Embossing device for polyvinyl chloride (PVC) tablecloth processing

A technology for embossing and tablecloth, which is applied in the field of embossing devices for PVC tablecloth processing, and can solve the problems of poor embossing effect of PVC base

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

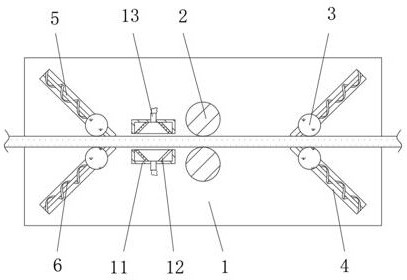

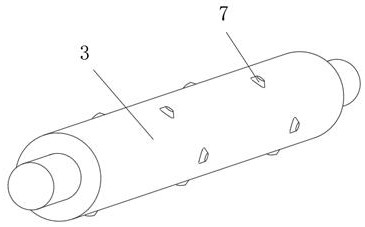

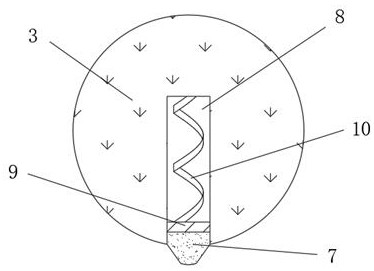

[0029] refer to Figure 1-4 , an embossing device for PVC tablecloth processing, comprising a fixed frame 1, two embossing rollers 2 are rotatably connected to the middle position between the inner walls at both ends of the fixed frame 1, and the embossing rollers 2 are located between the inner walls at both ends of the fixed frame 1 Two limit rollers 3 are rotatably connected on both sides of the fixed frame 1, and the position corresponding to the limit roller 3 on the inner wall of the two ends of the fixed frame 1 is provided with a limit groove 4 arranged obliquely, and the top of the limit groove 4 is far away from the embossing roller. One side of 2 is inclined, the inner wall of the limiting groove 4 is slidingly connected to the limiting block, and the end of the limiting roller 3 is connected to the limiting block in rotation, and a limiting rod is fixed between the top and bottom inner walls of the limiting groove 4 5, and the middle position of the top of the limi...

Embodiment 2

[0035] refer to Figure 5-6 , an embossing device for PVC tablecloth processing, two airflow parts 15 are fixed on the side of the embossing roller 2 away from the auxiliary box 11 between the inner walls of the two ends of the fixed frame 1, and the inside of the airflow part 15 is hollow. The opposite outer walls of the air flow parts 15 are fixed with a plurality of ventilation pipes 16, and the opposite outer walls of the two air flow parts 15 are provided with a plurality of ventilation holes 17, and the opposite outer walls of the two air flow parts 15 are all arranged as an outwardly arched arc surface structure.

[0036] When in use, use the ventilation pipe 16 on the top of the airflow part 15 and the ventilation hole 17 at the bottom to carry out the blowing operation on the surface of the PVC base layer, and use the arc surface at the bottom of the airflow part 15 to ensure the effect of uniform heat dissipation on the surface of the PVC base layer, and through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com