Open deck molding equipment with built-in transfer device

A technology of forming equipment and transfer device, which is applied in metal processing and other directions, can solve the problems of single fixed structure of cutting device, inconvenient adjustment and replacement, occupying a large site space, etc., and achieves improvement of structural firmness and stability, simple structure, horizontal The effect of reducing space occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

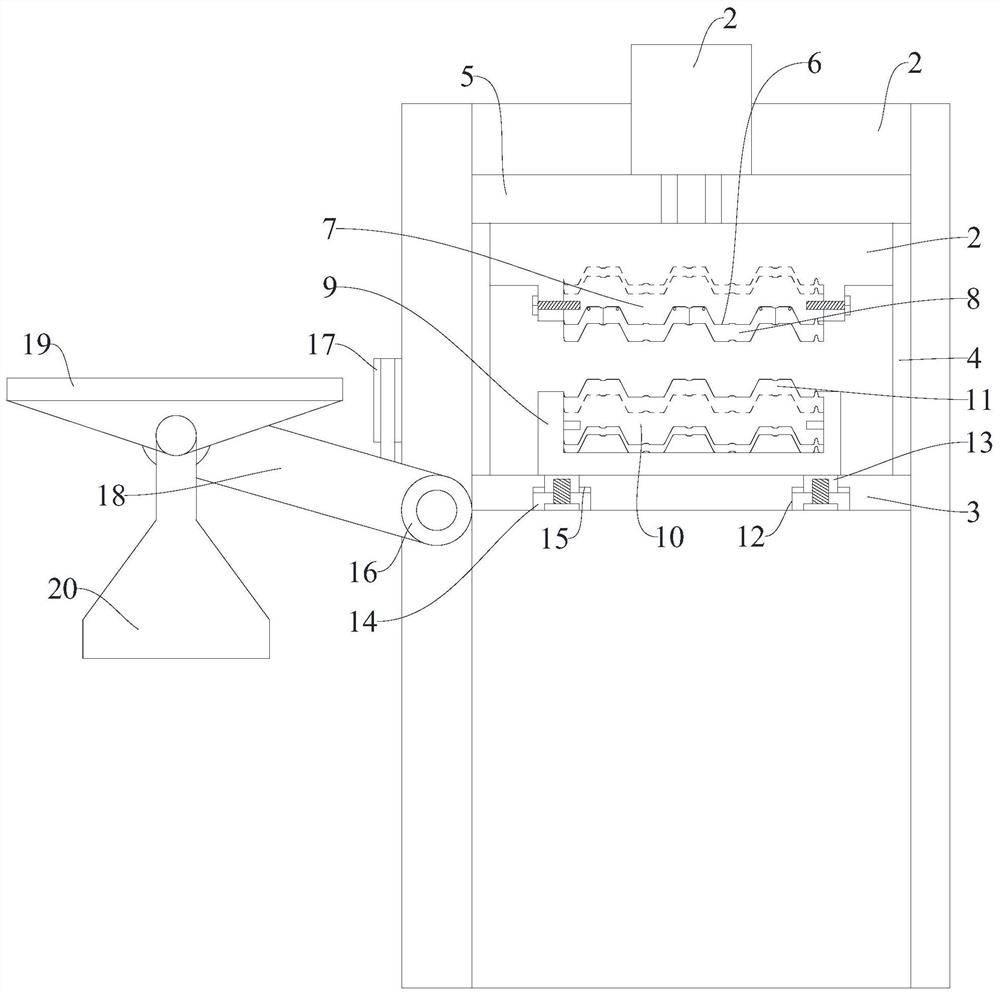

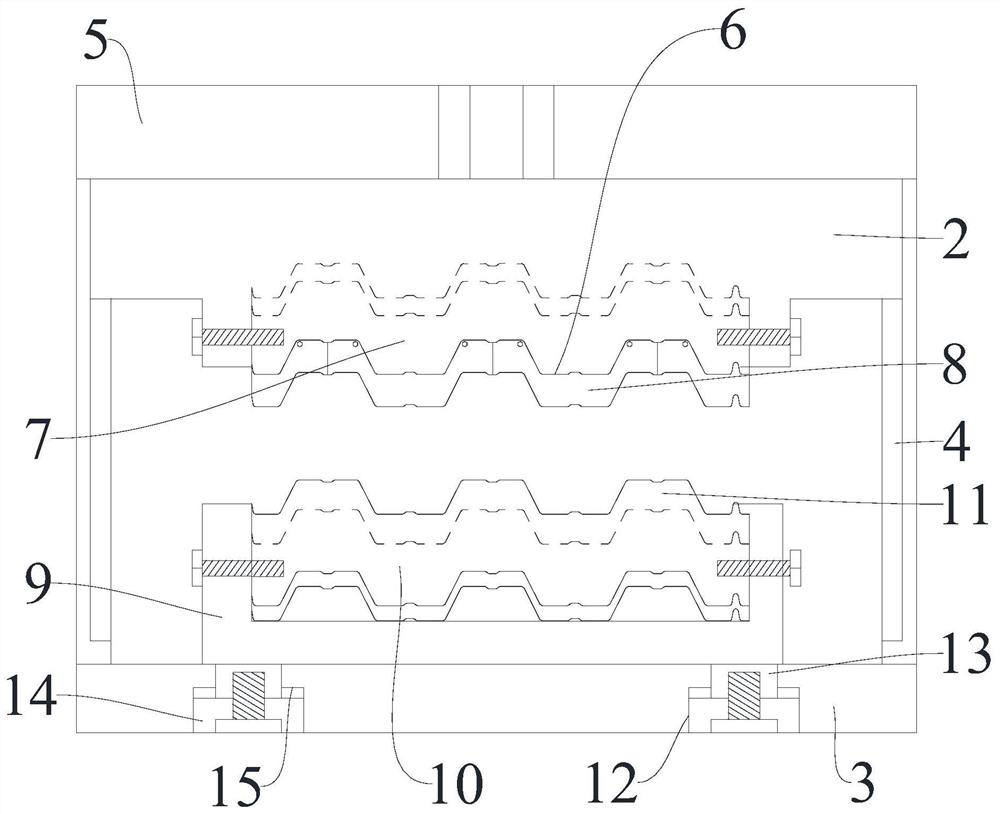

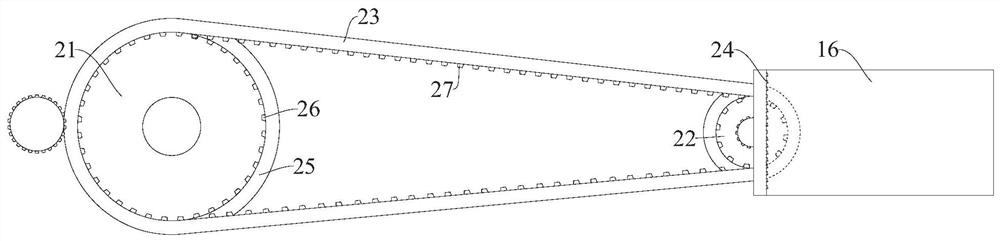

[0026] Embodiment: When the main body 1 of the floor deck forming machine is running, the side turning linkage mechanism is turned over synchronously, and the speed is adjusted by changing the transmission wheel ratio of the turning linkage mechanism as required, as long as it is adjusted according to the length of the floor deck.

[0027] The floor deck forming machine body 1 is used for producing and processing YX51-246-720-750-760-780 floor decks.

[0028] Further, in order to improve cutting stability and facilitate quick switching and adjustment, the combined cutting head includes a top fixing seat 7 fixed and installed in the bottom mounting groove 6 by a transverse bolt and a split cutting head fixed at the lower end of the top fixing seat 7 8. The combined bottom support platform includes an external installation pedestal 9 and a built-in support pedestal 10. The upper surface of the built-in support pedestal 10 is provided with an overhead cutting transition groove 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com