Decoration device for brushing texture paint on wooden board

A technology of wood boards and textures, which is applied in the field of wood board brush texture paint devices for decoration appliances, which can solve the problems of difficulty in controlling the paint brushing force, time-consuming and labor-intensive problems, and achieve the effect of speeding up the drying speed, uniform painting, and consistent force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

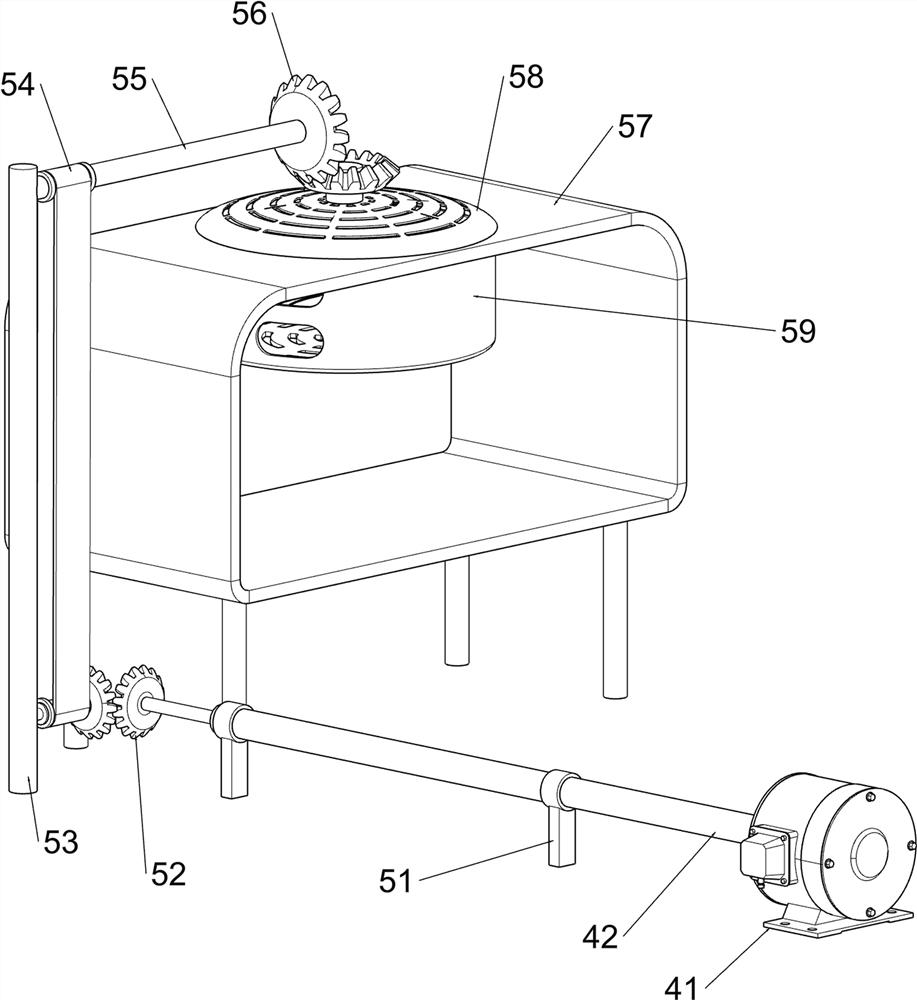

[0062] A kind of device for decorating utensils board brush texture paint, such as figure 1 As shown, it includes a fixed plate 1, a first fixed bracket 2, a workbench 3, a paint brushing mechanism 4 and an air-drying mechanism 5. The top of the fixed plate 1 is connected with a plurality of first fixed brackets 2, and between the tops of the first fixed brackets 2 Be connected with workbench 3, be connected with painting mechanism 4 between the front and rear sides of fixed plate 1 right, be connected with air-drying mechanism 5 between fixed plate 1 left, front and rear sides, air-drying mechanism 5 is connected with painting mechanism 4.

