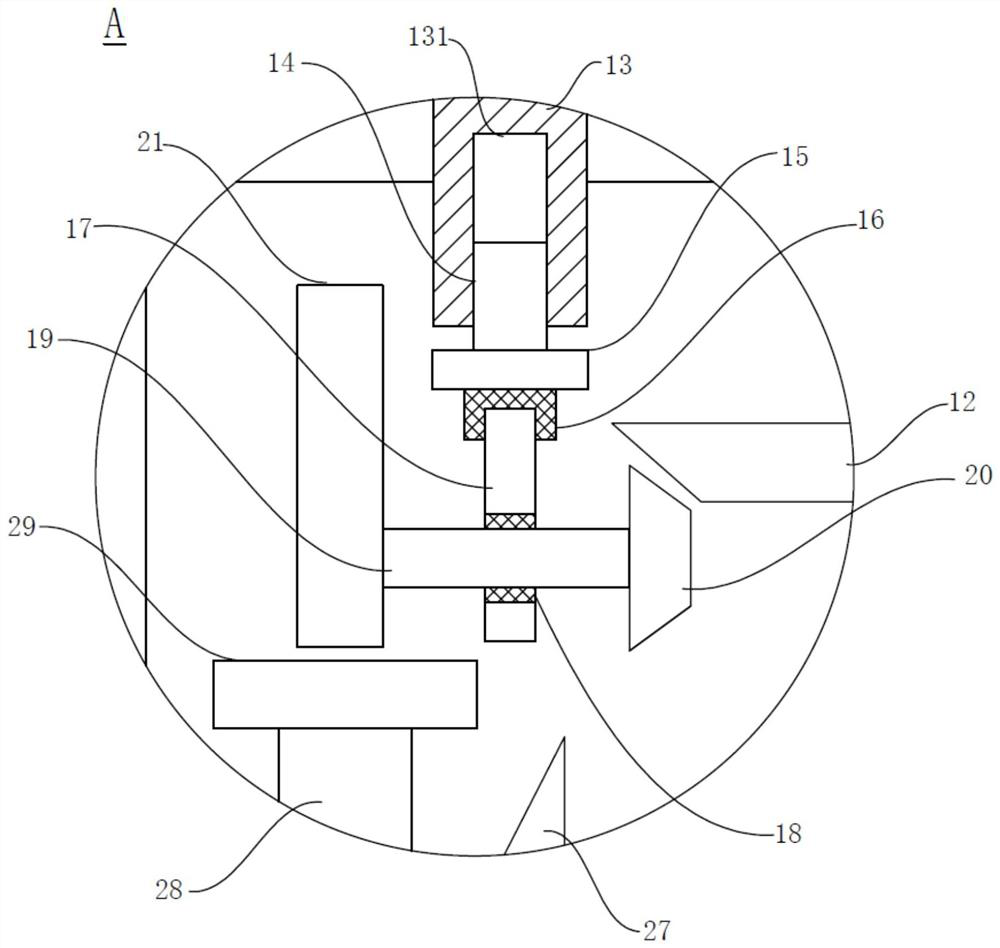

[0035] Embodiment 2: When the temperature and wind force in the external environment do not reach suitable conditions, the meat to be air-dried can be hung on the hook 10 first, and then the fixed ring 15 on the left side is manually rotated so that the threaded rod 14 is on the fixed block 13 rotates in the thread groove 131. During the rotation, the threaded rod 14 will drive the bearing seat 2 16 to rotate, while the extension rod 17 will remain relatively stable, that is, the extension rod 17 will not rotate with the bearing seat 2 16. After the rotation, The height of the extension rod 17 has also been adjusted until the passive bevel gear 20 on the left side meshes with the driving bevel gear 12, and then according to the above operation, the passive bevel gear 20 on the right side is adjusted to the position where it does not mesh with the driving bevel gear 12. Position, close the box door, move the grid box 1 to a suitable place through the universal wheel 6, start the...

Embodiment 3

[0036] Embodiment 3: When the temperature and wind force in the external environment do not reach suitable conditions, the meat to be air-dried can be hung on the hook 10 first, and then the fixed ring 15 on the right side is manually rotated so that the threaded rod 14 is on the fixed block 13 rotates in the thread groove 131. During the rotation, the threaded rod 14 will drive the bearing seat 2 16 to rotate, while the extension rod 17 will remain relatively stable. After the rotation, the height of the extension rod 17 has also been adjusted until the right side The passive bevel gear 20 is meshed with the active bevel gear 12, and then according to the above operation, the passive bevel gear 20 on the left side is adjusted to a position that does not mesh with the active bevel gear 12, and then the door is closed, and the net is moved by the universal wheel 6. The grid box 1 moves to a suitable place and starts the rotating motor 7. On the one hand, the rotating motor 7 dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com