A method for automatic detection of truck brake beam pillar faults

A technology for automatic detection and braking of beams, applied in braking safety systems, instruments, calculations, etc., can solve the problems of missed detection and wrong detection of brake beam pillar faults, and avoid easy missed detection, avoid wrong detection, and identify The effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

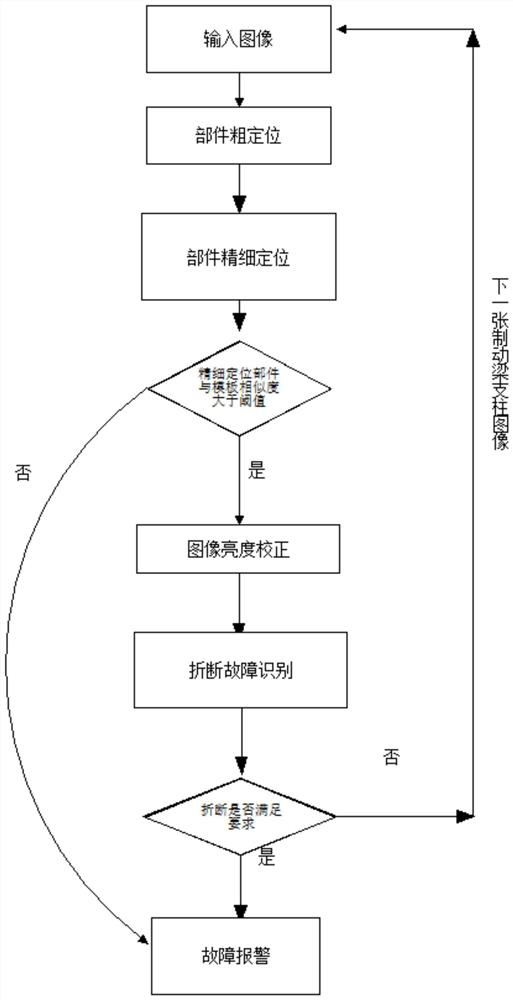

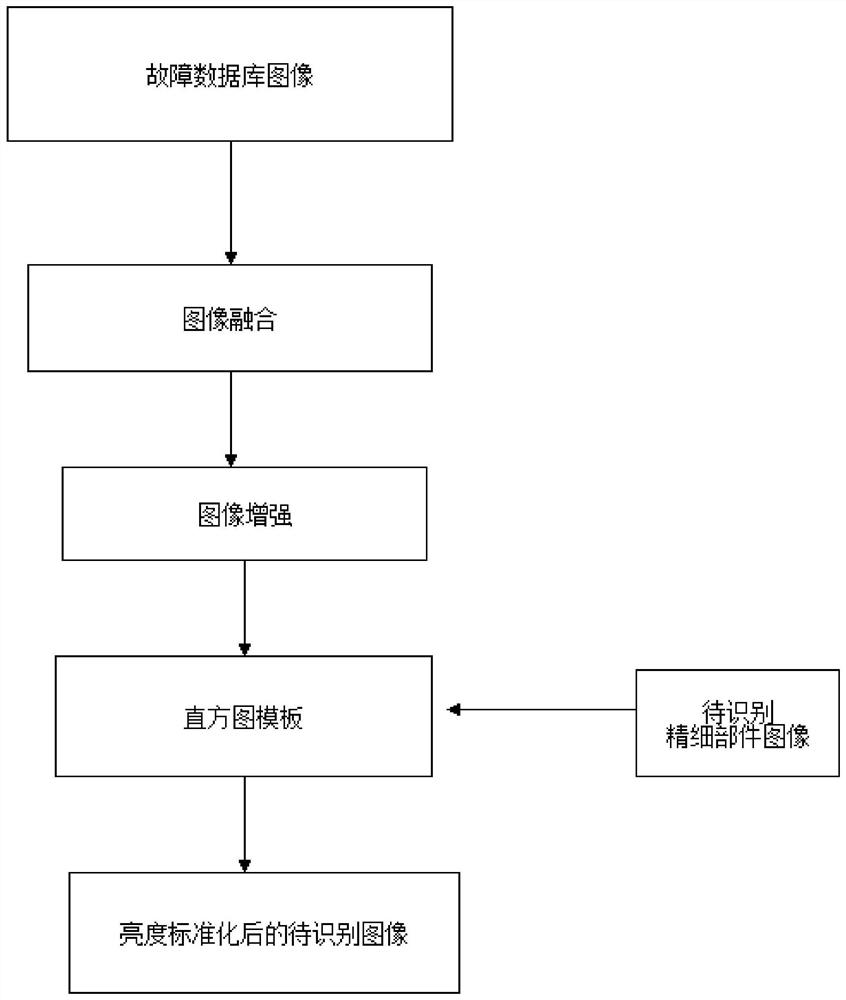

[0023] DETAILED DESCRIPTION One: Combination Figure 1 to 3 This embodiment is described. The method of automatic detection method according to the truck brake beam of the present embodiment, the method specifically includes the steps of:

[0024] Step 1, get the original image containing the brake beam pillar member;

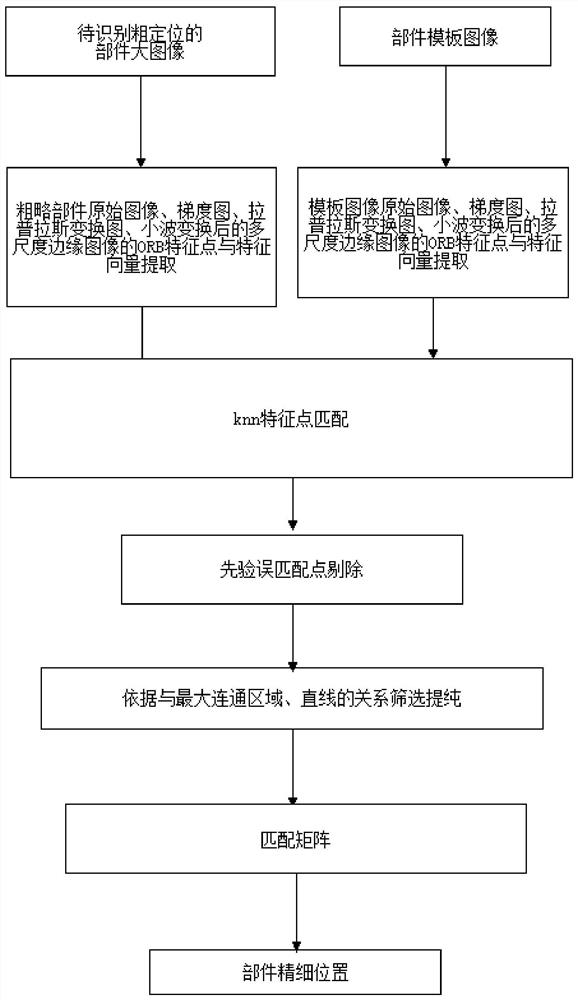

[0025] Step 2, gradient transformation, Laplas transform, and wavelet transform respectively, obtain the original image after the gradient transformation, the original image after the Laplas transform, and the original image after wavelet transform;

[0026] Extract the original image, the original image after the gradient transformation, the original image after Lapus transform, the ORB feature point and feature vector of the original image after wavelet transform, the extracted ORB feature points as the first group of ORB features point;

[0027] Other components of the non-braking beam strut portion easily cause interference to the brake beam struts, and the pres...

specific Embodiment approach 2

[0043] DETAILED DESCRIPTION OF THE INVENTION Different from the specific embodiment of the present embodiment: the specific process of the steps:

[0044] Step one by one, get a truck image;

[0045] Step 12, using the priori knowledge of the wheelbase information and the brake beam strut component position from the step of the truck image to be coarsely positioned out of the position of the brake beam strip member, the coarse positioned sub-map is included as included The original image of the brake beam strut component.

specific Embodiment approach 3

[0046] DETAILED DESCRIPTION OF THE INVENTION The third embodiment is different from that of the particular embodiment: the specific method of acquiring the truck image in the step one by one: the high-definition imaging device is built around the truck track, and the truck is acquired when the truck is passed through a HD imaging device. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com