Oncomelania tail removing device

A technology for snail removal and waste removal, which is applied in the fields of crustacean processing, slaughtering, food science, etc., and can solve problems such as inaccessibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A screw tail removal device, such as Figure 1-2 As shown, it includes a support table 1, a hopper 2, a support plate 3, a tail removal mechanism 4 and a waste removal mechanism 5, a support plate 3 is provided on the left side of the top of the support table 1, and a discharge hopper 2 is provided on the right side of the upper part of the support plate 3. , the lower part of the right side of the hopper 2 is evenly opened with a discharge port 21, the top of the support table 1 is connected with a waste removal mechanism 5, and the waste removal mechanism 5 is located at the bottom of the discharge port 21, and the top right side of the support table 1 is provided with a tail removal mechanism 4 , The tail removal mechanism 4 is connected with the waste removal mechanism 5 .

[0052] When people need to remove the tails of the snails, first place the snails in the discharge hopper 2, so that the lower part of the snails falls onto the discharge port 21, and then start...

Embodiment 2

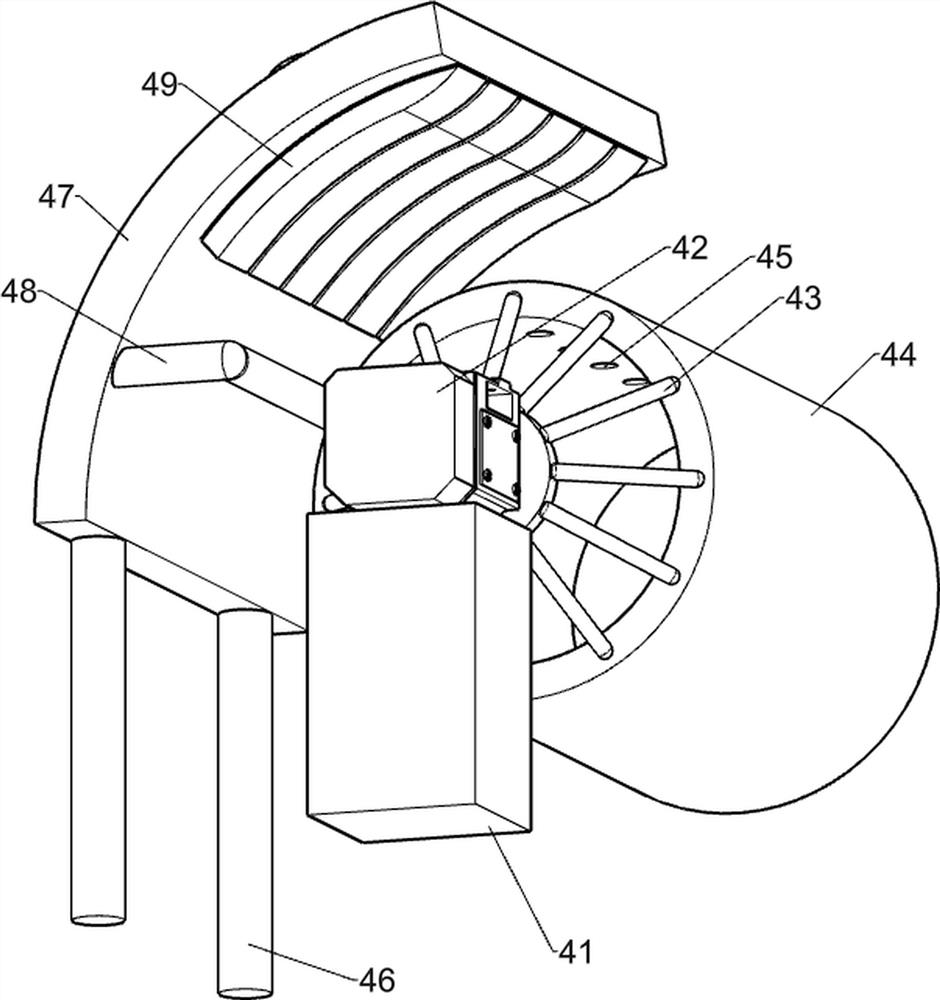

[0054] On the basis of Example 1, such as Figure 3-5 As shown, the tail removal mechanism 4 includes a support table 41, a motor 42, a connecting rod 43, a cylinder 44, a support column 46, a shed 47, a stop rod 48, an extrusion block 49, a rotating disk 410, a first support shaft 411, a guide Rod 412 and the first spring 413, support column 46 is connected with support column 46 on the right side of support table 1 top, is connected with shed 47 between support column 46 tops, is provided with retainer bar 48 on the left side of shed 47 bottom, and shed 47 top Guide rods 412 are evenly spaced slidingly connected, and the bottoms of the guide rods 412 are connected with extruding blocks 49, and the tops of the extruding blocks 49 and the shed 47 are connected with first springs 413, and the first springs 413 are all set on the guide rods. 412, a support platform 41 is provided on the top rear side of the support table 1, a motor 42 is connected to the top rear side of the sup...

