Quantitative method for center porosity or shrinkage cavity of casting blank

A technology of central looseness and shrinkage cavity, which is applied in measuring devices, processing detection response signals, and using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., to achieve accurate judgment, reduce errors, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

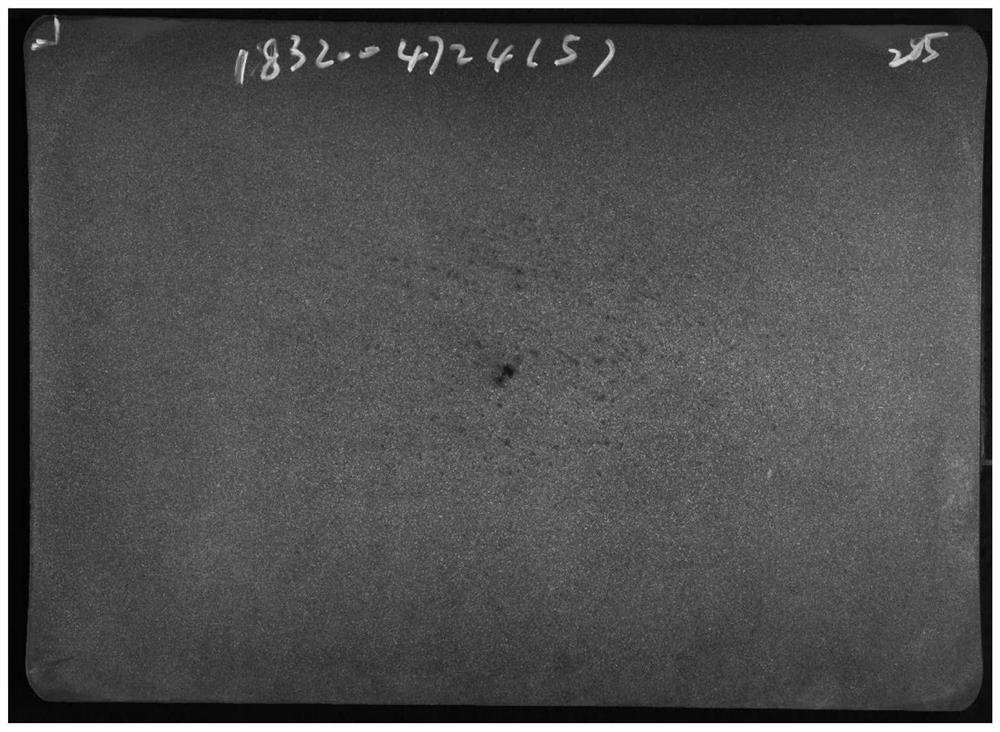

[0036] The method of the present invention measures the degree of porosity and shrinkage cavity in the center of furnace number 3623-287si.

[0037] (1) Sampling and sample preparation: take an 87si billet sample with a cross-section of 398mm*284mm and a height of 130mm, and process the surface of the billet to make the surface of the billet sample smooth and parallel to the top and bottom;

[0038] (2) Ultrasonic water immersion non-destructive testing: the 87si billet sample is subjected to ultrasonic water immersion non-destructive testing;

[0039] (3) Data calculation; set the loose or shrinkage cavity in the center of the slab as a single sphere, and count the size and number of spheres. After statistics, there are 28 holes with a radius of 15 μm and 3 holes with a radius of 25 μm. According to formula a) The calculated hole volume V hole is 0.00055m 3 , according to the formula b) vcast = abc calculate the billet volume Vcast is 0.014m 3 , according to the formula c)...

Embodiment 2

[0041] The method of the present invention measures the degree of porosity and shrinkage cavity in the center of furnace number 1835-592si.

