Drainage system for overmining area of coal mine

A drainage system and mining area technology, applied in drainage, mining equipment, earth square drilling and mining, etc., can solve problems such as blockage, drainage effects, and inability to handle soil residues well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

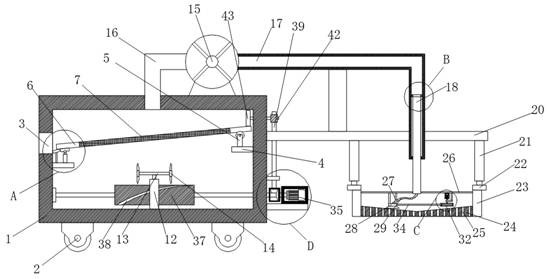

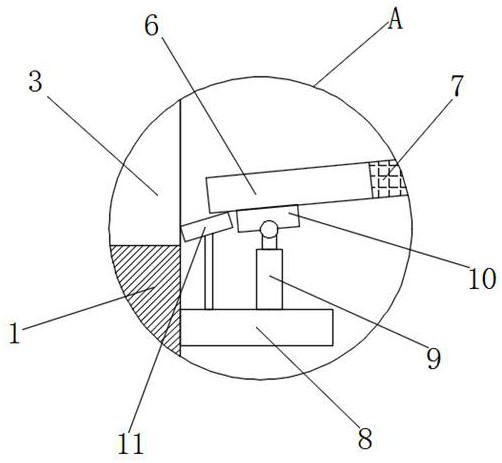

Embodiment 1

[0029] refer to Figure 1-6 , a drainage system for a coal mine overexploitation area, including a box body 1, a plurality of bottom wheels 2 are symmetrically fixedly installed on the bottom of the box body 1, to facilitate the movement of the whole device, and a filter residue port 3 is opened on one side of the box body 1, and the box body 1 A baffle 6 is movable installed in the body 1, and a filter screen 7 is fixedly installed on the baffle 6, which can effectively separate the pumped mud residue. A first fixed plate 8 is fixedly installed on the inner wall of one side of the first fixed plate 8, and the bottom end of the telescopic rod 9 is fixedly mounted on the top of the first fixed plate 8, and the top end of the telescopic rod 9 is movably installed on the bottom of the first connecting plate 10, and the first fixed plate 8 The top of the plate 8 is fixedly equipped with a slant plate 11, and a first support plate 12 is slidably installed on the bottom inner wall o...

Embodiment 2

[0040] refer to Figure 1-6 , a drainage system in a coal mine overexploitation area, including a box body 1, the bottom of the box body 1 is symmetrically fixed with several bottom wheels 2 by welding to facilitate the movement of the whole device, and a filter residue port 3 is opened on one side of the box body 1 A baffle plate 6 is movable installed in the box body 1, and a filter screen 7 is fixedly installed on the baffle plate 6 by welding, which can effectively separate the pumped mud residue, and the bottom of the baffle plate 6 is slidingly installed with a first connecting plate 10 A first fixed plate 8 is fixedly installed by welding on one side inner wall of the box body 1, and the bottom end of the telescopic rod 9 is fixedly installed on the top of the first fixed plate 8 by welding, and the top end of the telescopic rod 9 is movably installed on the first connection. The bottom of the plate 10, the top of the first fixed plate 8 is fixedly installed with a slan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com