Automatic-reset support equipped with stepless regulating friction energy dissipation device

A friction energy-consuming, stepless adjustment technology, applied in building components, building types, earthquake resistance, etc., can solve problems such as hindering movement, hindering the self-resetting ability of supports, and restricting the promotion and application of self-resetting supports.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

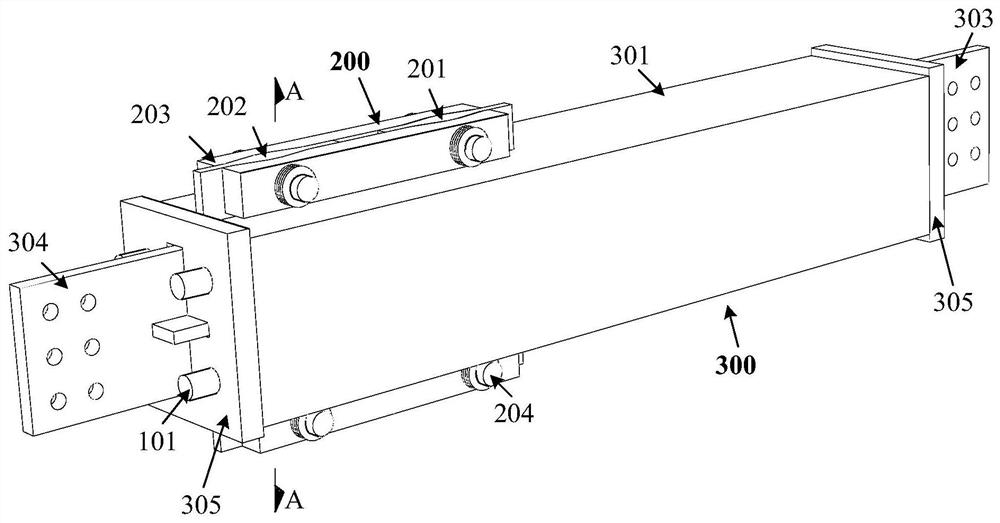

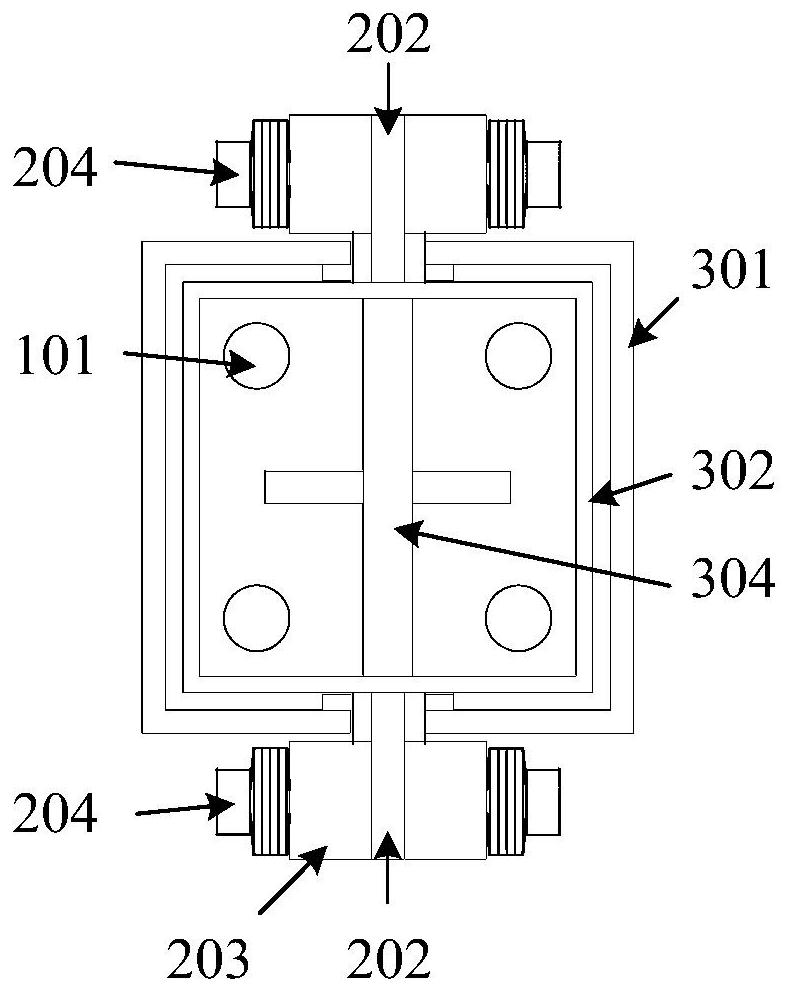

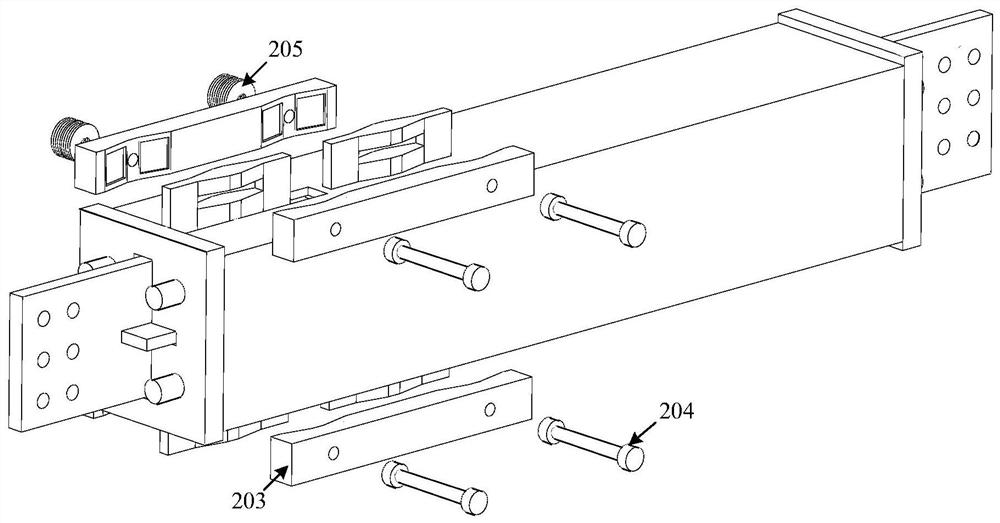

[0055] Such as Figure 1-Figure 7 As shown, a new type of self-resetting support equipped with a stepless adjustment frictional energy dissipation device includes a self-resetting mechanism 100 , a frictional energy dissipation mechanism 200 , and a connecting force transmission mechanism 300 . During the installation process, the first inner friction plate 201 is fixedly connected to the surface of the outer sleeve, and the second inner friction plate 202 is fixedly connected to the surface of the inner sleeve, and the two inner friction plates are fixed along the same straight line;

[0056] Subsequently, the inner sleeve 302 is placed in the outer sleeve 301, and the end plate 305 is placed on both ends of the inner sleeve 302 and the outer sleeve 301, and is in contact with the ends of the inner and outer sleeves 301, and finally the self-resetting The assembly is tensioned and anchored between end plates 305 .

[0057] At the same time, friction plates can also be instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com