[0042] (1) Sampling and sample preparation: take a 92si billet sample with a cross section of 398mm*284mm and a height of 130mm, and process the surface of the billet so that the surface of the billet sample is smooth and the upper and lower sides are parallel;

[0043] (2) Ultrasonic water immersion non-destructive testing: the 92si billet sample is subjected to ultrasonic water immersion non-destructive testing;

[0044] (3) Data calculation; set the loose or shrinkage cavity in the center of the slab as a single sphere, and count the size and number of spheres. After statistics, there are 20 holes with a radius of 15 μm and 6 holes with a radius of 25 μm. According to formula a) The calculated hole volume V hole is 0.000686m 3 , according to the formula b) vcast = abc calculate the billet volume Vcast is 0.014m 3 , according to the...

Embodiment 3

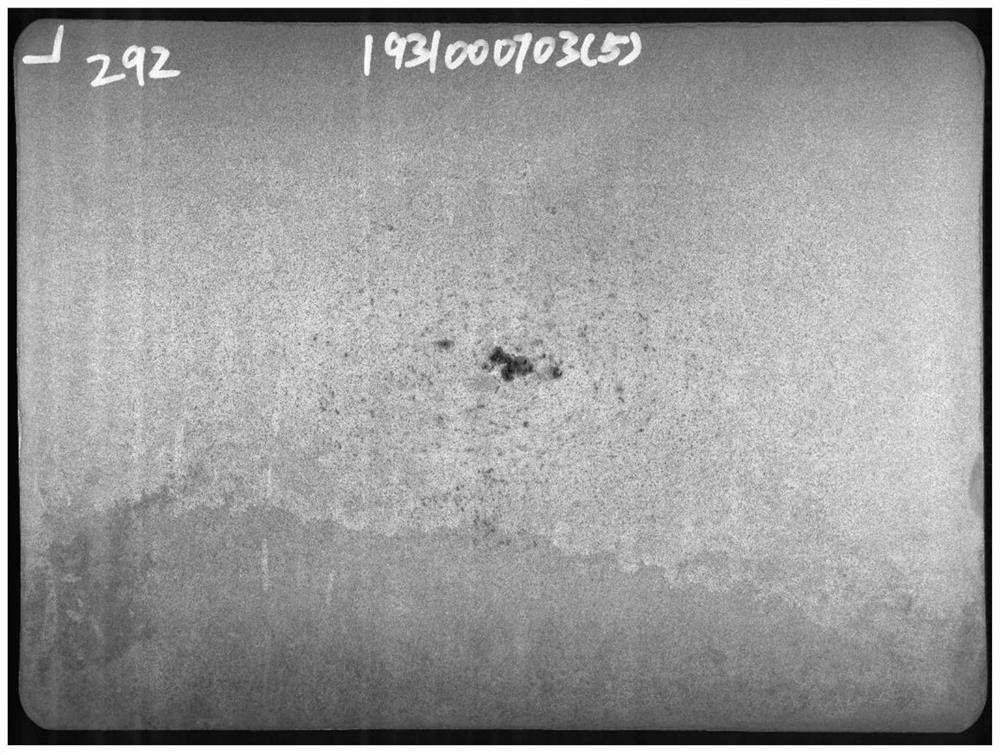

[0047] The method of the present invention measures the furnace number is 1931-592si central porosity and shrinkage cavity degree.

[0048] (1) Sampling and sample preparation: take a 92si billet sample with a cross section of 398mm*284mm and a height of 130mm, and process the surface of the billet so that the surface of the billet sample is flat and the upper and lower sides are parallel;

[0049] (2) Ultrasonic water immersion non-destructive testing: the 92si billet sample is subjected to ultrasonic water immersion non-destructive testing;

[0050] (3) Data calculation; set the loose or shrinkage cavity in the center of the slab as a single sphere, and count the size and number of spheres. After statistics, there are 25 holes with a radius of 15 μm and 6 holes with a radius of 25 μm. According to formula a) The calculated hole volume V hole is 0.000728m 3 , according to the formula b) vcast = abc calculate the billet volume Vcast is 0.014m 3 , according to the formula c)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com