Moving chassis distance measuring method and system during advancing

A ranging method and technology between traveling, which is applied in the field of moving chassis ranging between traveling, and can solve the problem of inability to measure the distance in real time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] A moving chassis distance measurement method during travel includes a single-chassis measurement method and a double-chassis measurement method.

[0039] Such as figure 1 As shown, the single-chassis measurement method includes the following steps:

[0040] A1. Install the positioning unit on the chassis to obtain the coordinate values of the chassis on the Cartesian coordinate axis, and connect the positioning unit and the networking module to the data processing unit;

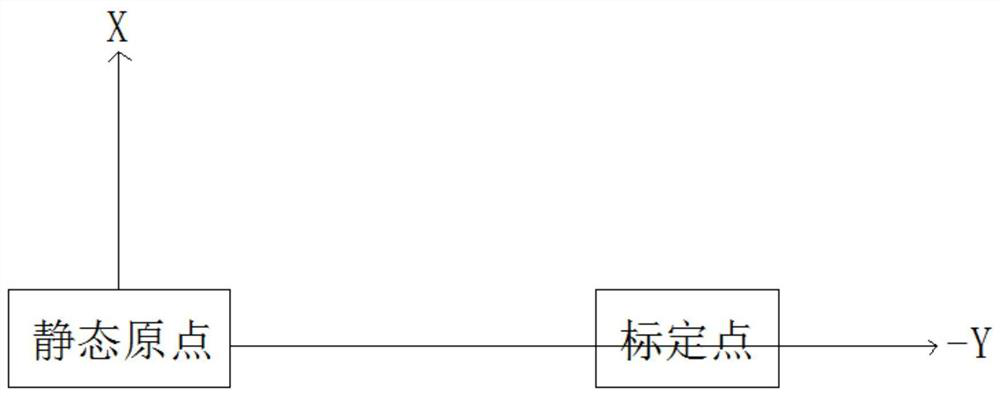

[0041] A2. Define the static origin and calibration point, place the chassis at the static origin and calibration point to output the coordinates on the corresponding Cartesian coordinate axis through the positioning unit on the chassis, and calibrate the straight line formed by the static origin and calibration point as Y axis;

[0042] A3. After the Y-axis is calibrated, the X-axis is obtained by rotating the positive half-axis of the Y-axis 90° clockwise with the static origin as the center, thu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com