Embodiment 3

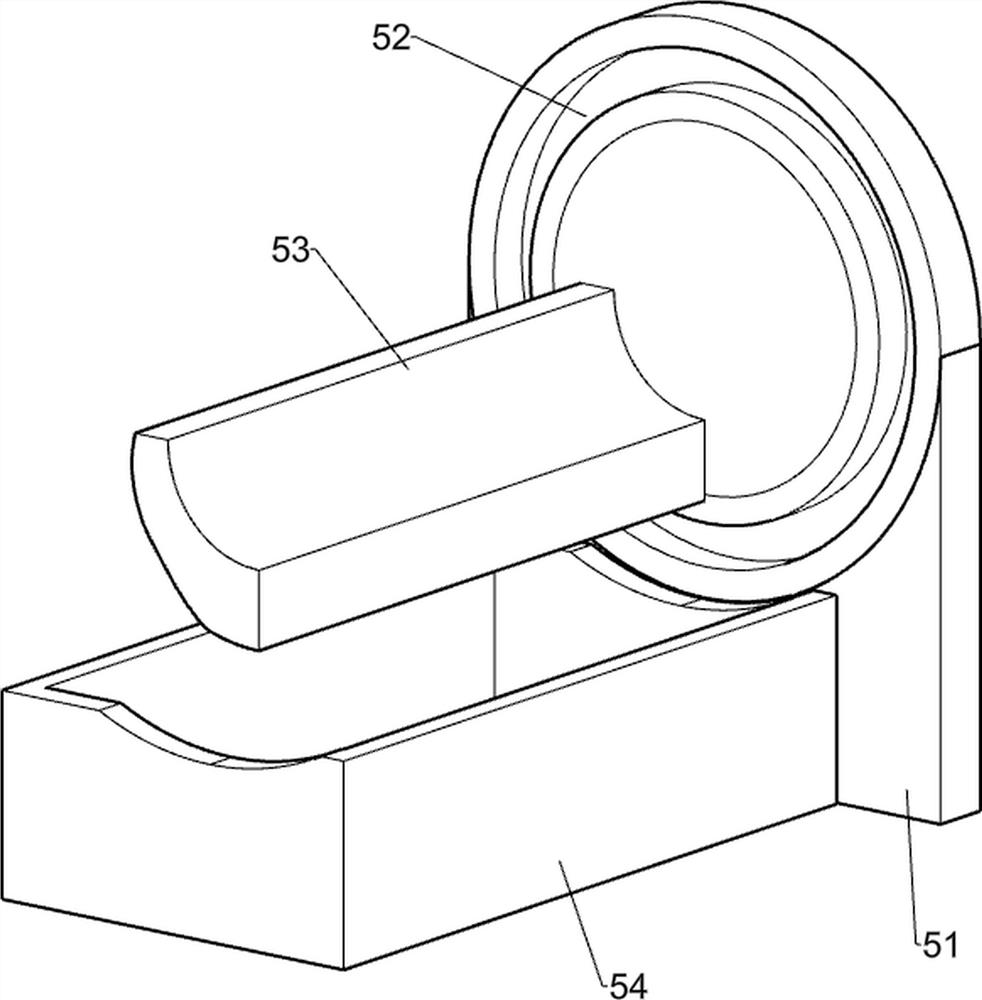

[0057] On the basis of Example 2, such as Figure 6-8 As shown, the waste removal mechanism 5 includes a support sleeve 51, an extrusion block 53 and a collection frame 54. The left side of the front part of the support table 1 is provided with a support sleeve 51, and the rear side of the top of the support sleeve 51 is provided with a guide groove 52. The upper part is connected with the guide groove 52 in a rotational manner, the upper rear side of the support sleeve 51 is connected with an extruding block 53, and the lower rear side of the support sleeve 51 is connected with a collection frame 54, and the collection frame 54 is located below the cylinder 44.

[0058] When the snail tail rotates with the cylinder 44 to contact with the extrusion block 53, the extrusion block 53 slowly squeezes the snail out of the snail tail, and the snail tail is extruded and falls into the collection frame 54. Repeat the above operations The screw tail can be taken out.

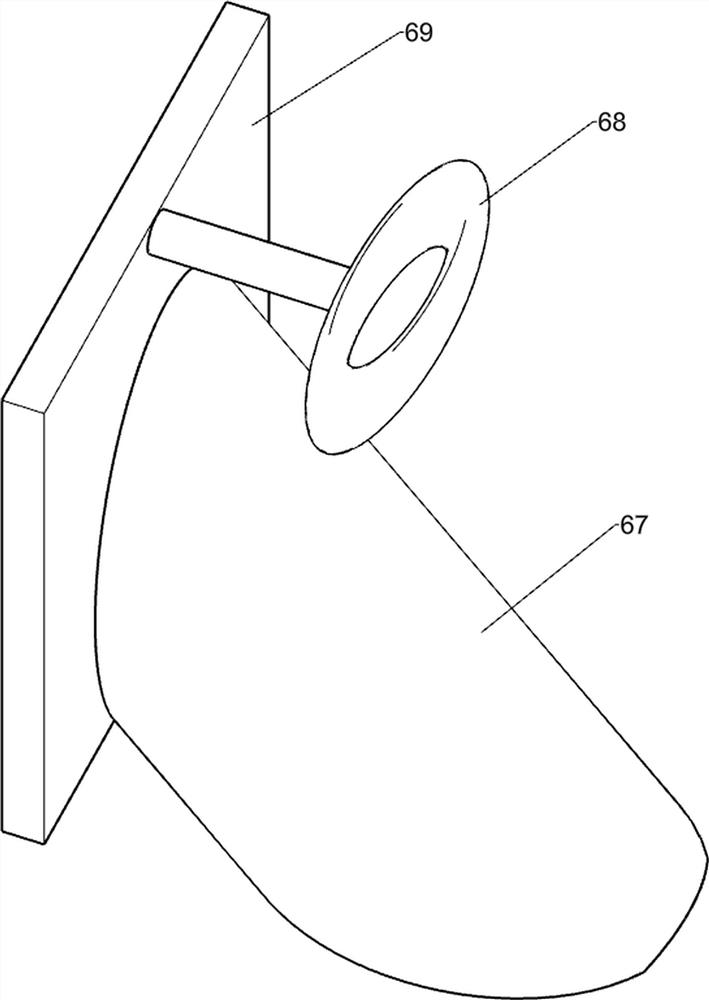

[0059] Also inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com