A screening device for solid waste treatment

A screening device and technology for solid waste, applied in solid separation, grain processing, sieving and other directions, can solve the problems of excessively fast cutting speed, incomplete crushing, uneven grinding, etc., to prevent the cutting speed from being too fast, The effect of preventing clogging and accelerating screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

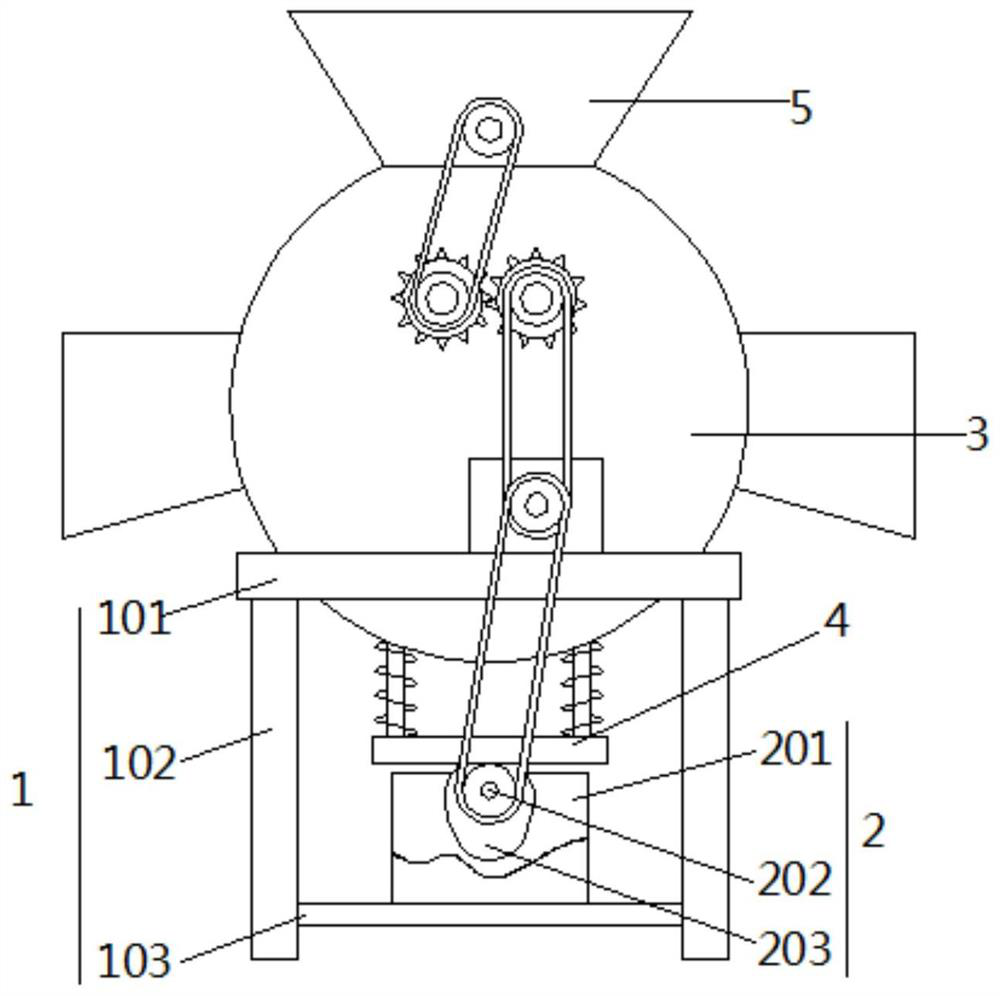

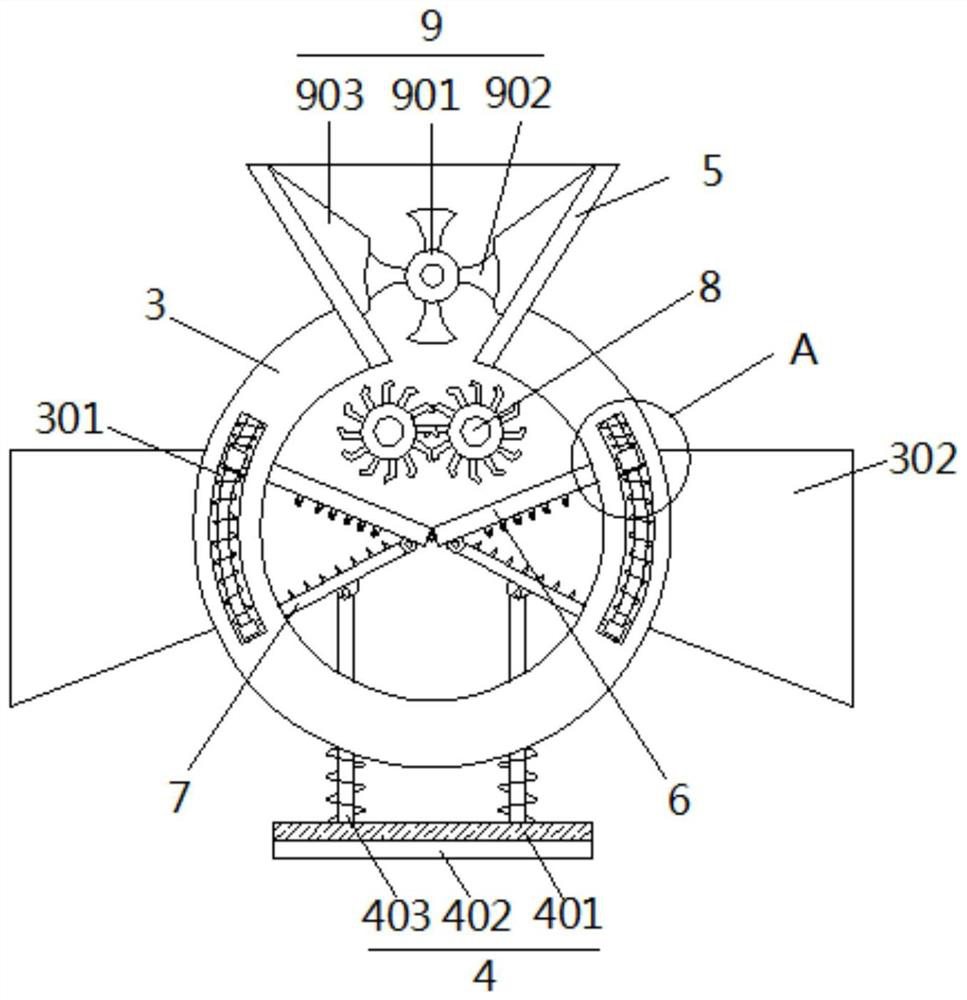

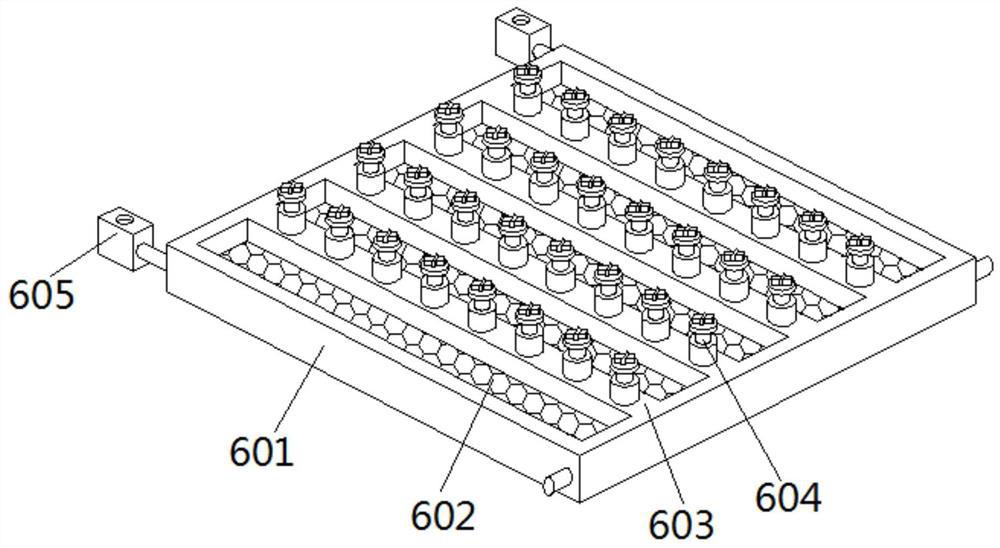

[0034] as attached figure 1 to the attached Figure 8Shown: a screening device for solid waste treatment, including a frame assembly 1, a jacking device 2, a screening drum 3, a pushing assembly 4, a feeding hopper 5, a screening device 6, a crushing device 7, and a crushing roller The wheel 8, the feeding device 9, the top of the frame assembly 1 is fixedly connected with a screening drum 3, the top of the screening drum 3 is fixedly connected with a feeding hopper 5, and a feeding device 9 is installed in the feeding hopper 5, and the screening drum 3 There are pulverizing rollers 8 connected to the left and right sides of the center of the upper end on the front and rear sides of the interior. The upper pulverizing teeth are arranged oppositely between the pulverizing rollers 8. The central axis of the pulverizing roller 8 extends to the outer end of the front side of the screening drum 3. The gears are meshed and clamped between the gears. The upper end of the central axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com