Fracture network shear-two-phase flow test device and test method

A fracture network and test device technology, applied in the field of rock mechanics and fluid mechanics, can solve the problem of failure to simulate fracture network-shear two-phase flow related experiments, failure to reveal the shear-two-phase flow mechanism of fracture network, and inability to simulate different Shear displacement etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

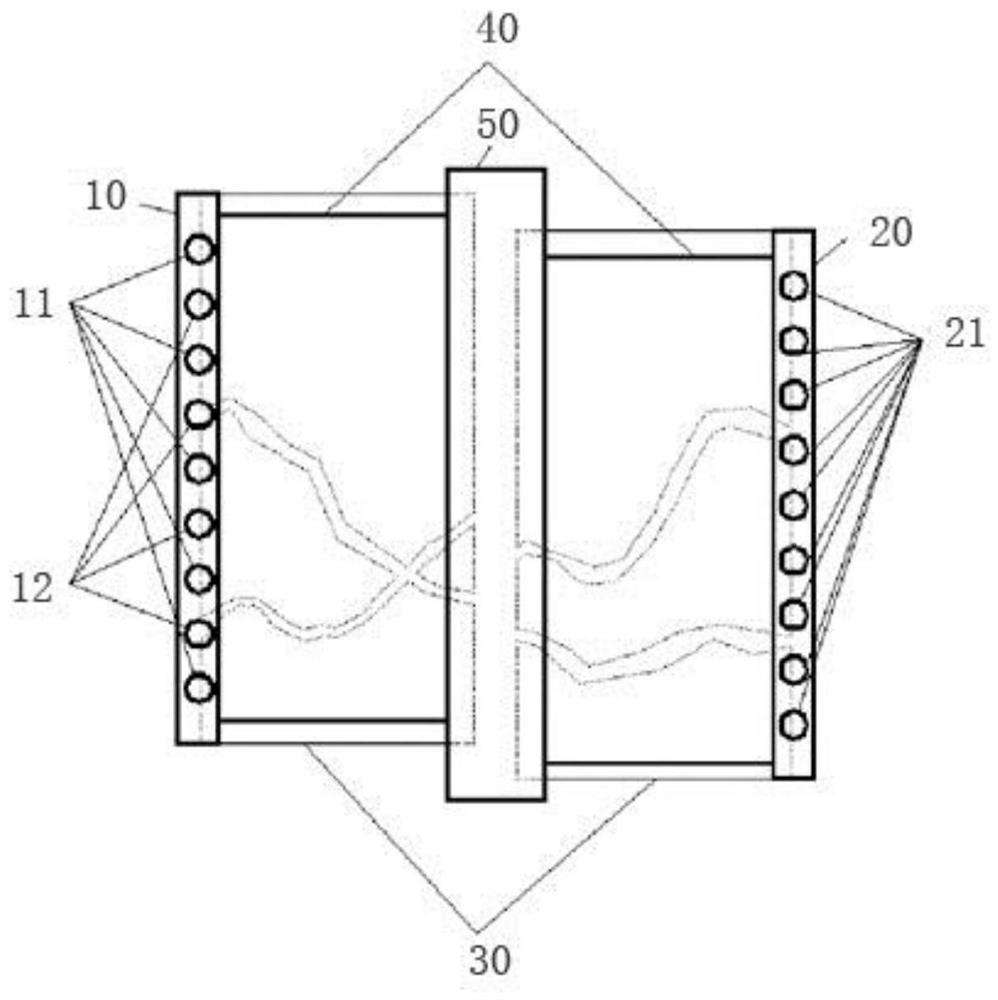

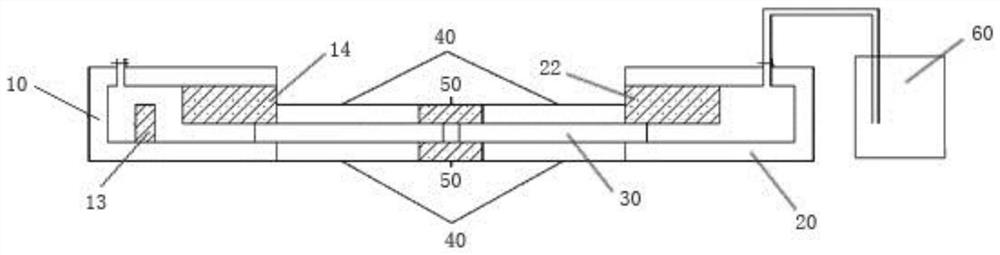

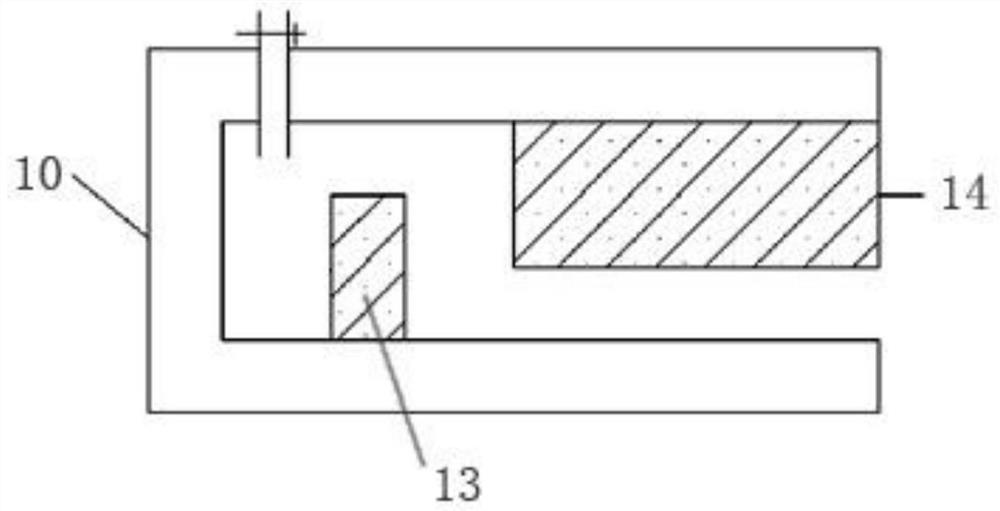

[0037] This application provides a figure 2 The preferred embodiment 1 shown is a fracture network shear-two-phase flow test device, including the model boundary isobaric water injection and gas injection device 10, the model boundary water vapor collection device 20, the glass fracture network Model 30, wide cover plate 40, narrow cover plate 50 and described moisture collection tank 60, these parts are assembled as above, wherein:

[0038]The fissure network model 30 made of glass is prepared by cutting with a water knife or drawing with a glass knife or physically hitting the fissure network on a glass plate; when shearing, only half of the detachable model needs to be cut along the x Axis or Y-axis movement can meet the required opening and displacement, without the need to move both halves of the detachable model; Figure 4 As shown, the wide cover plate 40 is used to clamp the glass fracture network model 30, the narrow cover plate 50 is used to clamp the sheared part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com