an assembled wall

A prefabricated, wall technology, applied in the direction of walls, buildings, building components, etc., can solve the problems of the formwork positioning of the inner wall, the thickness and dimension deviation of the inner wall, etc., and achieve the goal of ensuring consistency, good thickness and size, and avoiding changes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

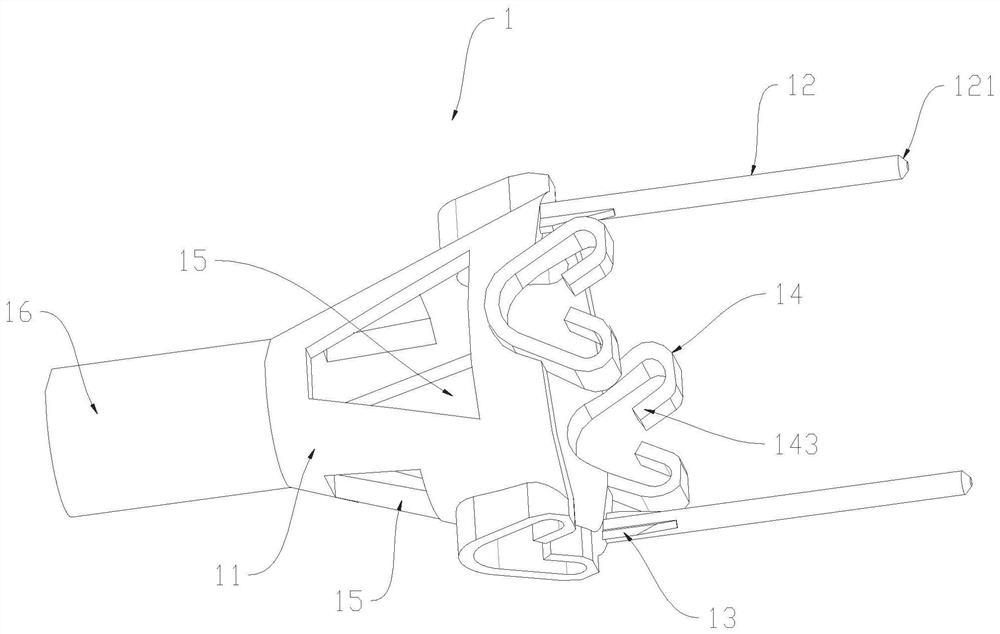

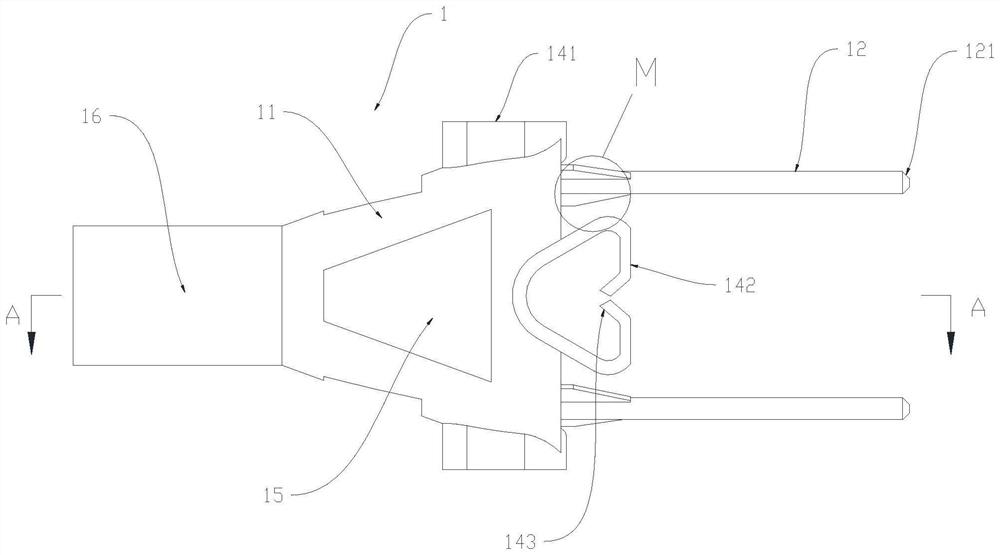

[0033] A prefabricated wall, such as Figure 1 to Figure 10 As shown, it includes an outer wall 2 and an inner wall 3 located inside the outer wall 2. The inner wall 3 is provided with a steel bar structure 10 and a connecting device 1 connected to the steel bar structure 10. The connecting device 1 is used to limit the pouring of the inner wall 3. Thickness, the connecting device 1 includes a connecting buckle 11 and a positioning rod 12, one end of the connecting buckle 11 is connected with the outer wall 2 through the first connecting part 4, the steel bar structure 10 is penetrated in the connecting buckle 11, and the shape of the connecting buckle 11 is a hollow circular platform, A lightening hole 15 for reducing the weight of the connecting buckle 11 is opened on the outer wall of the connecting buckle 11 . The connection buckle 11 is set as a hollow round platform and the weight reduction hole 15 is opened on the connection buckle 11 to reduce the weight of the connect...

