Belt cleaning machine for sole glue spraying assembly line

A technology of assembly line and washing machine, which is applied in the direction of shoemaking machinery, footwear, and gluing shoe parts, etc. It can solve the problems of glue falling and the bottom cannot be in direct contact with water flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] For example figure 1 -example Figure 5 Shown:

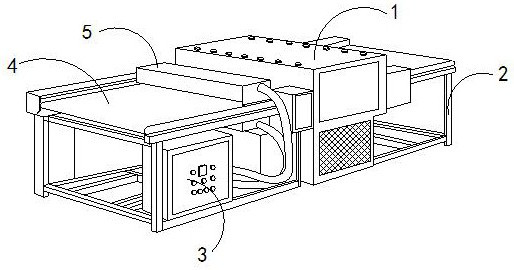

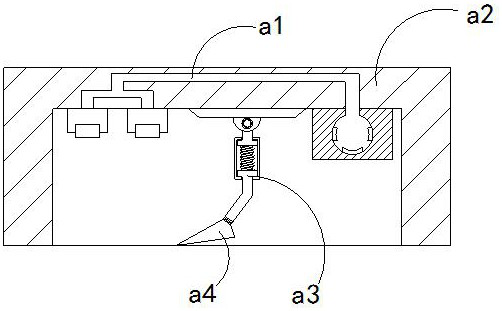

[0027] The present invention provides a shoe sole glue spraying assembly line belt cleaning machine, the structure of which includes a shield 1, a base bracket 2, a control electric box 3, a transmission belt 4, and a cleaning mechanism 5, and the shield 1 is embedded and connected with the base bracket 2, The control electrical box 3 is connected to the base bracket 2, the transmission belt 4 is engaged with the base bracket 2, and the cleaning mechanism 5 is installed on the upper end of the transmission belt 4; the cleaning mechanism 5 includes a water spray chamber a1 , frame a2, connecting rod a3, plastic blade a4, the water spray chamber a1 and the frame a2 are an integrated structure, the connecting rod a3 is connected with the inner wall top of the frame a2, and the plastic blade a4 is installed on the connecting rod a3 bottom position.

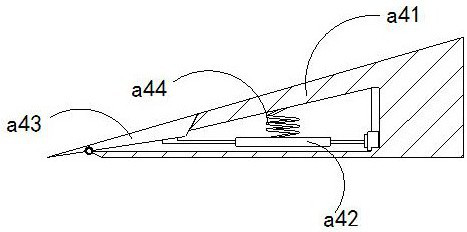

[0028] Wherein, the plastic blade a4 includes a frame body a41, a linkage...

Embodiment 2

[0034] For example Image 6 -example Figure 8 Shown:

[0035] Wherein, the water permeable port c1 includes a lower plate c11, a housing c12, a guide frame c13, an elastic strip c14, and a sliding rod c15, the lower plate c11 is in clearance fit with the housing c12, and the guide frame c13 and the housing c12 are an integrated structure , the elastic bar c14 is embedded between the sliding rod c15 and the pedestal c13, one end of the sliding rod c15 is in clearance fit with the pedestal c13, and the other end of the sliding rod c15 is connected to the bottom of the sliding plate c11, through The thrust generated by the water flow on the lower plate c11 can make the lower plate c11 push the sliding rod c15 to slide and shrink along the guide frame c13, so that the water can be discharged into the lower part of the shell c12 through the gap between the lower plate c11 and the shell c12 Location.

[0036] Wherein, the lower plate c11 includes a lower pressing plate d1, a dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com