Sample chamber for testing adsorption isotherm of material

A technology of adsorption isotherm and sample chamber, which is applied in the direction of analyzing materials and instruments, can solve problems such as large dead volume, damage to valve sealing performance, and particle flow, and achieve accurate reaction temperature, high system vacuum, and small gas resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

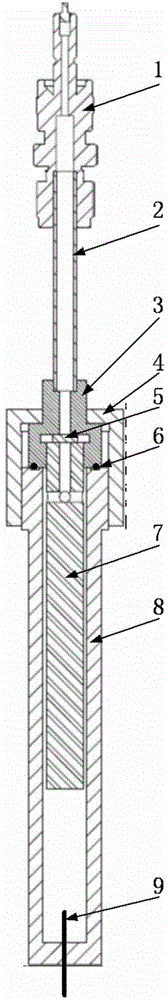

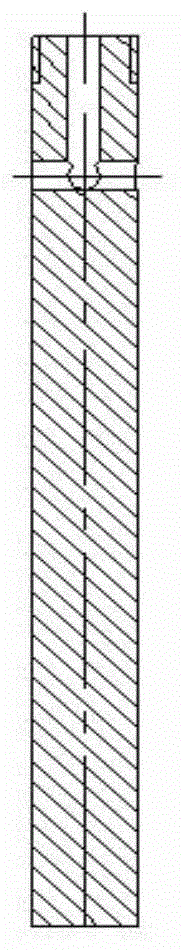

[0027] Such as figure 1 , figure 2 As shown, the sample chamber of the present invention consists of a quick connector 1, a connecting steel pipe 2, an indenter 3, an indenter nut 4, a filter screen or quartz wool 5, a gasket or a sealing ring 6, a four-way air pipe 7, a sample tube 8, a measuring Thermocouple 9 constitutes. Among them, there is an automatic closing device on the top of the quick connector 1 to prevent air from entering the sample chamber when it is disassembled from the test system; the indenter nut 4 is set on the indenter 3, and one end of the indenter 3 is welded to the connecting steel pipe 2, Then connect with the quick connector 1; there is a threaded hole in the middle of the other end of the pressure head 3, put a filter screen or quartz wool 5 in the threaded hole, and then connect the four-ventilation pipe 7 to the pressure head 3 through threads, while ensuring that the four-ventilation pipe 7. It can squeeze the filter screen or quartz wool 5 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com