Board surface dust cleaning device for furniture production

A cleaning device and plate technology, applied to the surface coating liquid device, surface pretreatment, cleaning method using tools, etc., can solve the problem of paint falling off, affecting the appearance of furniture, corrosion resistance, poor cleaning effect, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

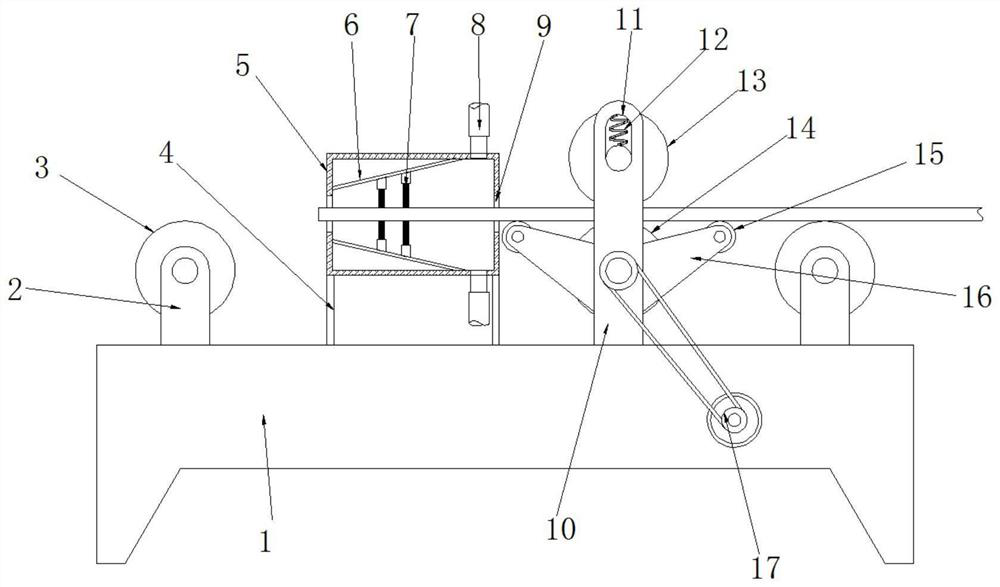

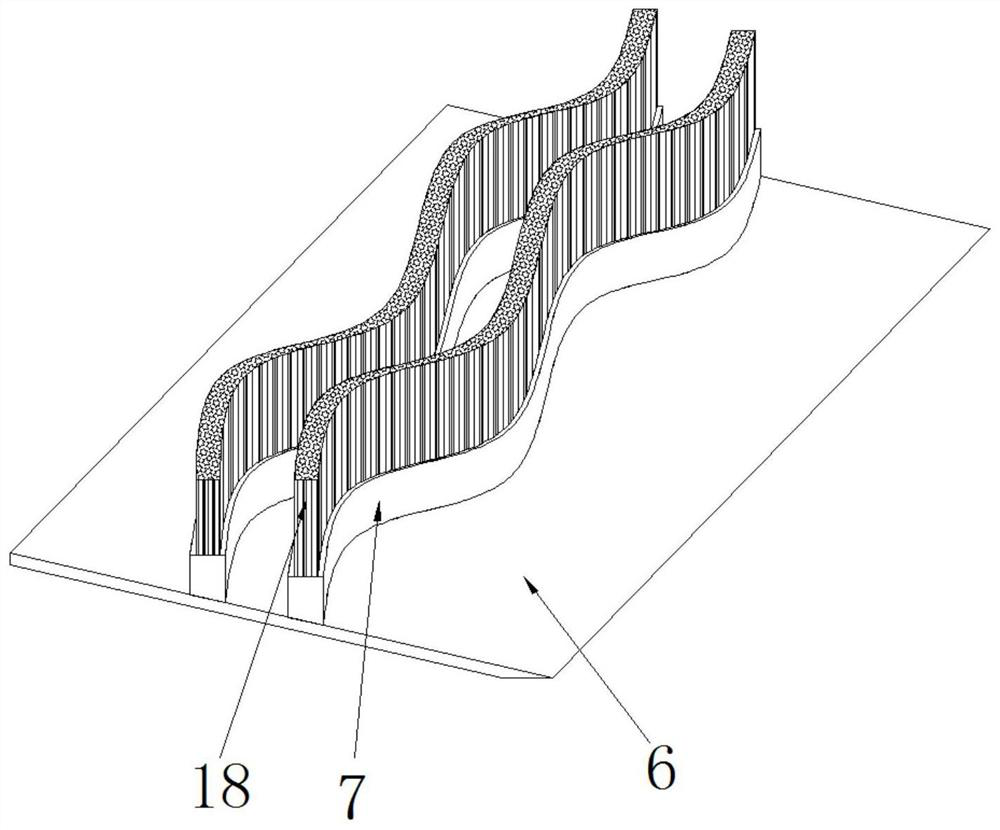

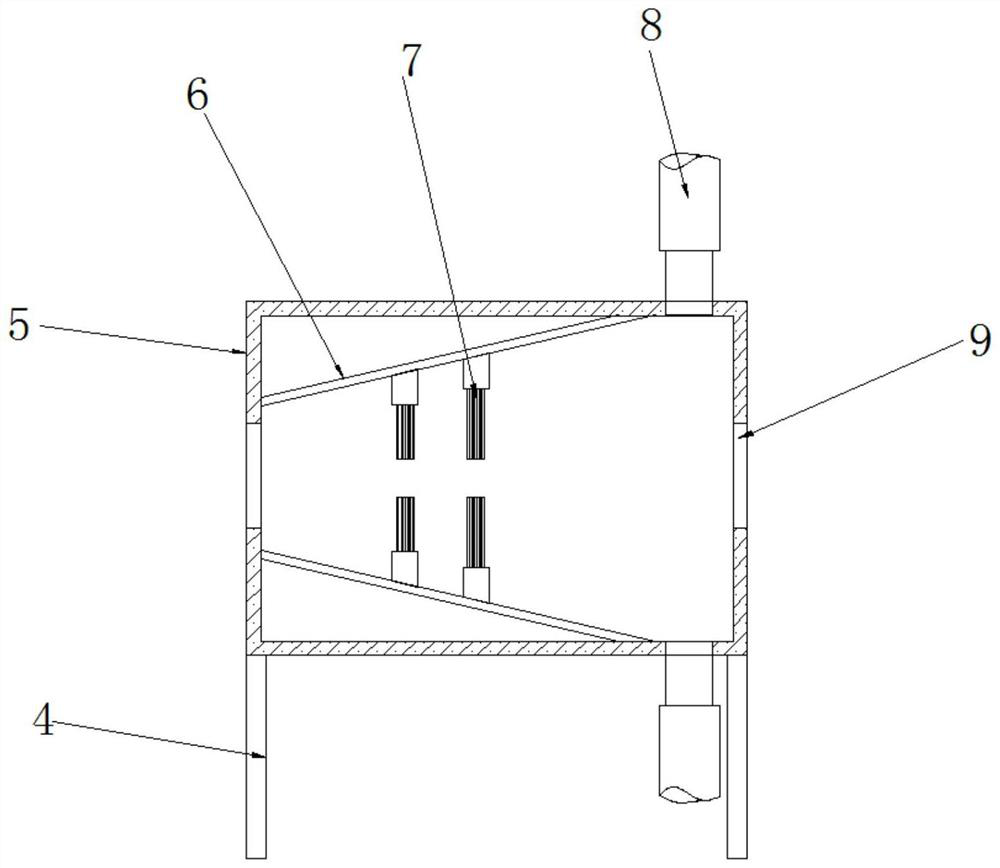

[0024] refer to Figure 1-3 , a surface cleaning device for furniture production, comprising a base 1, guide mechanisms are fixed on both sides of the top outer wall of the base 1, and a feeding mechanism is fixed on the top of the base 1, and a plurality of supports are fixed on the top outer wall of the base 1 The rod 4 and the top of the support rod 4 are fixed with a soot cleaning box 5, and the outer walls of the opposite sides of the ash cleaning box 5 are provided with feeding ports 9, and the top and bottom inner walls of the ash cleaning box 5 are fixed with symmetrically distributed material guide plates 6, and the material guide plate 6 is fixed with a plurality of dust-cleaning mechanisms, and the outer wall of dust-cleaning box 5 tops and the bottom outer wall are all fixedly plugged with dust suction pipe 8.

[0025] The guide mechanism includes two fixed plates 2, and a guide wheel 3 is rotated and inserted between the two fixed plates 2. The dust cleaning mecha...

Embodiment 2

[0028] refer to Figure 4 , a surface cleaning device for furniture production. The difference between this embodiment and Embodiment 1 is that the angle between the cleaning mechanism and the material guide plate 6 is replaced by 90 degrees, and the fixing strip 7 is perpendicular to the material guide plate 6. set up.

[0029] The working principle of this embodiment: the bristles 18 arranged obliquely can be attached to the surface of the conveyed plate, and the deformation of the bristles 18 can increase the cleaning force, thereby improving the completeness of dust removal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com