Camera internal temperature test and internal temperature and resolving power test system and method

A technology for internal temperature and testing systems, applied in image communication, television, electrical components, etc., can solve the problems of not being able to monitor the corresponding relationship of cameras in real time, the number of points taken is small, and the corresponding relationship of cameras cannot be accurately reflected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] This embodiment will be described in detail below in conjunction with the accompanying drawings.

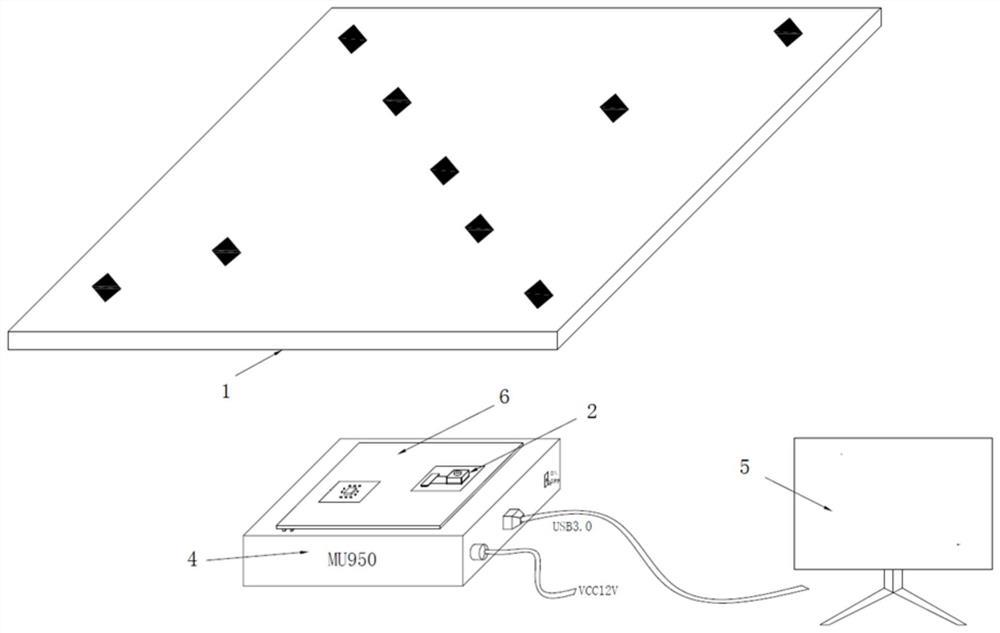

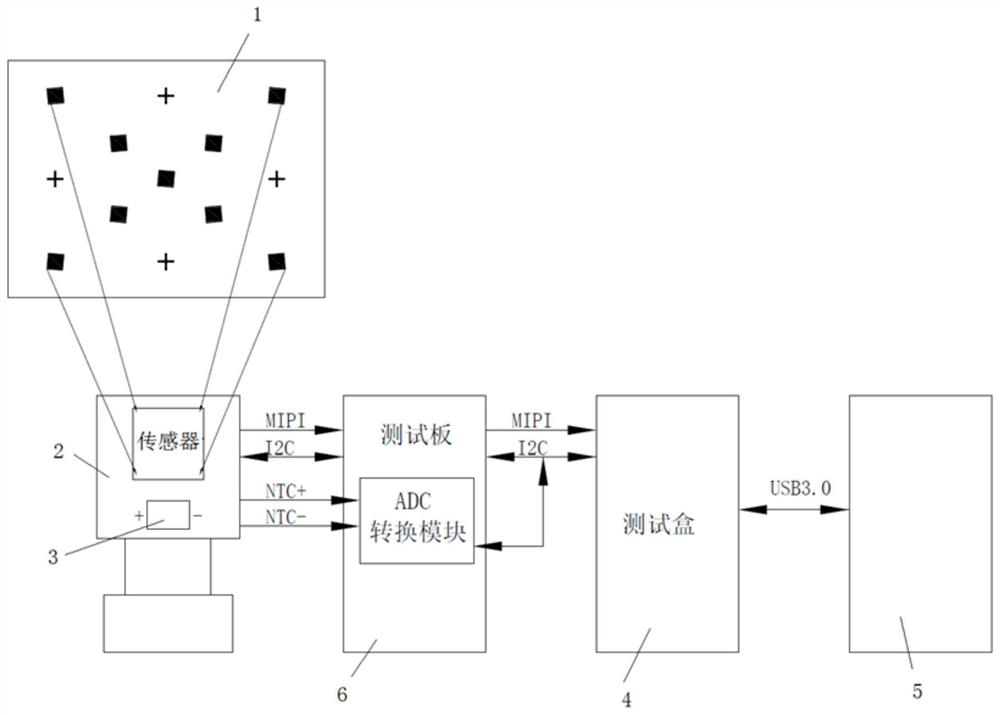

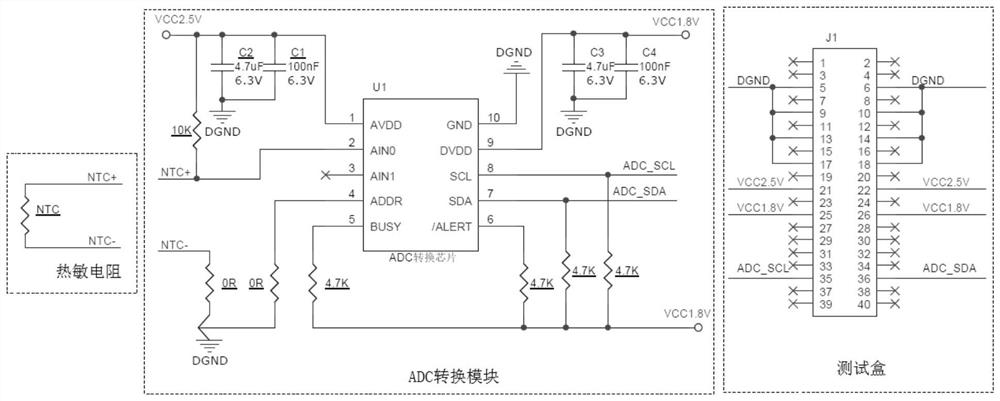

[0038] Such as Figure 1 to Figure 3 As shown, in this embodiment, a camera internal temperature and resolution test system includes a resolution test chart 1 , a thermistor 3 , a test box 4 , a test board 6 and a computer 5 . The resolution test chart 1 is installed in a test light box for providing an MTF test environment. The thermistor 3 is arranged in the camera under test 2 for real-time monitoring of the temperature inside the camera under test. Described test board 6 comprises PCB board, and is arranged on the ADC conversion module on PCB board, and described test board 6 is electrically connected with tested camera 2 and thermistor 3 respectively; Described tested camera 2 is used for shooting MTF test Environment, and the pictures taken are sent to the test box 4 through the test board 6, and the test box 4 obtains the real-time MTF resolution of the camera 2 u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com