High-voltage vacuum circuit breaker

A vacuum circuit breaker and high-voltage technology, which is applied in high-voltage air circuit breakers, high-voltage/high-current switches, circuits, etc., can solve problems such as broken copper sheets, short external insulation distance, and difficult replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

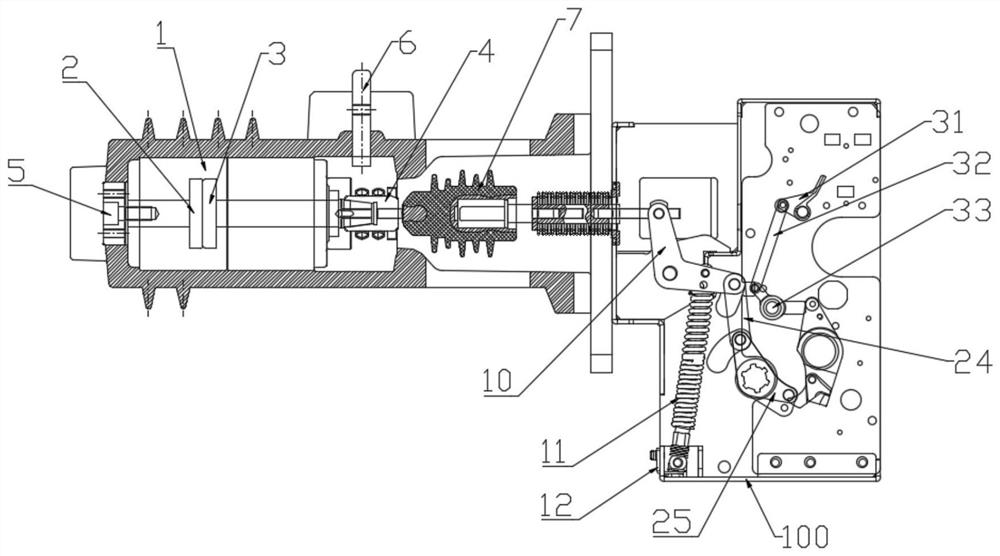

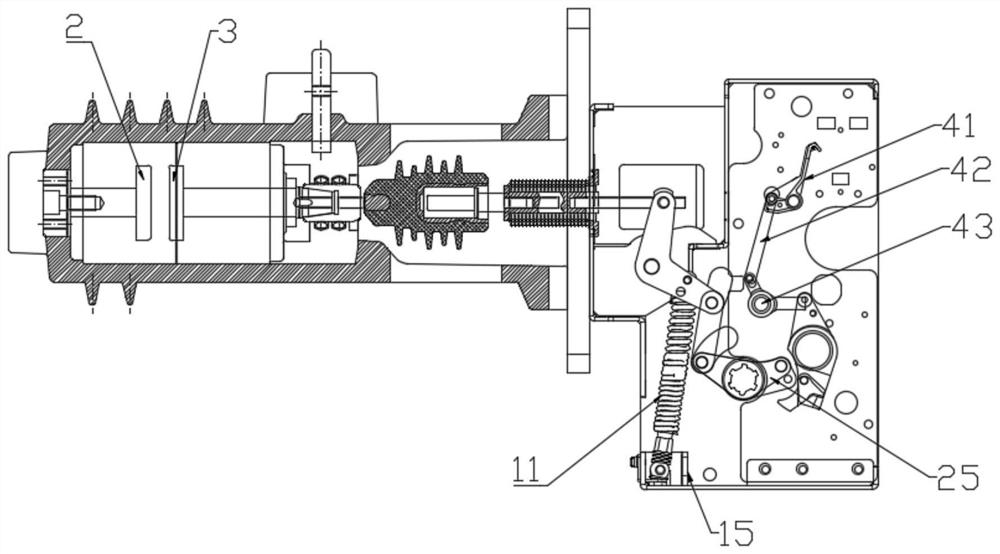

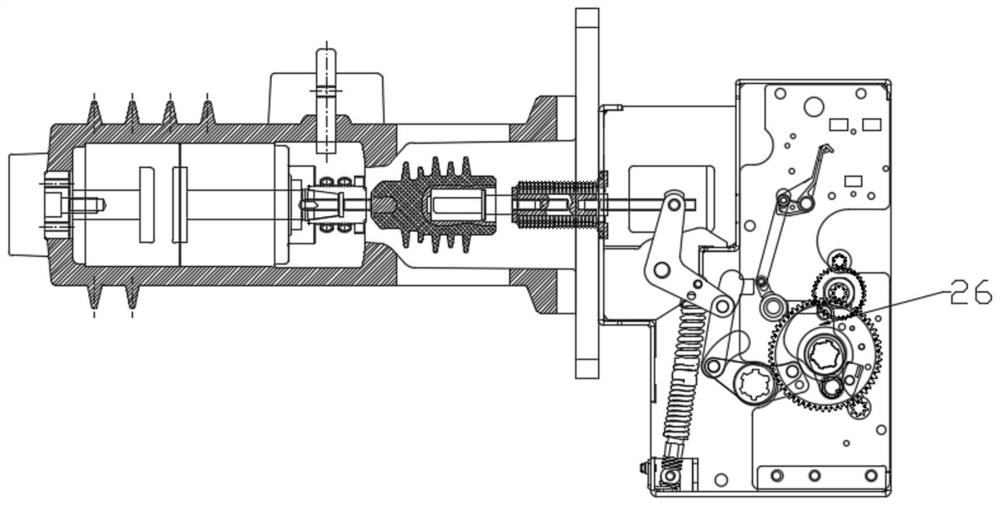

[0045] refer to Figure 1-7 , is a high-voltage vacuum circuit breaker according to the present invention, including a box support 100 and a contact system, an arc extinguishing system and an operating mechanism arranged on the box support.

[0046] The arc extinguishing system includes a vacuum interrupter 1 and an arc extinguishing structure inside it. The contact system includes a static contact 2 and a moving contact 3 inside the vacuum interrupter 1. The outer end of the static contact 2 is electrically Connect the copper outlet 5 at the static end, and the outer end of the moving contact 3 is electrically connected to the copper outlet 6 at the moving end.

[0047] The operating mechanism includes an insulating pull rod 7, a large crank arm 10, an opening spring 11, an opening operation component and a closing operation component, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com