Direct-fed plastic electroplated antenna unit

An antenna unit and plastic electroplating technology, applied in the field of communication, can solve the problems of defective parts and cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

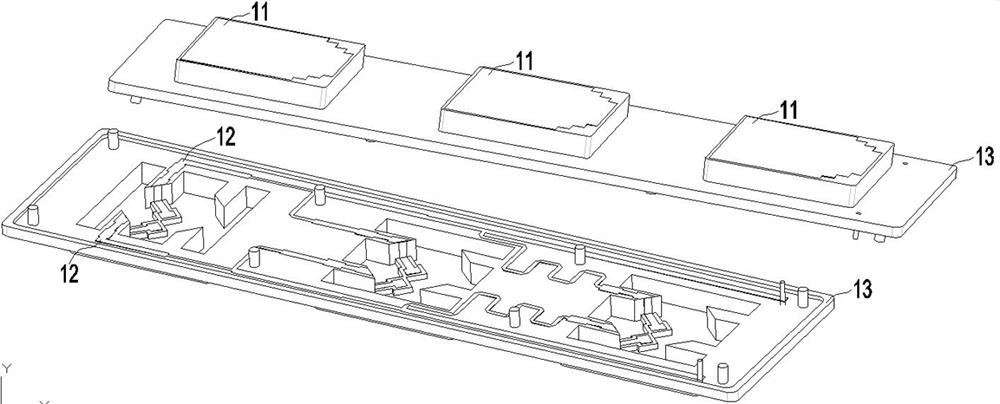

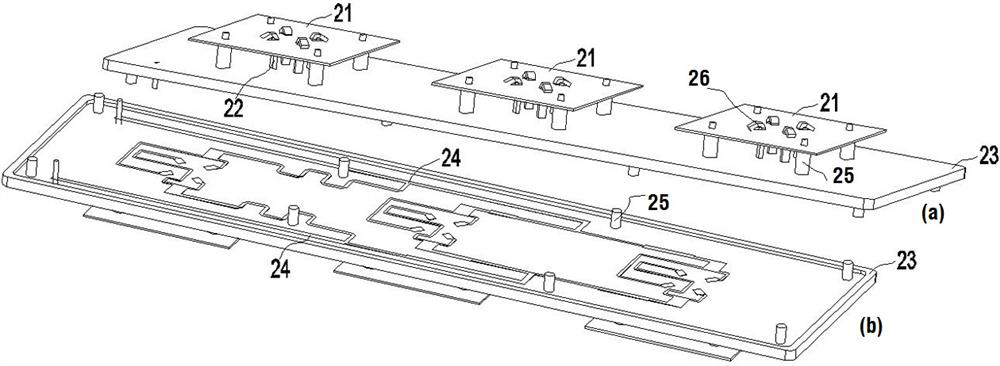

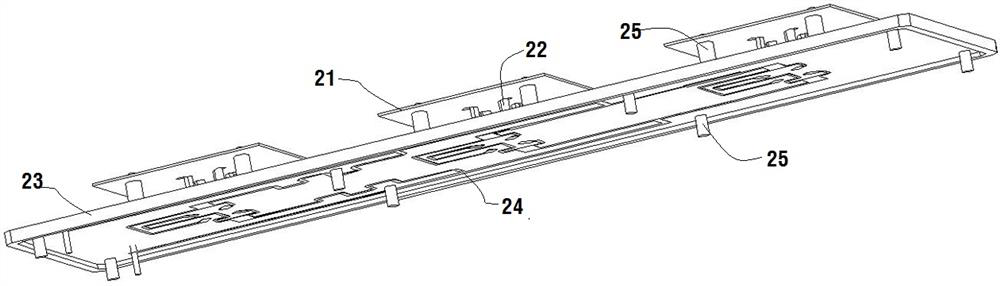

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0020] In the present invention, the antenna radiating unit adopts the direct feed mode, and the power distribution network is realized on the plastic carrier by LDS (Laser-Direct-structuring) technology, and the radiation surface and the power distribution network are directly connected through metal parts, and the operation Simple.

[0021] like Figure 2-3 as shown, figure 2 (a) and figure 2 (b) shows the views of the front and back sides of the antenna unit of the present invention, which is convenient for a more comprehensive display of the antenna unit of the present invention. The antenna unit module of the present invention includes a radiation surface 21, a plastic carrier 23, and a power division network 24 and metal parts 22, the radiating surface 21 is set on the front of the plastic carrier 23, and is supported by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com