Elevator safety detection equipment

A technology of safety detection and equipment, applied in the field of elevators, can solve the problems of inconvenient human movement, inconvenient measurement, and inability to measure gaps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

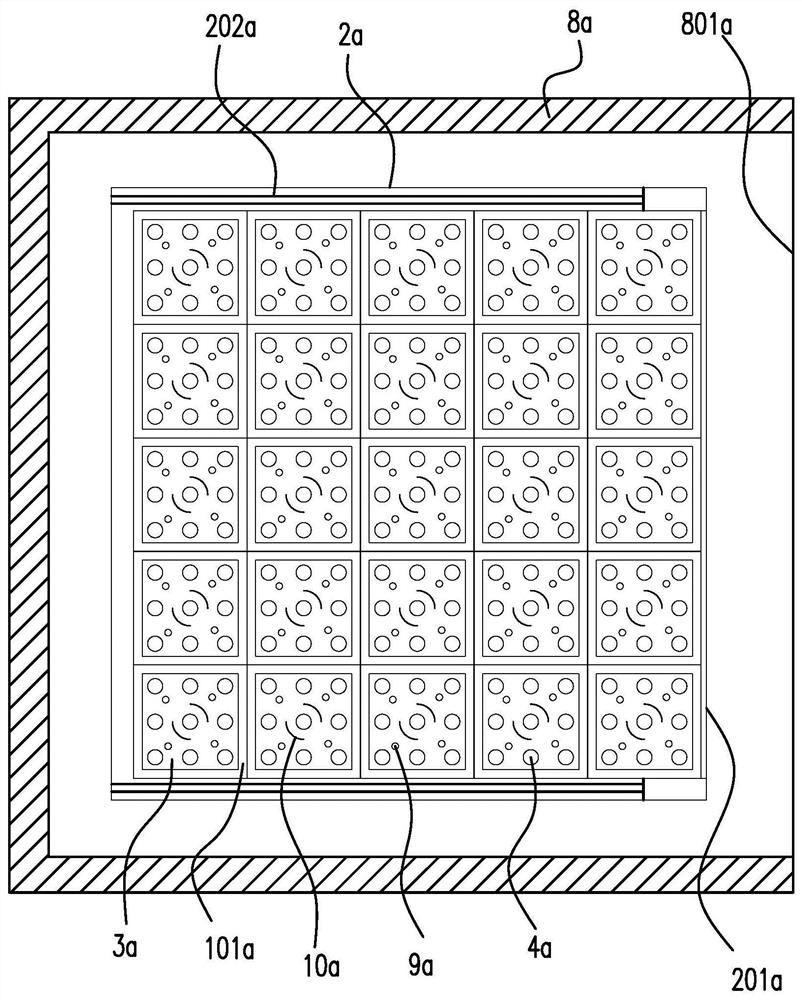

[0035] Such as figure 1 , 2 , 3, 4, 5, 6, and 7 show that a kind of elevator safety testing equipment includes a counterweight and a measuring tool, the counterweight includes a weight block 1a as a weight, and also includes a tray 2a for carrying the weight block , the transfer module 3a is arranged on the tray, the transfer module has a rectangular upper surface, the upper surface of the transfer module is embedded with freely rotatable balls 4a, to reduce the moving friction of the weight block thereon Force, the upper surface of the transmission module has a concave edge around the upper surface, that is, the edge is a downward stepped edge 101a, and the concave edges of adjacent transmission modules are adjacent to form slots, thereby forming a vertical and horizontal intersection between the arranged transmission modules. The horizontal slot and the vertical slot, the device includes a horizontal baffle 5a and a longitudinal baffle 6a that can be inserted into the slot,...

