Polishing bending-preventing jig

A technology of anti-bending and jigs, which is applied in the direction of grinding/polishing equipment, manufacturing tools, grinding devices, etc., and can solve problems such as extrusion light leakage, low apparent yield, and polishing that cannot be mass-produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below, the technical solution of the present invention will be described in detail through specific examples.

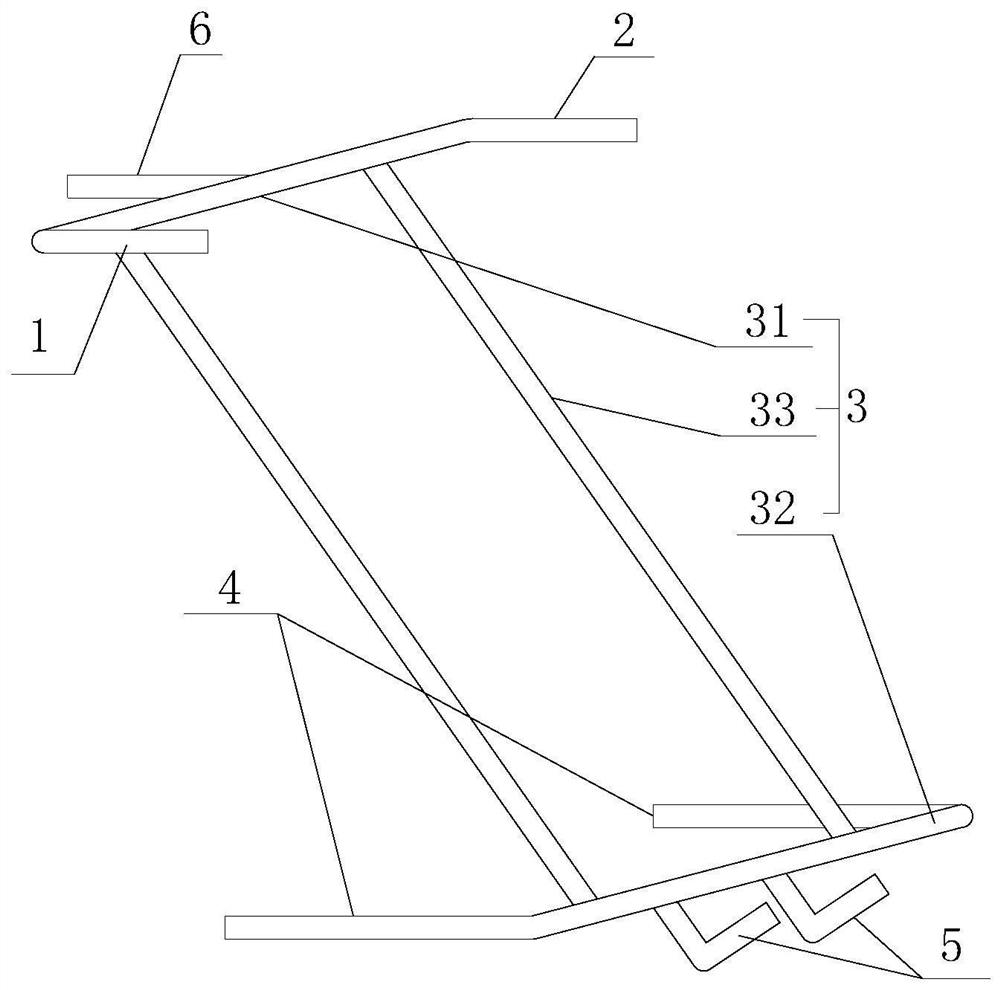

[0015] Such as figure 1 as shown, figure 1 Schematic diagram of the structure of a polishing anti-bending jig proposed for the invention.

[0016] refer to figure 1 , a polishing anti-bending fixture proposed by the present invention, comprising: a bracket, the bracket has a support surface arranged obliquely for supporting the workpiece, and is arranged below the support surface for limiting the bottom of the workpiece The limiting surface, and the first limiting edge 1 and the second limiting edge 2 which are oppositely arranged on both sides of the supporting surface for limiting both sides of the workpiece.

[0017] When in use, the glass to be polished is placed on the support surface of the jig, and the bottom of the glass is supported by the limiting surface, and the two sides of the glass are limited by the first limiting edge 1 and the second limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com