SCARA robot

A robot and base technology, applied in the field of robotics, can solve problems such as large forearm size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

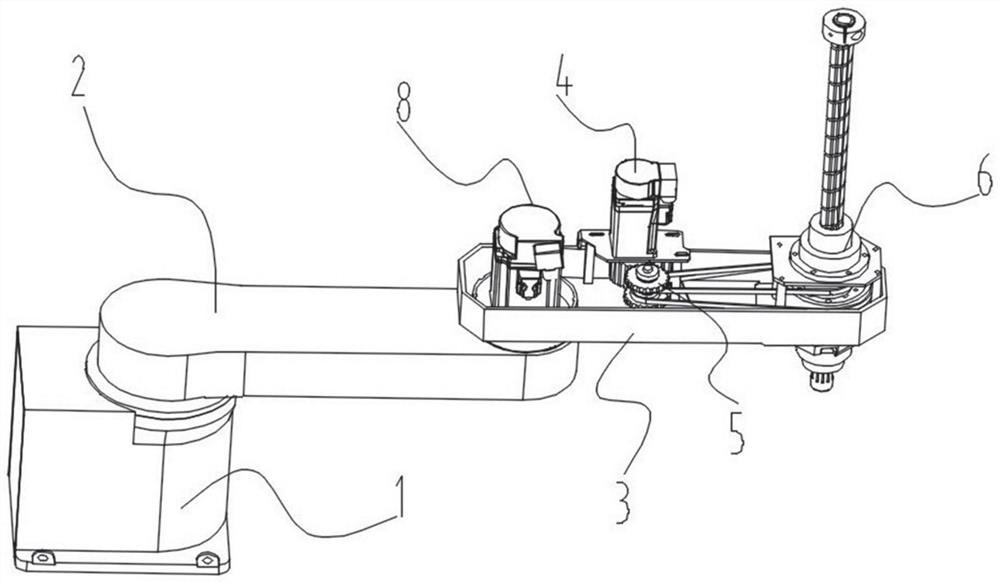

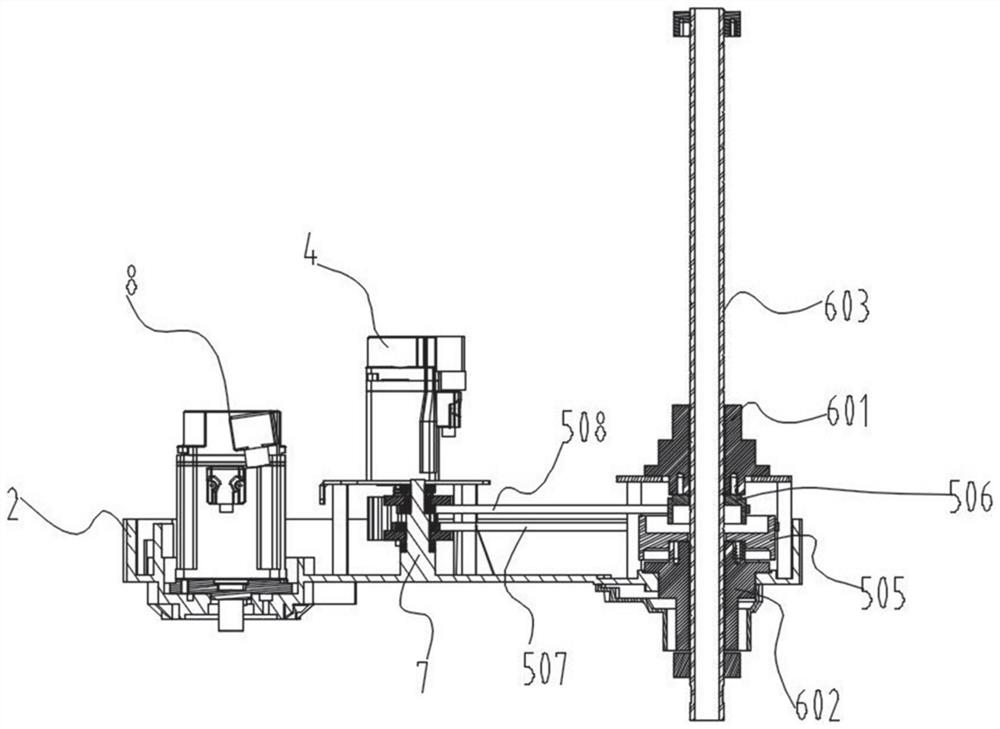

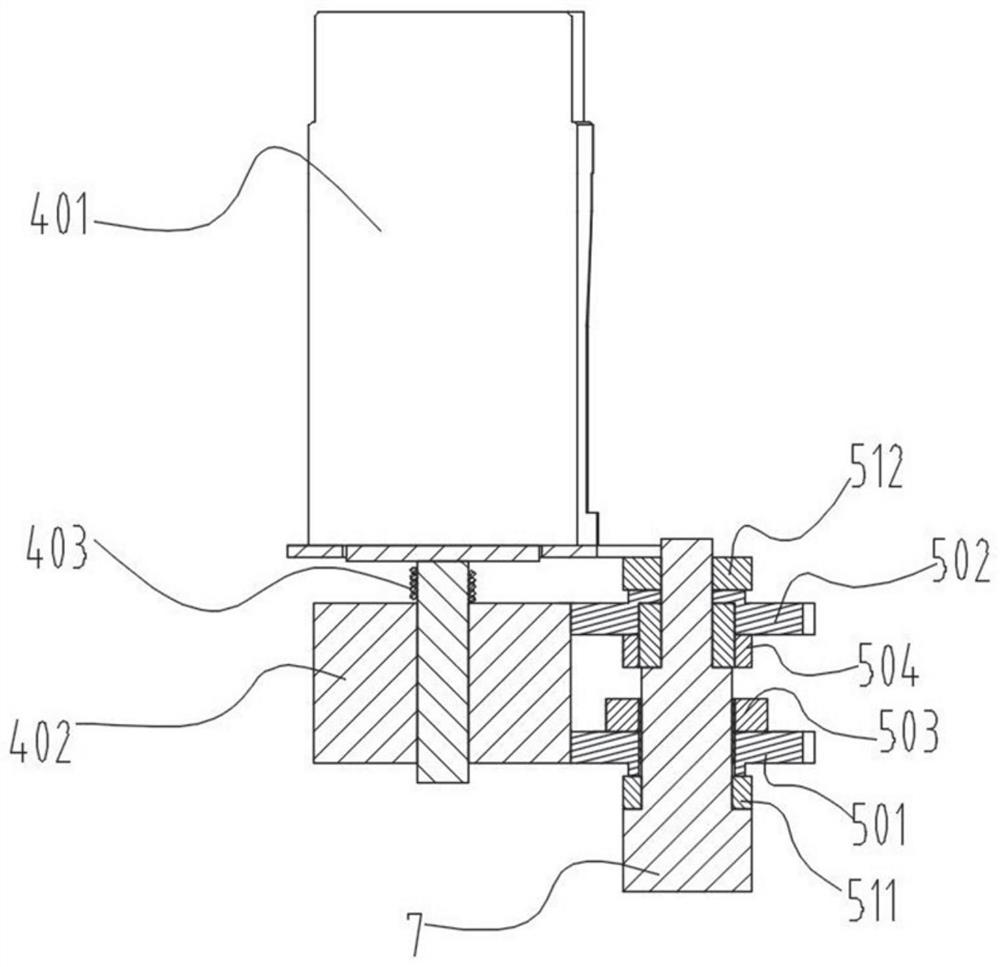

[0035] Such as Figure 1-4As shown, the present embodiment provides a kind of SCARA robot, and this robot is a kind of lightweight SCARA robot, and it comprises base 1, first mechanical arm 2 and second mechanical arm 3, and first mechanical arm 2 is rotatably arranged Above the machine base 1, the other end is rotatably set together with the second mechanical arm 3; that is, the first mechanical arm 2 is arranged at the end of the machine base 1, and the end of the machine base 1 is provided with a motor that can drive the first mechanical arm 2 to move. The second drive motor (i.e. the first joint motor) makes the first mechanical arm 2 and the mechanism connected with it rotatable around the base; the second mechanical arm 3 is located at the end of the first mechanical arm 2, and is The joint of arm 2 is provided with the 3rd driving motor 8 (being the second joint motor), can drive the second mechanical arm 3 and the mechanism connected with it can rotate around the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com