[0063] When people need to paint the texture of the plank, the plank is first placed on the workbench 3, then the paint is poured on the parts of the painting mechanism 4, and then the painting mechanism 4 is started to drive the parts of the painting mechanism 4 to the plank. Carry out painting, along with people push plank, plank is fin...

Embodiment 2

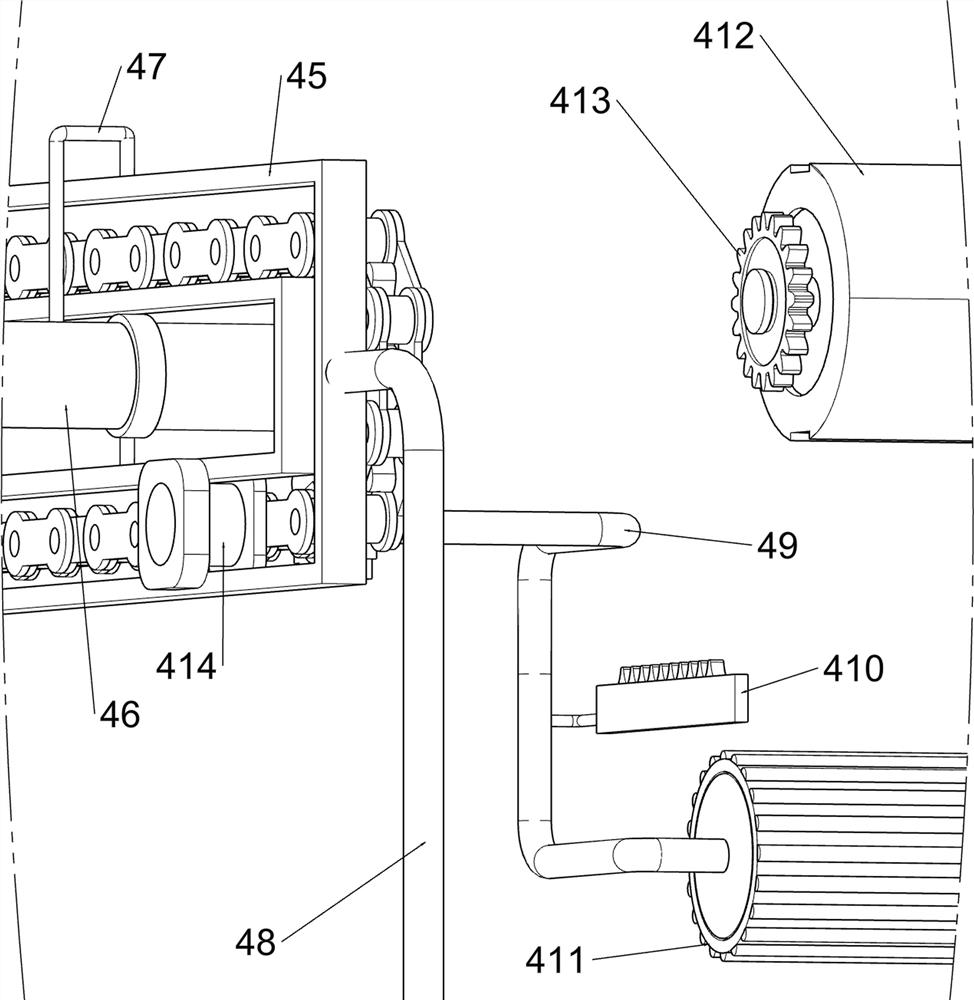

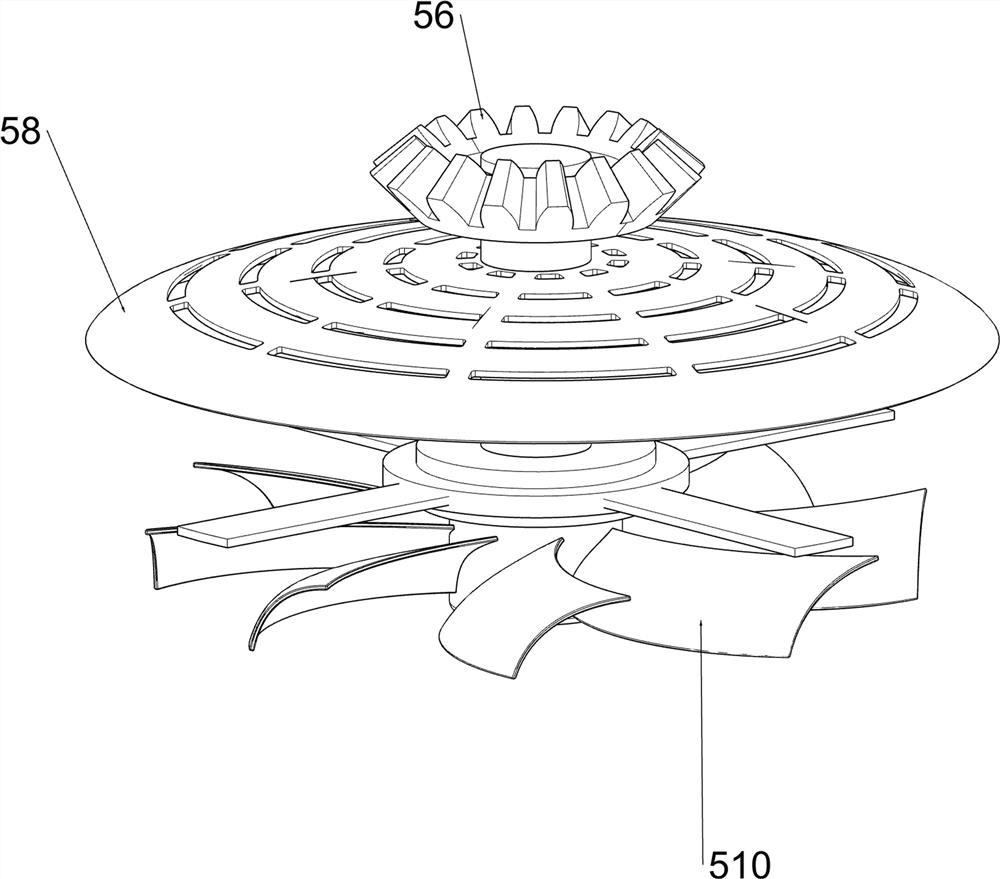

[0065] On the basis of Example 1, such as Figure 2-6 As shown, the painting mechanism 4 includes a motor 41, a first connecting shaft 42, a first conveyor belt 43, a sprocket assembly 44, a square frame 45, a first fixed column 46, a first connecting rod 47, a second fixed column 48, The second connecting rod 49, the rack 410, the roller brush 411, the paint box shell 412, the full gear 413, the circular slider 414 and the circular paint storage column 415, the front and rear sides of the right part of the fixed plate 1 are connected with the second fixed Column 48, square frame 45 is connected between the second fixed column 48, the first fixed column 46 is connected with fixed plate 1 right side rear, the first fixed column 46 is positioned at square frame 45 right sides, the first fixed column 46 front and back two The left part of the side is connected with a rotating shaft in a rotating manner, and a sprocket assembly 44 is connected between the rotating shafts. The spro...

Embodiment 3

[0070] On the basis of Example 2, such as Figure 7-8 As shown, it also includes a plank conveying mechanism 6, and the plank conveying mechanism 6 includes a second fixed bracket 61, a third connecting rod 62, a pulley 63, a first pull plate 64 and a connecting plate 65, and the front and rear sides of the fixed plate 1 are Both are connected with two second fixed brackets 61, the upper part of the second fixed bracket 61 is connected with a third connecting rod 62, and the third connecting rod 62 is connected with a pulley 63 in a rotating manner. A connecting plate 65 is connected, and the upper side of the connecting plate 65 is provided with card slots, and the first hand pull plate 64 is clamped between the card slots.

[0071] When people need to paint the plank, the first hand pull plate 64 is moved to the rear side and pulled out, and then the first hand pull plate 64 is inserted into the draw-in groove on the upper side, so that the first hand pull plate 64 and the p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap