Method for calculating bonding area of automobile brake pad lining

A technology of bonding area and brake pads, which is applied in the field of auto parts and can solve problems such as parameters without bonding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

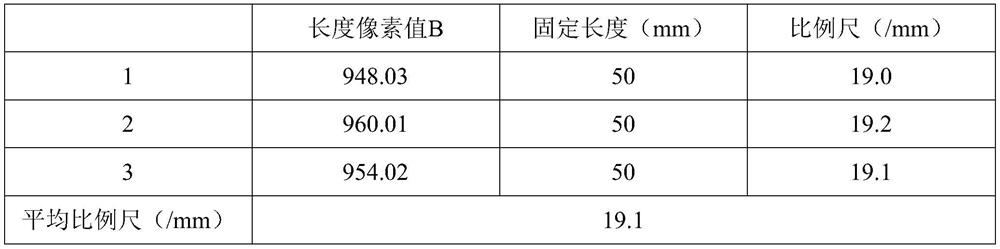

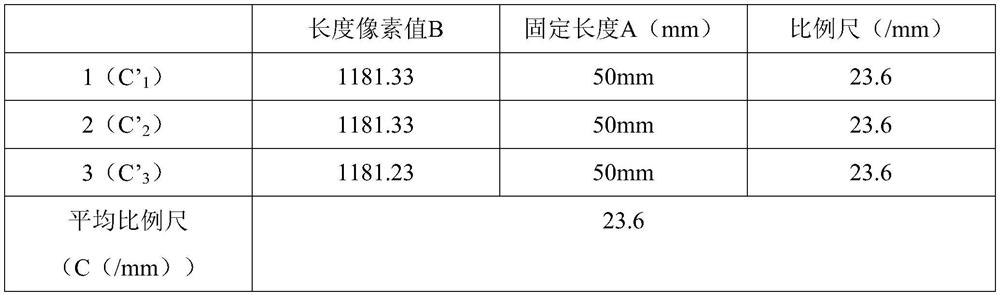

Embodiment 1

[0043] Process the picture through photoshop, check the outline of the brake pad lining, and obtain the pixel value B of the area as 2313589, and calculate the bonded area of the brake pad lining S=2313589÷23.6 2 ≈4154mm 2 .

Embodiment 2

[0045] Process the picture through photoshop, check the outline of the brake pad lining, and obtain the pixel value B of the area as 1329099, and calculate the bonded area of the brake pad lining S=1329099÷23.6 2 ≈2386mm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com