Energy accumulator liquid filling integrated valve

An accumulator, integrated valve technology, applied in the direction of fluid pressure actuation device, servo motor assembly, mechanical equipment, etc., can solve the problem of not being able to meet the speed requirements, and achieve effective circulation, cost saving, and volume reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below according to the accompanying drawings and embodiments.

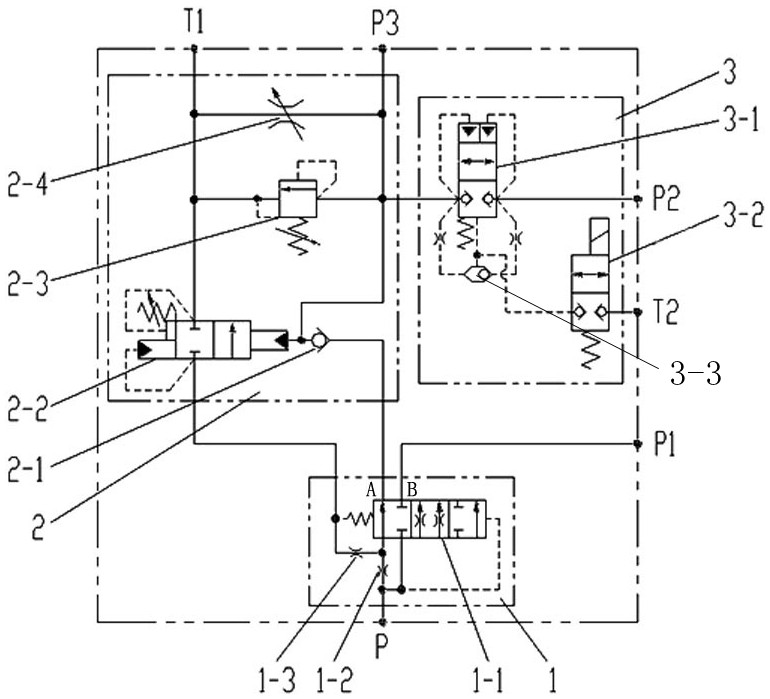

[0015] Such as figure 1 As shown, an accumulator liquid charging integrated valve includes a flow priority valve 1, a liquid charging valve 2 and an electromagnetic switching valve group 3, and the flow priority valve 1 includes a three-position four-way valve 1-1 and a damping II 1-3 , the oil inlet of the three-position four-way valve 1-1 is connected to the oil port P. In this embodiment, a There is damping I1-2, here damping I1-2 can also be replaced by adjustable throttle valve I, adjustable throttle valve I facilitates the adjustment of the flow rate of the liquid filling integrated valve; the liquid filling valve 2 includes a one-way valve 2-1 , two-position two-way valve Ⅰ2-2, relief valve 2-3 and adjustable flow valve II2-4, oil port A of three-position four-way valve 1-1 is connected with the oil inlet port of one-way valve 2-1 , the oil outlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com