Control method of kitchen air conditioner

A control method and technology for kitchens, applied in the direction of control input involving air characteristics, space heating and ventilation control input, heating and ventilation control system, etc., can solve the problems of supercooling, insufficient conversion, inconsistent air flow rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

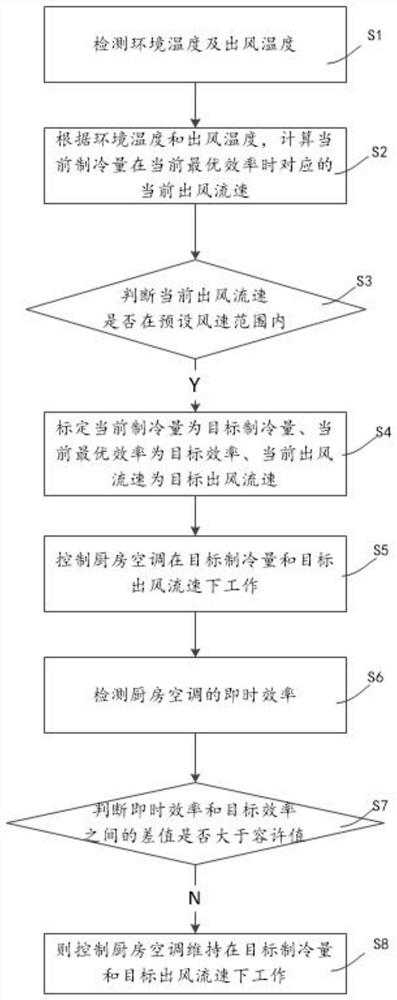

[0034] See attached figure 1 A control method of a kitchen air conditioner according to the present invention includes the following steps:

[0035] Step S1: Detect the ambient temperature and the air outlet temperature;

[0036] Step S2: According to the ambient temperature and the outlet air temperature, calculate the current outlet air flow rate corresponding to the current cooling capacity at the current optimal efficiency;

[0037] Step S3: judging whether the current air flow speed is within the preset wind speed range;

[0038] Step S4: If the current air flow speed is within the preset wind speed range, calibrate the current cooling capacity as the target cooling capacity, and the current air flow speed as the target air flow speed; if the current air flow speed is not within the preset wind speed range, calculate the next The next air flow rate corresponding to the cooling capacity at the next optimal efficiency;

[0039] Step S5: Control the kitchen air conditione...

Embodiment 2

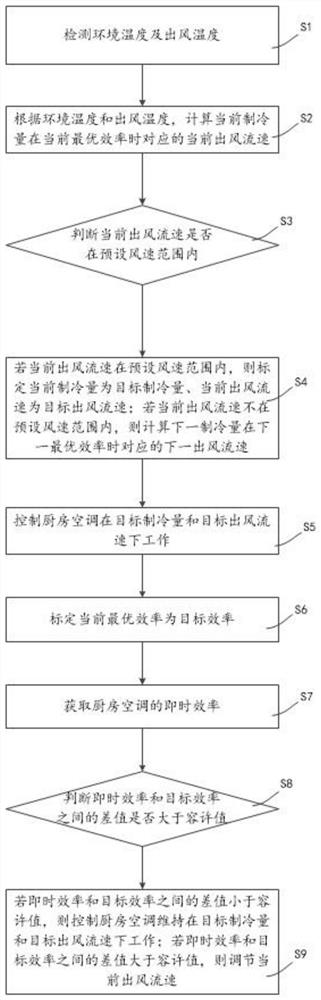

[0052] see figure 2 It shows a control method of a kitchen air conditioner, the difference from Embodiment 1 is that after S5 controls the kitchen air conditioner to work under the target cooling capacity and the target air outlet flow rate, the following steps are further included:

[0053] Step S6: Calibrate the current optimal efficiency as the target efficiency;

[0054] Step S7: Obtain the instant efficiency of the kitchen air conditioner;

[0055] Step S8: judging whether the difference between the immediate efficiency and the target efficiency is greater than the allowable value;

[0056] Step S9: If the difference between the immediate efficiency and the target efficiency is less than the allowable value, control the kitchen air conditioner to maintain the target cooling capacity and the target air flow rate; if the difference between the immediate efficiency and the target efficiency is greater than the allowable value, Then adjust the current air flow rate.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com