Winding device for producing inductance coil for power adapter and using method thereof

A technology for power adapters and inductance coils, which is applied in coil manufacturing, inductance/transformer/magnet manufacturing, circuits, etc. It can solve problems affecting the quality of winding, poor versatility, and cumbersome fixed inductance, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

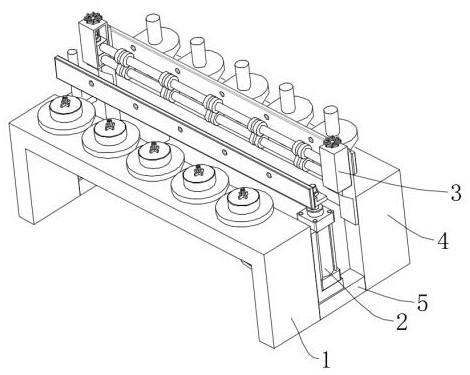

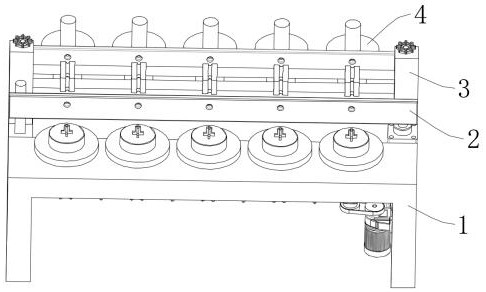

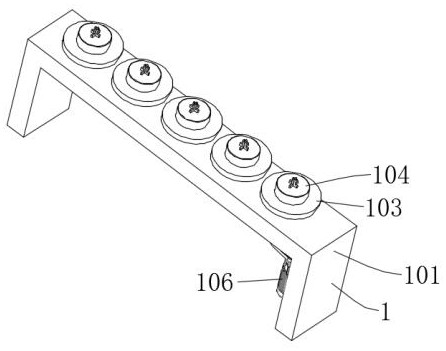

[0040] Such as Figure 1-8 As shown in the figure, a winding device produced by an inductance coil for a power adapter includes a winding mechanism 1, a wiring mechanism 2, a tensioning mechanism 3, a wire releasing mechanism 4, and a connecting column 5, and a wiring mechanism is fixed behind the winding mechanism 1 2. A pay-off mechanism 4 is arranged behind the wiring mechanism 2, and a tension mechanism 3 is fixed in front of the pay-off mechanism 4. The bottom between the winding mechanism 1 and the pay-off mechanism 4 is connected with a connecting column 5 by bolts. The winding mechanism 1 includes Front frame 101, drive shaft 102, rotating disk 103, support chuck 104, transmission gear 105, driving assembly one 106, several rotating disks 103 are arranged at equal intervals on the top of front frame 101, and the center of rotating disk 103 tops is connected by bolts There is a support chuck 104, the bottom of the rotating disk 103 is connected with a drive shaft 102 th...

Embodiment 2

[0047] Such as Figure 9 As shown, the difference between Embodiment 2 and Embodiment 1 is that the drive assembly 3 307 includes a transmission screw 30701 and a rotating head 30702, the lower end of the transmission screw 30701 is rotatably connected to the top of the slider 304, and the upper end of the transmission screw 30701 passes through the bottom of the slide rail 302 The top plate extends to the top of the slide rail 302, and is welded with a rotating head 30702. The transmission screw 30701 is threadedly connected with the top plate of the slide rail 302. In this way, the rotation head 30702 can drive the transmission screw 30701 to rotate, thereby making the transmission screw 30701 rises, the transmission screw 30701 drives the slider 304 to rise, and the slider 304 drives the connecting rod 305 and the tensioning pulley 306 on the connecting rod 305 to rise, thereby making the distance between the two tensioning pulleys 306 larger, which facilitates the steel wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com