Embodiment 2

[0036] A prefabricated wall, such as Figure 1 to Figure 10 As shown, on the basis of Embodiment 1, the connecting buckle 11 is provided with a second connecting portion 16 adapted to the first connecting portion 4 , and the first connecting portion 4 is screwed to the second connecting portion 16 . During construction, the first connecting part 4 is first poured in the outer wall 2, and then the second connecting part 16 is screwed on the first connecting part 4, and then the construction of the inner wall 3 is carried out, which simplifies the connection structure and the operation of construction , the second connecting part 16 is a threaded sleeve provided with an internal thread, the first connecting part 4 is a screw rod provided with an external thread at one end, and the threaded sleeve is screwed on the screw rod. The installation of the connecting device 1 and the screw rod is convenient.

[0037] Of course, in other embodiments, the second connecting part 16 may be...

Embodiment 3

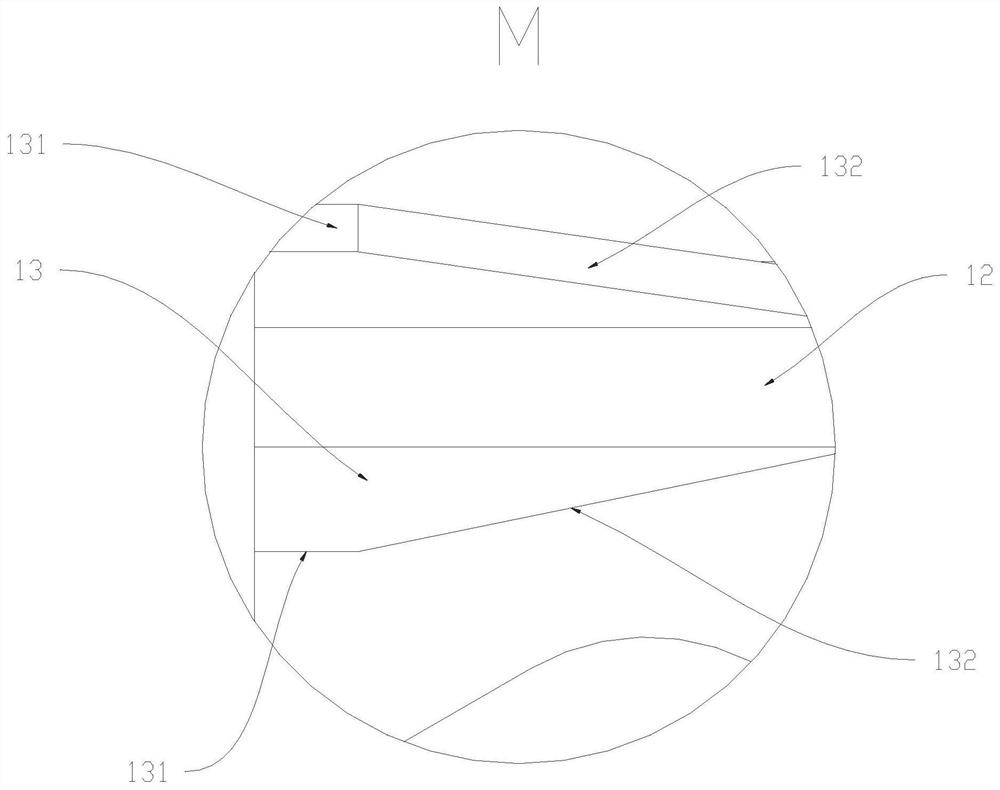

[0042] A prefabricated wall, such as Figure 1 to Figure 10 As shown, on the basis of Embodiment 2, the joint between the positioning rod 12 and the connecting buckle 11 is provided with a supporting block 13 connected to the connecting buckle 11, the supporting block 13 is connected with the outer wall of the positioning rod 12, and the supporting block 13 is axially uniform. Arranged on the positioning rod 12. The support block 13 and the positioning rod 12 are integrally formed, and the shear force of the positioning rod 12 in the vertical direction is enhanced through the support block 13, so as to prevent the positioning rod 12 from being bent by the extrusion of the inner wall formwork, and at the same time strengthen the right end of the positioning rod 12 and the connection The connection strength of the buckle 11, thereby enhancing the overall strength of the positioning rod 12 in the construction process, the inner end surface of the support block 13 is attached to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com