Injection spray mop

A jet mop technology, applied in the field of injection jet mops, can solve the problems of large volume and cost, easy spillage, time-consuming and other problems without cleaning solution dispensing bottles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The injection spray mop is described and depicted by the specification and drawings. As used herein, the term "jet mop" refers to a cleaning device that has the ability to deliver liquid to aid in the cleaning process of the device. The term "injection" refers to a combination of two or more liquids, such as introducing one or more liquids into another liquid or liquids.

[0026] For a general understanding of the invention, refer to the accompanying drawings. In the figures, the same reference numerals are used to denote the same elements throughout.

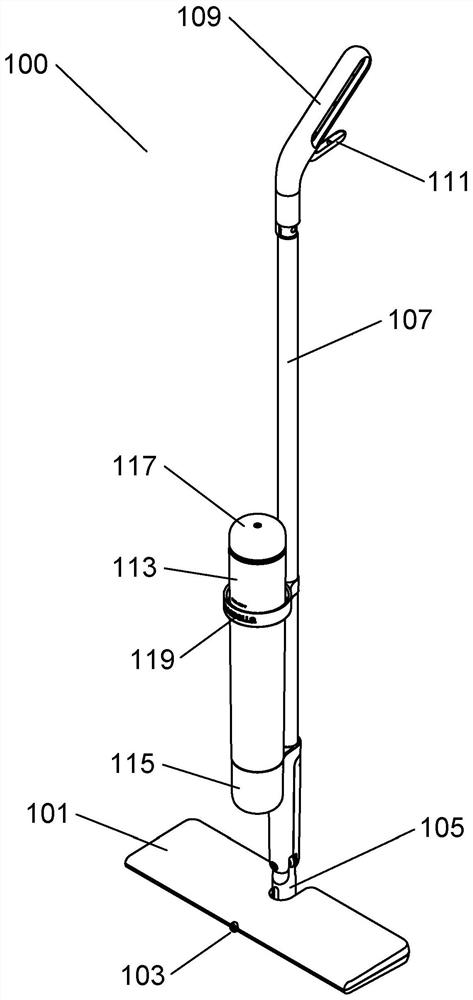

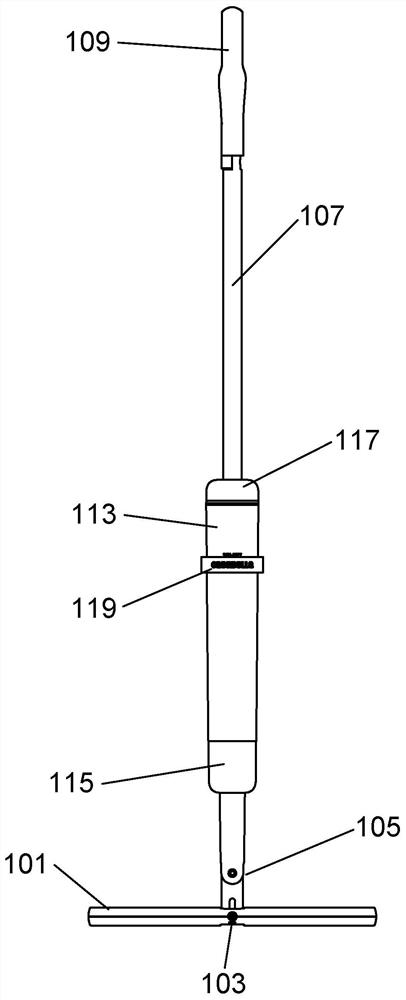

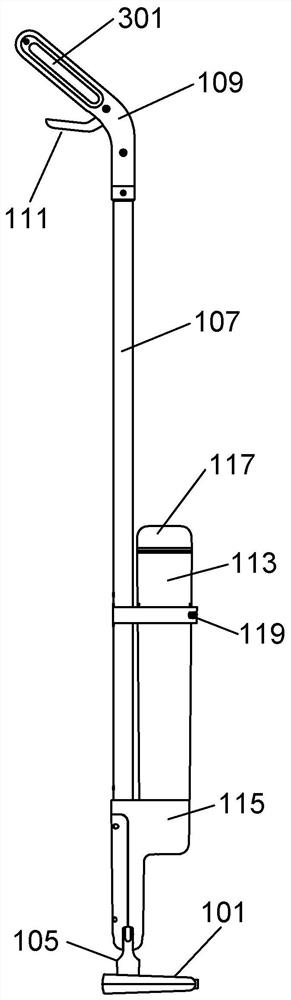

[0027] refer to figure 1 , shows a perspective view of the injection spray mop 100 . The mop head 101 is depicted as comprising an upper half and a lower half. While the mop head 101 may have separate upper and lower halves joined together, in some embodiments of the invention, the mop head 101 is made from a single piece. For the purposes of this description, such a one-piece implementation will still have an upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com