A kind of cracking method of solid hazardous waste

A hazardous waste and solid technology, applied in the field of pyrolysis, can solve the problems of material residue easily remaining inside the cylinder, material heating is not uniform enough, filter blockage, etc., to achieve the effect of avoiding residue, reducing residue, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] as attached figure 1 To attach Figure 8 Shown:

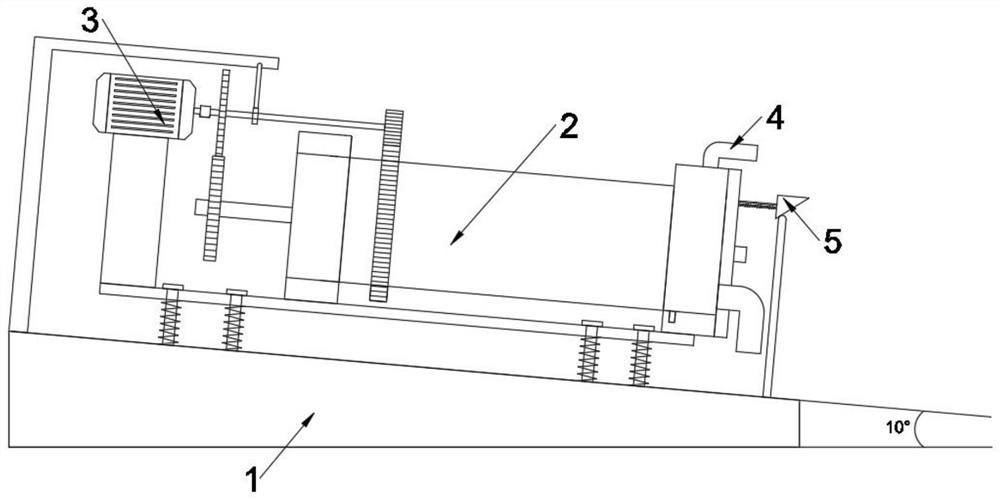

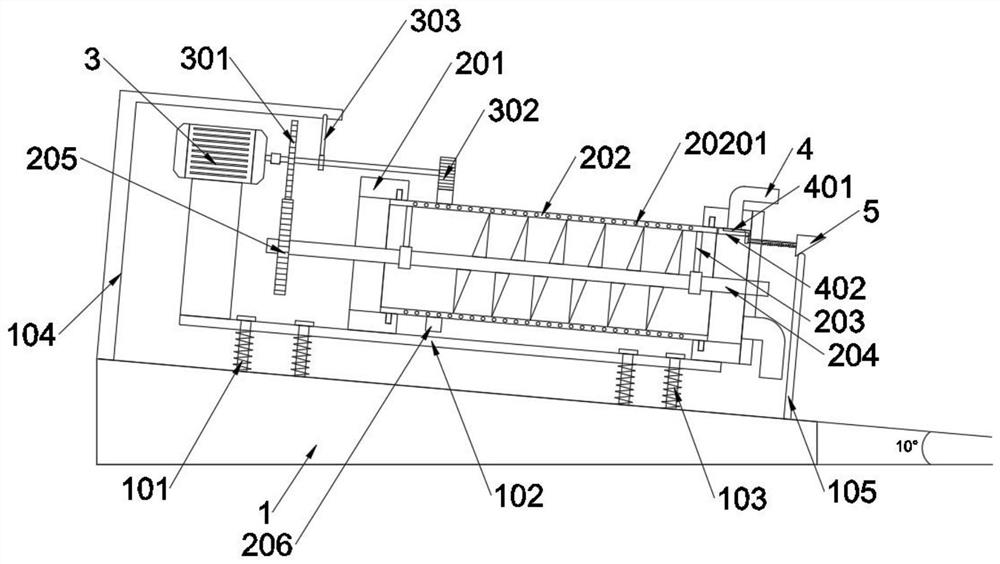

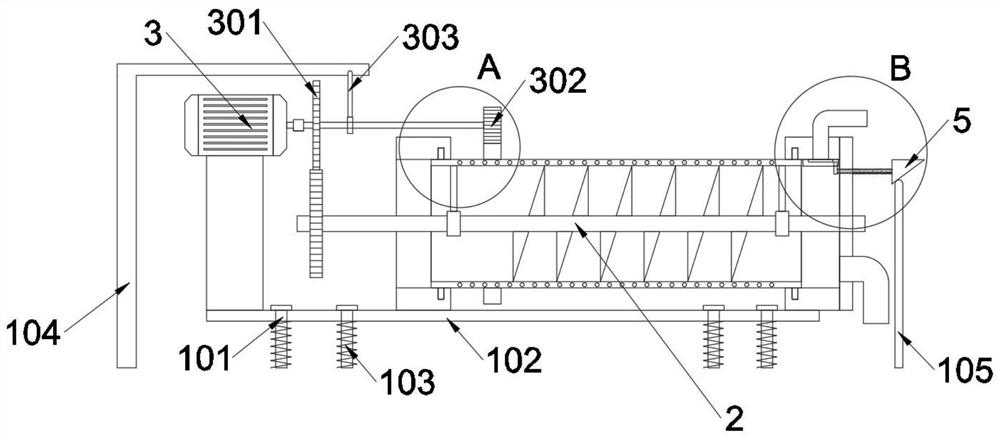

[0035] The invention provides a method for pyrolysis of hazardous solid waste. The method realizes the pyrolysis of hazardous solid waste through a solid hazardous waste pyrolysis equipment equipped with a base 1, a drive structure 2, a drive motor 3, a smoke exhaust pipe 4, and a cleaning structure 5;

[0036] The solid hazardous waste pyrolysis equipment includes a base 1 and a force block 504; a drive structure 2 is installed on the base 1, and a drive motor 3 is also installed on the base 1; a smoke exhaust pipe 4 is installed on the drive structure 2, and the drive A cleaning structure 5 is also installed on the structure 2; refer to as image 3 and Image 6, the base 1 also includes a force seat 104, the force seat 104 is welded on the base 1, and the force seat 104 is an L-shaped structure; the drive motor 3 also includes a toggle lever B303, and the toggle lever B303 is installed on the drive motor 3 On the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com