Production method for pressed components, press molding device, and metal plate for press molding

A manufacturing method and technology of stamping forming, applied in the field of stamping parts manufacturing, can solve the problems of limited application range of stamping forming and large cross-section changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

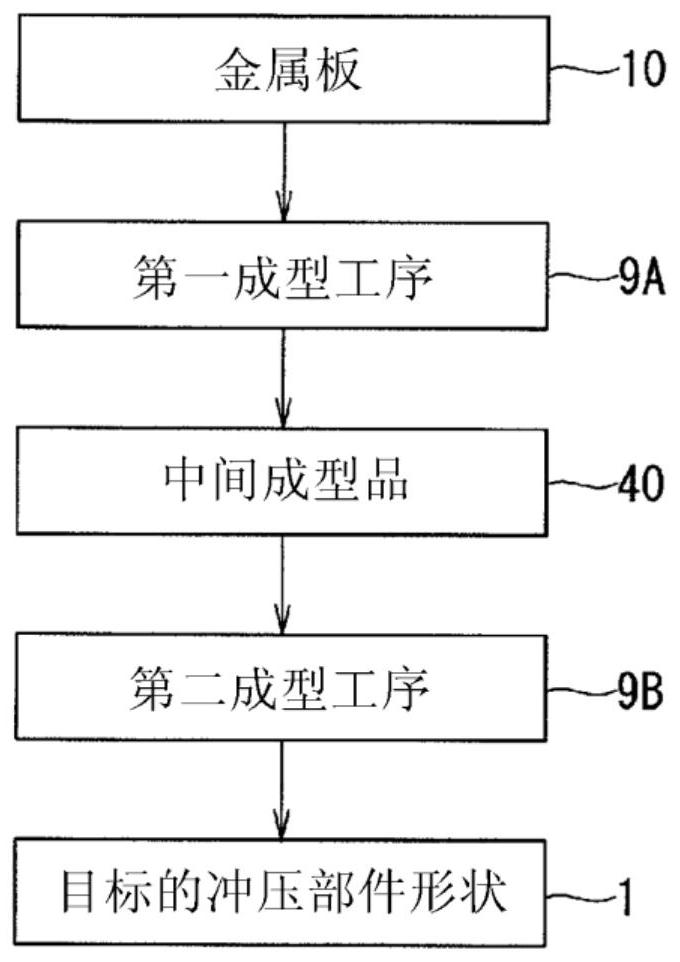

Method used

Image

Examples

Embodiment

[0094] Next, examples of this embodiment will be described.

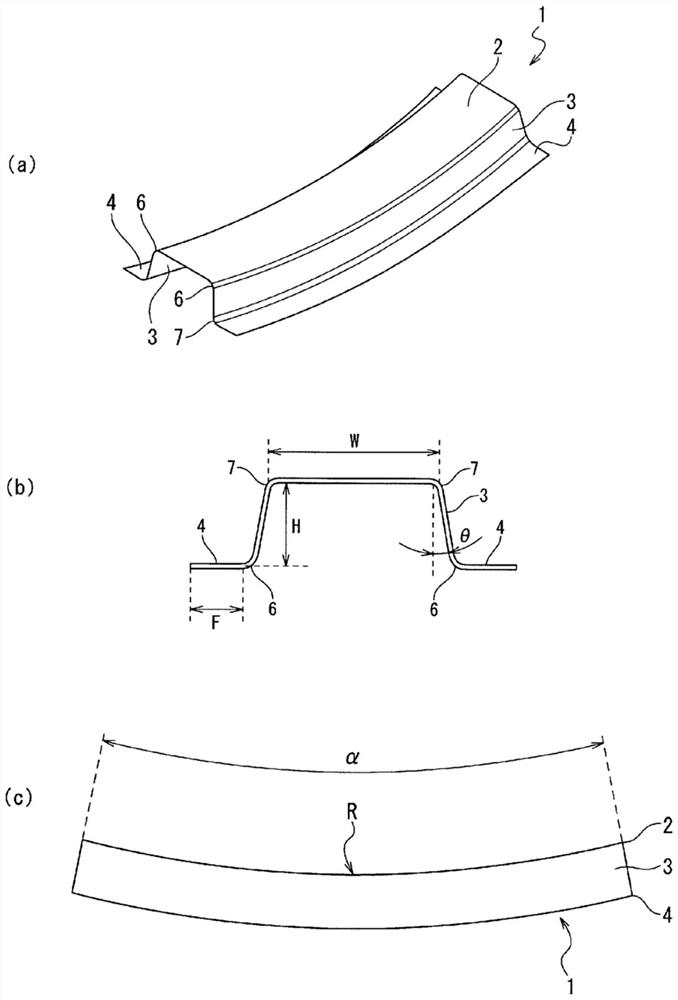

[0095] It is assumed that it is a 1180MPa grade cold-rolled steel plate (thickness 1.4mm), for such figure 1 The press forming of a member having a shape as shown will be analyzed.

[0096] In this embodiment, shape parameters defining the part shape 1 are set as follows.

[0097]

[0098] Top plate width W: 100mm

[0099] Vertical wall height H: 50mm

[0100] Vertical wall angle θ: 10 degrees

[0101] Flange length f: 30mm

[0102]

[0103] Bending angle α: 30 degrees

[0104] Roof curvature radius R: 1000mm

[0105] The metal plate 10 used for forming is set so that the length in the longitudinal direction is equal to the length in the longitudinal direction of the top plate portion 2 of the target punched part shape 1 . Specifically, the length in the longitudinal direction of the metal plate 10 was set to 523.6 mm based on the above-mentioned (1) formula. In addition, the width is set to approximatel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap