A double-stage reinforced soil abutment with densely arranged reinforcements and its construction method

A technology of reinforced soil and abutments, applied in the direction of bridges, artificial islands, bridge construction, etc., can solve the problems of large distance between the pedestal and the wall, increased land cost, limited bearing capacity, etc., to achieve low cost, save construction site, The effect of improving the carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

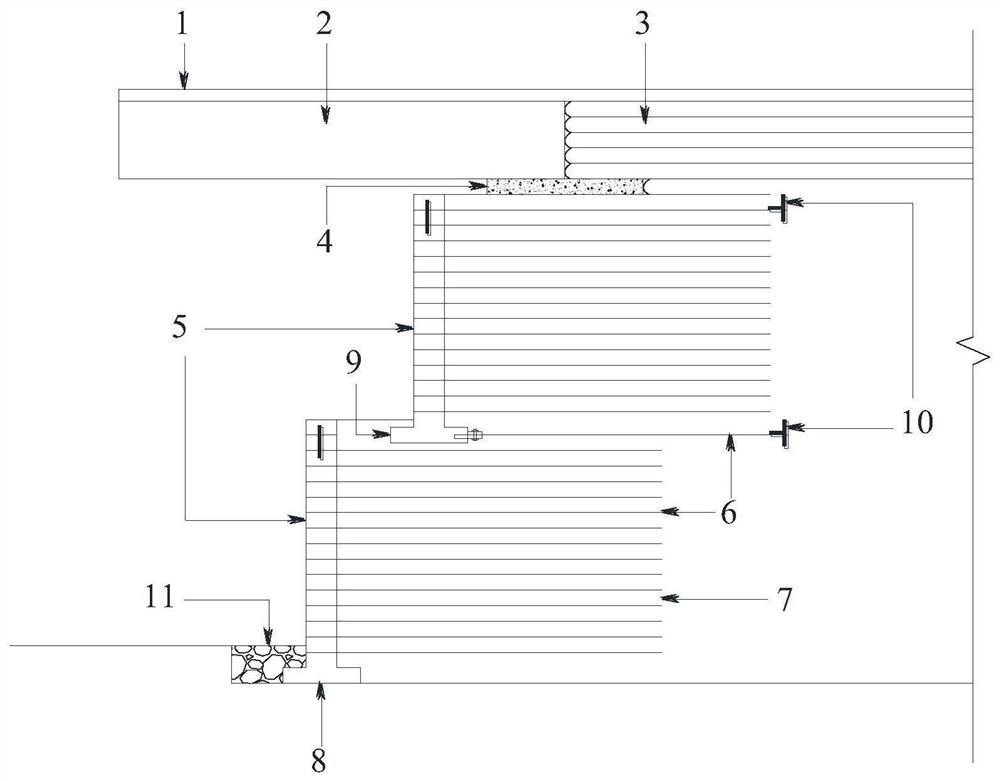

[0038] Such as figure 1 A two-stage reinforced soil abutment with closely arranged reinforcement materials is shown, mainly including pavement structure 1, bridge superstructure 2, closely spaced reinforced soil approach road 3, pedestal 4, upper reinforced soil Abutment system, lower reinforced soil abutment system and gravel protection body 11.

[0039] The pedestal 4 is a reinforced concrete slab structure, which directly supports the bridge superstructure 2 and the closely spaced reinforced soil approaches 3, and evenly distributes the loads of the bridge superstructure 2 and the closely spaced reinforced soil approaches 3 on the upper reinforced soil abutment The top of the bridge is conducive to keeping the bridge superstructure 2 and the closely spaced reinforced soil approach road 3 smooth. Close-spaced reinforced soil approach road 3 adopts a back-wrapped reinforced soil structure with a spacing of 0.2m. This type of reinforced soil approach road has relatively high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com