Point distribution method and system for complex special-shaped holes

A special-shaped hole, complex technology, applied in the direction of geometric CAD, etc., can solve the problems of low degree of automation, insufficient automatic distribution of special-shaped holes, and low efficiency of measuring point planning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

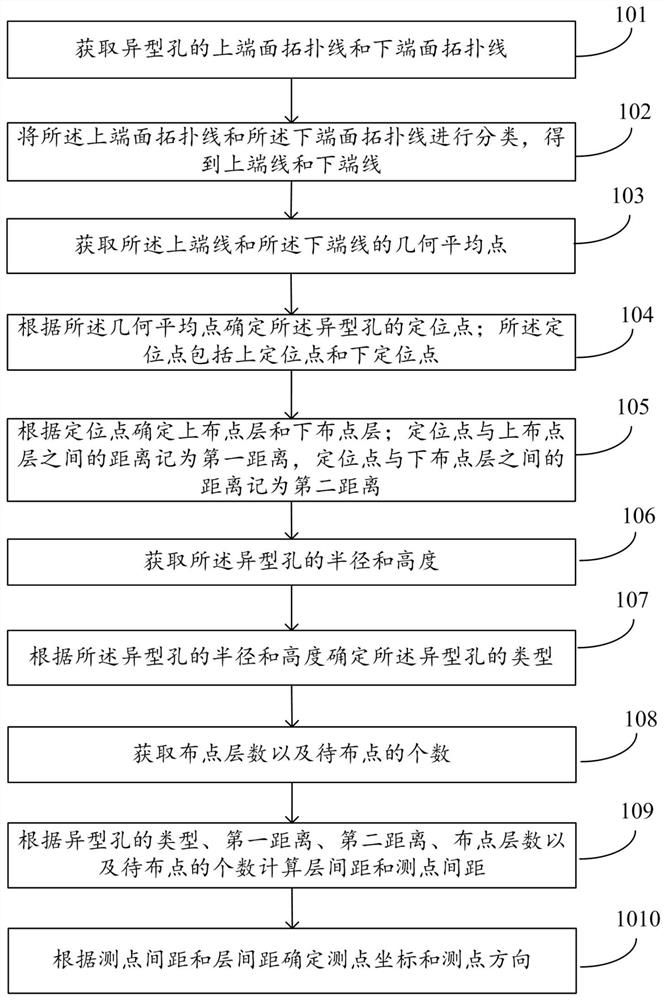

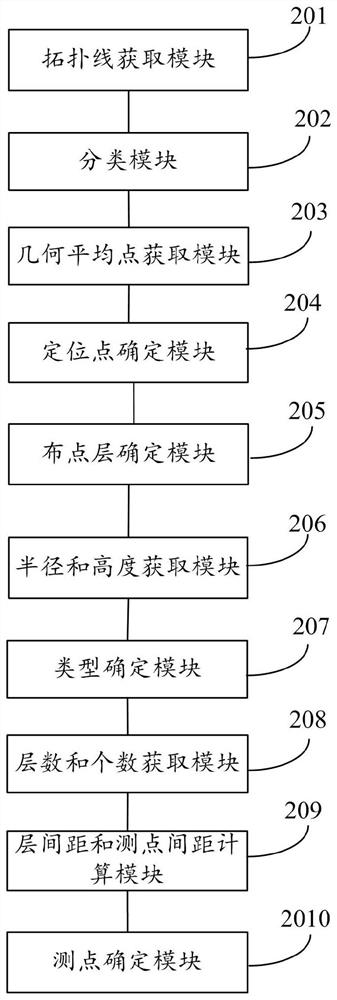

[0084] Step 1: Analysis of topological lines on the surface of special-shaped holes

[0085] (1) Classification of topological lines on the surface of special-shaped holes

[0086] The topological line classification of special-shaped holes is to separate the topological lines of the upper and lower end faces. First set a parity standard quantity k, and then traverse all topological lines. According to the characteristic that only the hole axis can have a straight line, add 1 to k when traversing to a straight line, otherwise judge the parity of k, and divide the topological line according to the parity of k They are stored in the upper and lower end line containers (ListUp, ListDown) respectively, and finally the upper and lower end lines are stored separately.

[0087] (2) Calculation of positioning points on the end face of special-shaped holes

[0088] The anchor point of the end face of the shaped hole is the closest point between the end face and the center of the hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com