Multifunctional kitchen waste barrel cleaning system

A cleaning system and technology for kitchen waste, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problem of not considering the perishable odor of kitchen waste, mixed solid and liquid, belonging to other garbage, and can not meet the needs of the city. Residents' household kitchen waste treatment needs and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

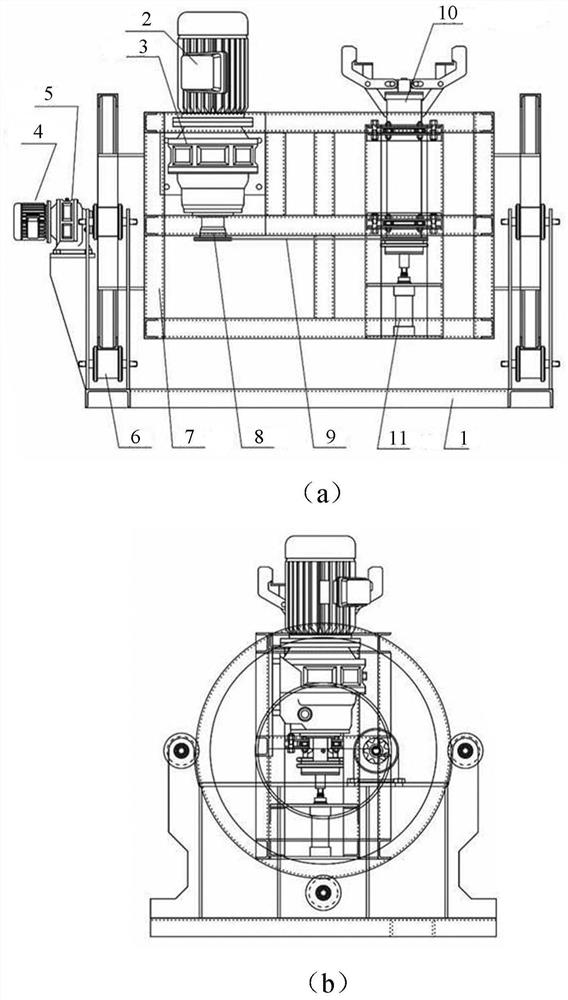

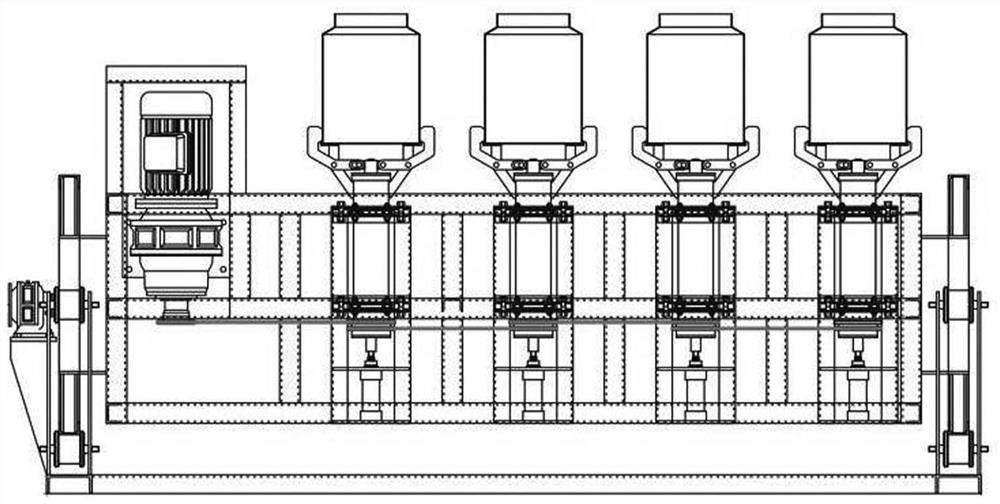

[0028] Hereinafter, the kitchen waste multi-functional barrel-type cleaning system of the present invention will be described in detail with reference to the accompanying drawings and exemplary embodiments.

[0029] In an exemplary embodiment of the present invention, the kitchen waste multifunctional bucket cleaning system may include: a machine base, a rotating support, a first driving unit, at least one mechanical gripper and a second driving unit.

[0030] The machine base can be set on the workbench, for example, on the ground outdoors, on the bottom surface in the workshop, and the like. The frame is a support base, and its shape can be determined according to the actual situation, as long as it can support and fix other structures. The work surface can be parallel to the horizontal plane.

[0031] Both the rotating bracket and the first driving unit can be arranged on the machine base, and both can be connected with the machine base. The first driving unit may include...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com