Bailey steel truss supporting device for shallow round bin construction and construction method thereof

A supporting device and Bailey frame technology, which is applied in the direction of building structure support, building structure support, large-capacity bulk material storage, etc., can solve the problems of long construction period, short construction period, many manpower and material resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

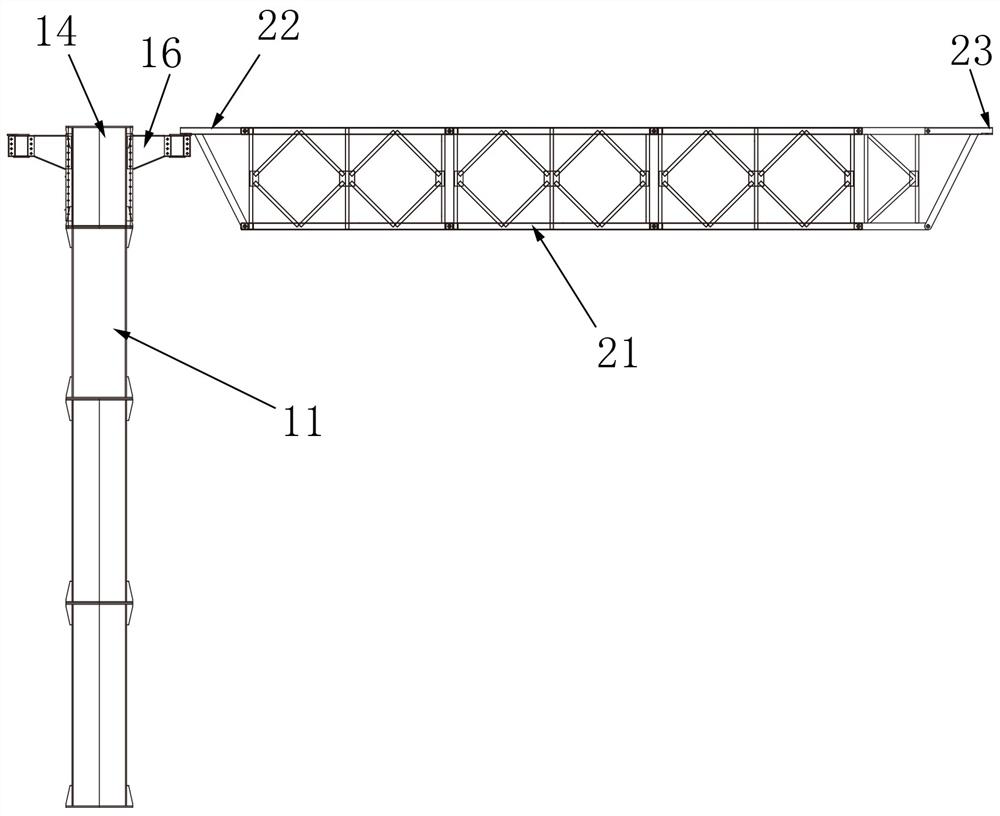

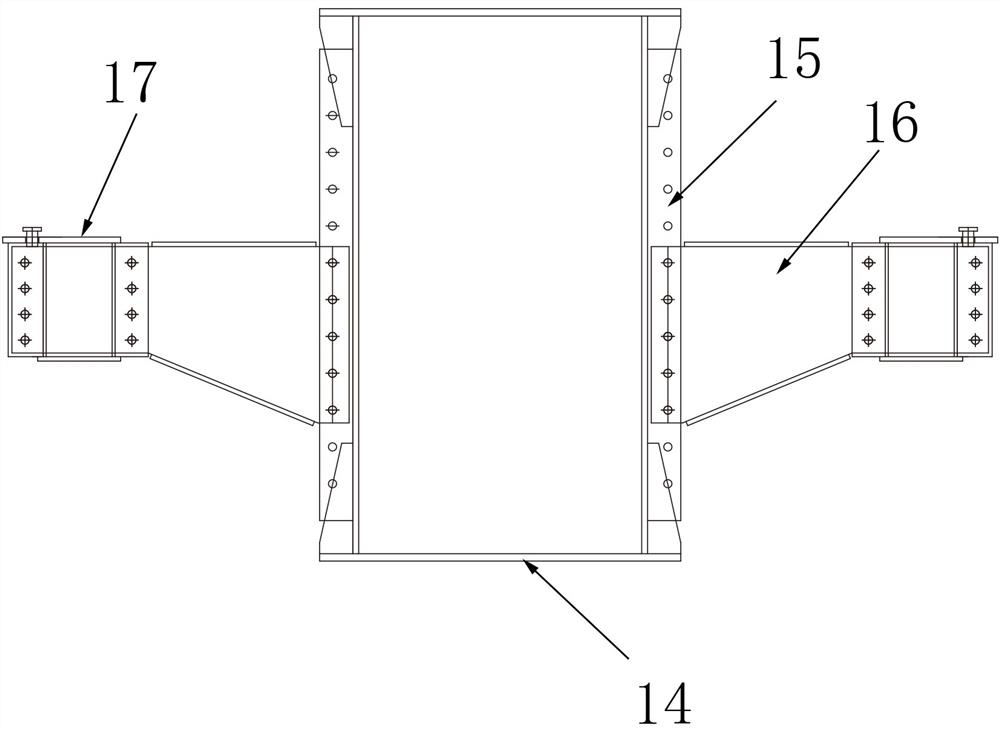

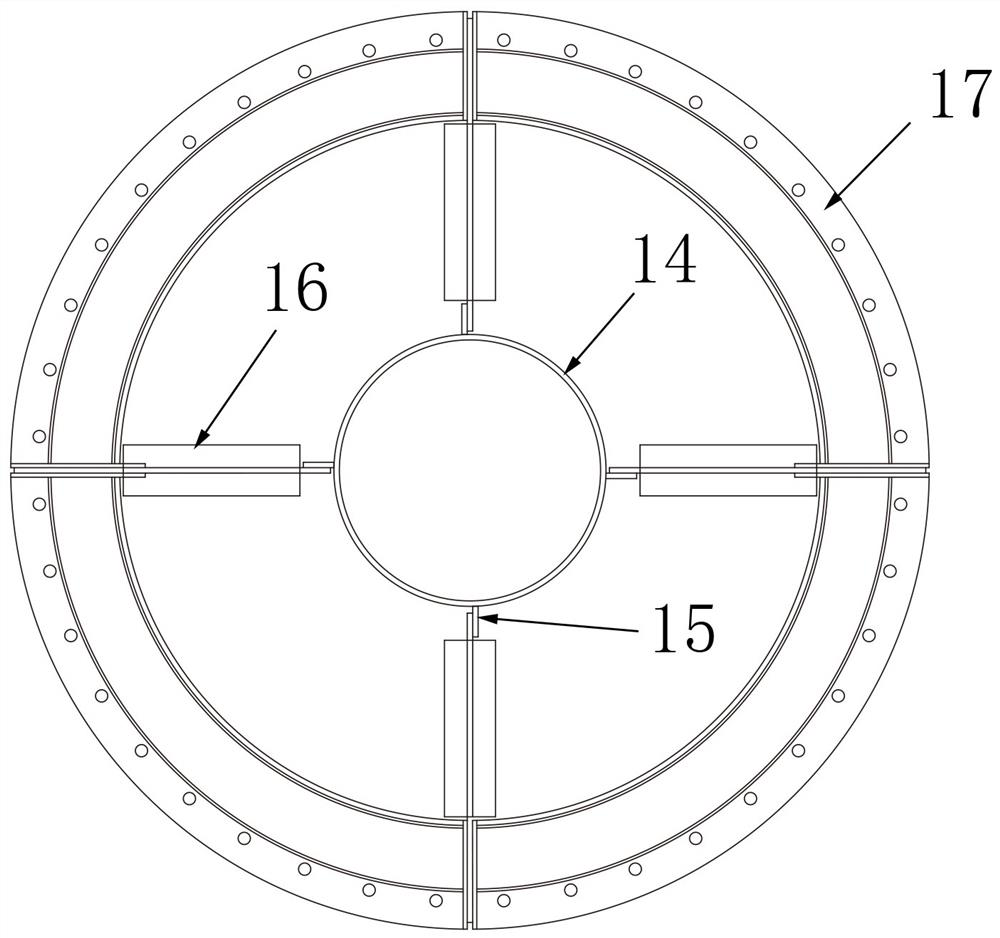

[0024] See attached picture. The Bailey steel truss support device described in this embodiment includes a central support column 1 and a plurality of composite Bailey frames 2, and the composite Bailey frames 2 are evenly installed around the central support column 1; the central support column 1 includes a top The umbrella-shaped bracket and the multi-section standard column section 11, the column standard section 11 includes a tubular body, the upper and lower ends of the tubular body are provided with an annular connection surface 12, and a reinforcing block 13 is provided between the tubular body and the annular connection surface, and the adjacent column standard section The ring-shaped connecting surfaces are bonded and fixedly connected by high-strength bolts; the umbrella-shaped support includes a tubular first support 14, and four strip-shaped mounting surfaces 15 are evenly arranged on the outer peripheral wall of the first support 14, and each mounting surface A se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com