Implementation method of linear motor for automatic sliding door

A technology of linear motors and implementation methods, which is applied in the estimation/correction of motor parameters, AC motor control, electrical components, etc., and can solve problems such as heavy current decoupling tasks, high device costs, and complex vector calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific examples.

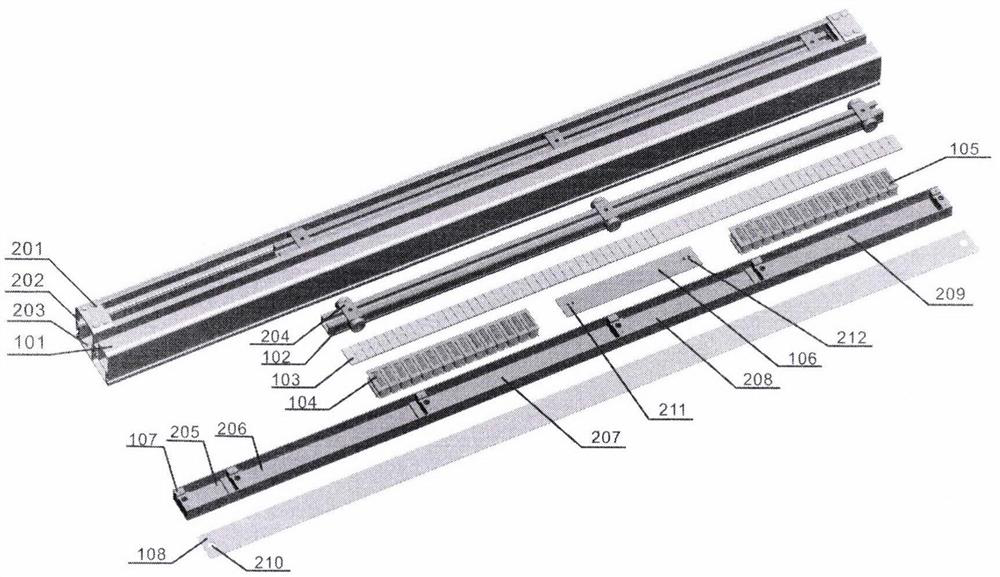

[0033] A method for realizing a linear motor for automatic sliding doors, comprising a profile 101, a mover 102, a mover magnetic steel 103, a left stator coil 104, a right stator coil 105, a motor main board 106, a stator outer cover 107, an upper cover 108, Block assembly 201, the chute 202 of the motor mover, the slot 203 of the motor stator, the pulley 204 of the mover, the rectangular grid 205 for the circuit board of the junction box, the rectangular grid 206 for the left stator coil, The rectangular grid 207 for installing the main board, the rectangular grid 208 for installing the right stator coil, the rectangular grid 209 for installing the power supply circuit board, the motor fixing hole 210, the left analog Hall device 211 on the main boa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com