Treatment for solidifying slag into blocks after iron ore metallurgy

A metallurgical and slag technology, applied in the field of iron ore metallurgy after slag solidification into blocks, can solve the problems of air and land pollution, groundwater pollution, high temperature slag transportation and discharge hazards, etc., and achieve the effect of saving resources and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

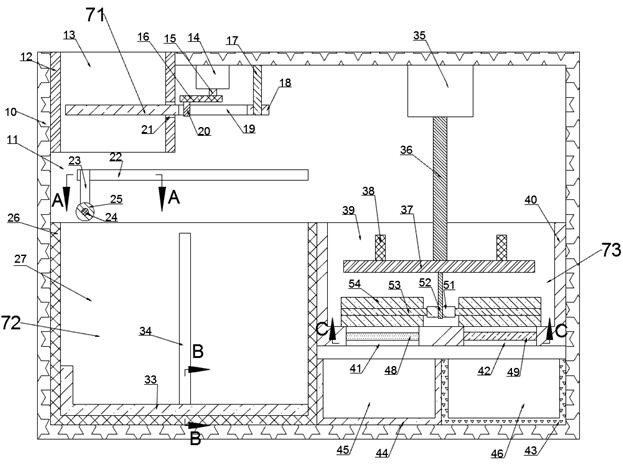

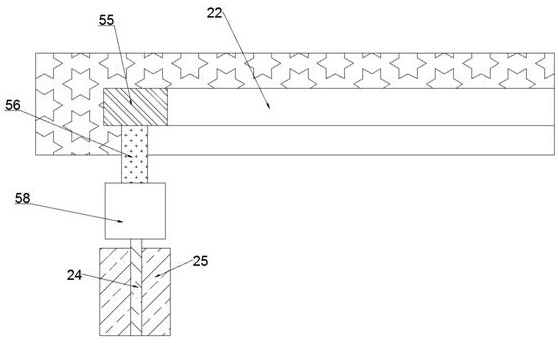

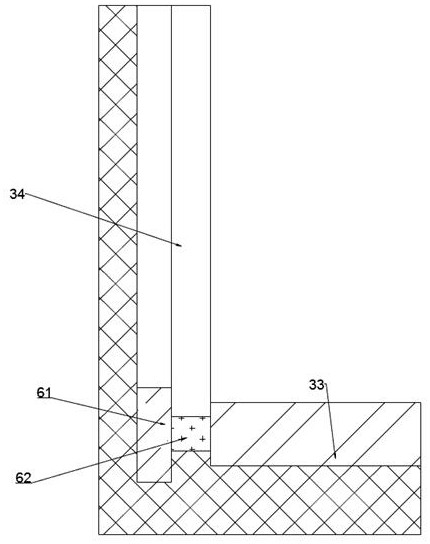

[0018] Combine below Figure 1-4 The present invention will be described in detail, in which, for the convenience of description, the directions mentioned below are now specified as follows: figure 1 The vertical, horizontal, front, and rear directions of the projection relationship are the same.

[0019] Attached Figure 1-4 The iron ore metallurgical slag is solidified into lump processing, including a shell 10, the shell 10 is provided with a closed shell cavity 11, the shell cavity 11 is provided with an inlet interrupting device 71, the inlet The interrupting device 71 includes a pouring port 12 fixedly arranged on the inner wall of the left side of the housing cavity 11, the pouring port 12 penetrates the upper side wall of the housing cavity 11, and the pouring port 12 is A pouring cavity 13 is provided, the pouring cavity 13 opens up and down, and the right side of the pouring cavity 13 is provided with a swinging cavity 21, and the swinging cavity 21 penetrates the righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com