Embodiment 2

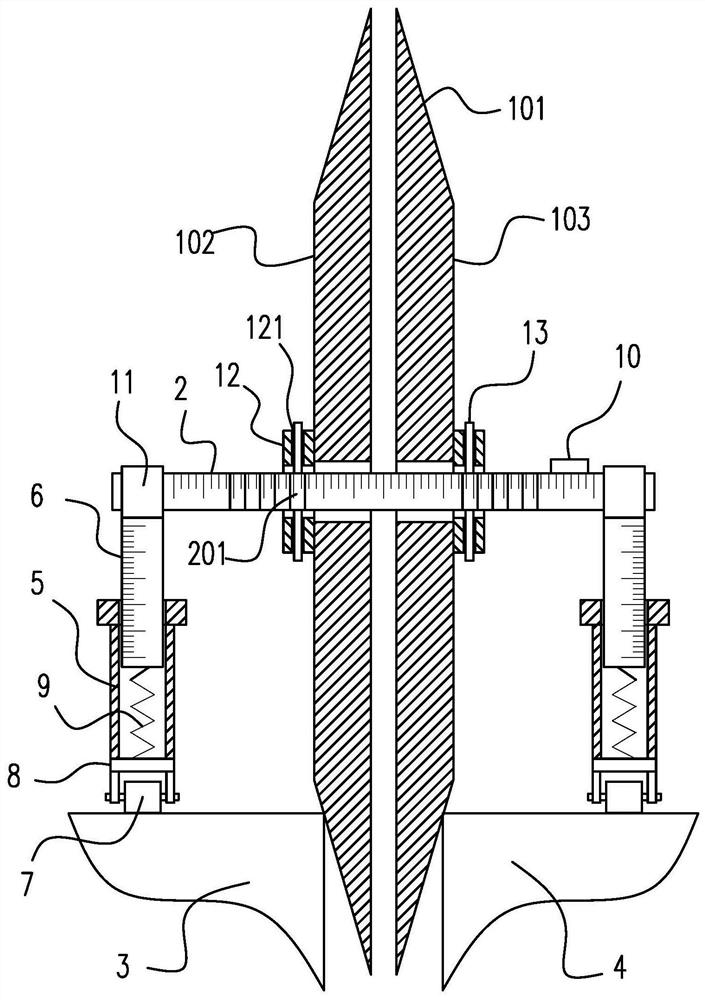

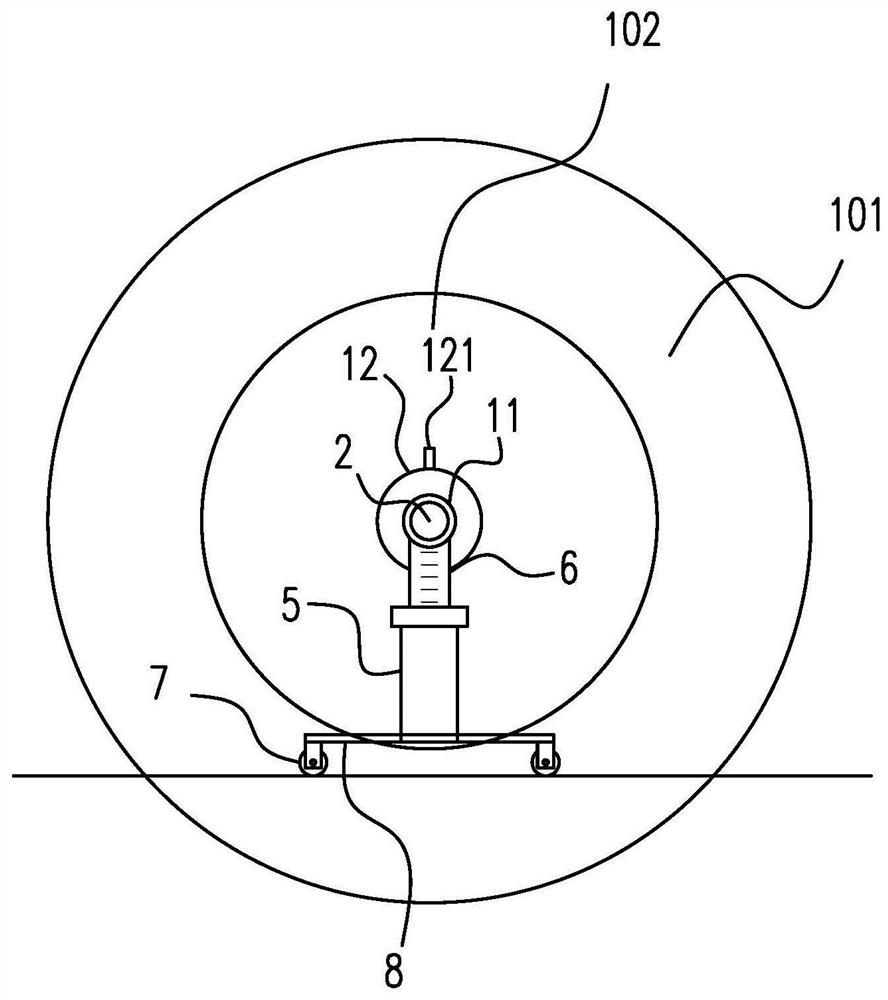

[0050] Such as Figure 8 , 9 As shown, different from the above-mentioned embodiment, the support spring between the telescopic rod and the sleeve is changed to a tension spring, that is, the two ends of the tension spring are respectively connected to the end of the telescopic rod and the bottom of the sleeve to maintain a gap between the two. A pre-tension force can be used to measure the gap in the vertical state, such as the elevator door gap, as long as the magnetic casters of the left and right brackets are respectively adsorbed on the left and right door panels 14, so that the edge of the turntable is positioned between the left and right door panels Move the support up and down at the gap to make the turntable roll up and down to detect the size change of the gap in the door panel.

[0051] The displacement adjustment device includes axial positioning sleeves 15 fixed on the left and right disk bodies, the axial positioning sleeves have internal threads, and the rotat...

Embodiment 3

[0053] Such as Figure 10 As shown, it also includes an elevator guiding stroke detection device, so as to detect the elevator guiding stroke under various counterweights. The guiding stroke detection device includes a device fixed on the top of the car 1b for detecting the distance between the top of the car and the lowest part of the elevator hoistway top 18b. Displacement sensor 2b, such as a laser rangefinder or other photoelectric distance sensors, when the displacement sensor detects that the car moves upwards, it detects the change information of the distance between the top of the car and the top of the elevator shaft, and also includes a A speed sensor 3b, which detects the speed of the car. The speed sensor can also be fixed on the counterweight 4b. The speed sensor can be a linear speed sensor or an acceleration sensor, as long as it can detect the moment when the speed changes, it can also include a control module, and the control module can adopt an embedded syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com