Additive manufacturing device, additive manufacturing method, profile rod and application thereof

A technology of production equipment and production method, which is applied in the field of additive production equipment, and can solve problems such as fiber breakage and deposition speed limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

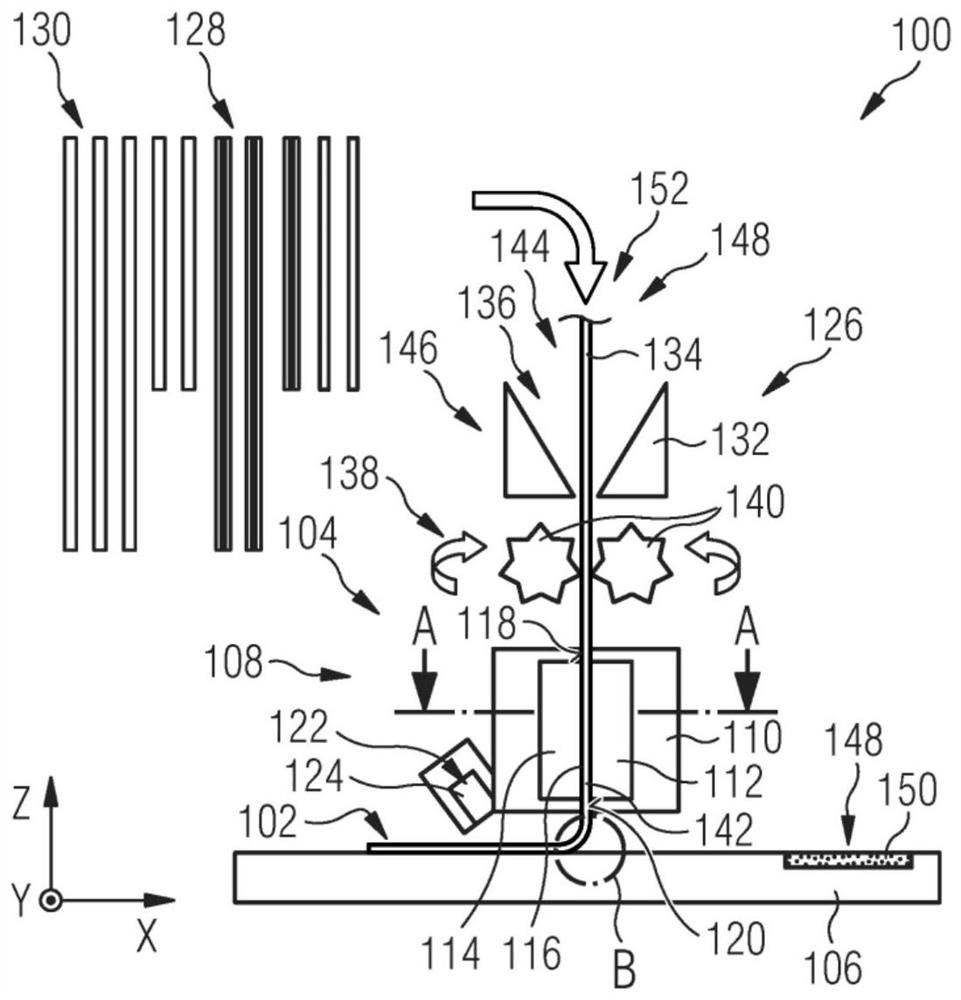

[0116] Refer below figure 2 , figure 2 An additive production device 100 is schematically shown. Additive production system 100 is designed such that component 102 is produced layer by layer. Component 102 is in particular a component of an aircraft. Component 102 may be a plastic component or a fiber reinforced plastic component or a mixture thereof. Member 102 may also contain metal inserts.

[0117] The additive production device 100 includes a print head 104 which is movable relative to a print bed 106 in a manner known per se.

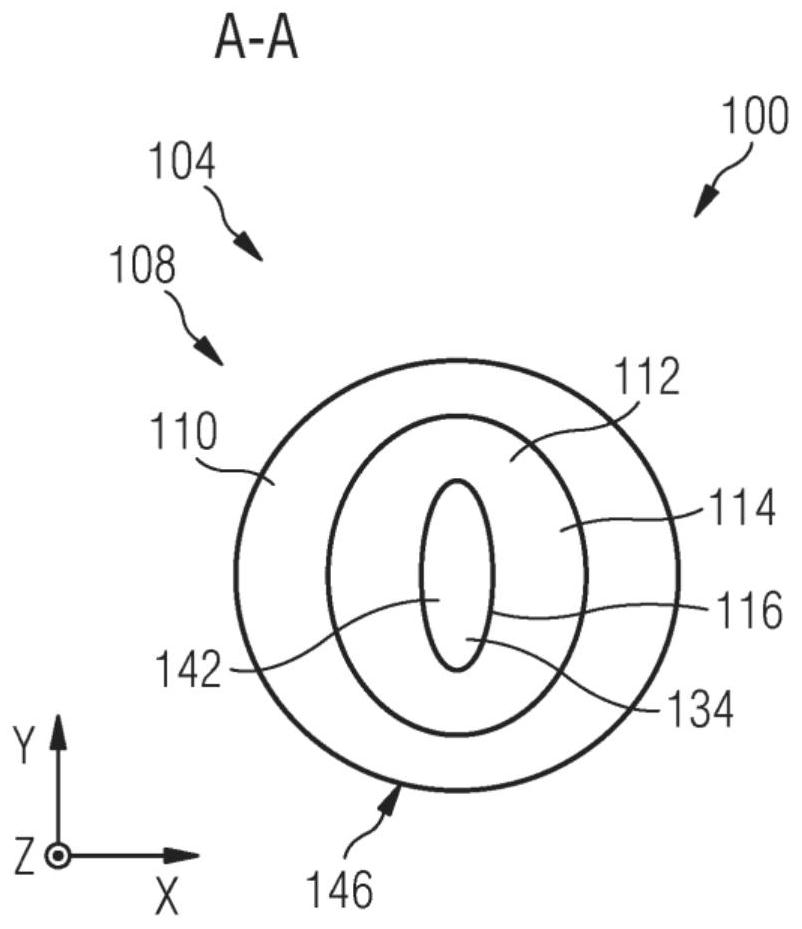

[0118] In the printhead 104, a plurality of components may be disposed. Printhead 104 may include an additive manufacturing device 108 . Additive production device 108 is designed to produce component 102 layer by layer on print bed 106 . Additive production device 108 may have a housing 110 .

[0119] The additive production device 108 includes a heating element 112 to heat the thermoplastic to its melting point or higher. The heating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com