Cloth airing frame and method for lower cloth to dry faster

A cloth, slow technology, used in the field of drying racks, can solve the problem of uneven color of the cloth, and reduce the possibility of damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

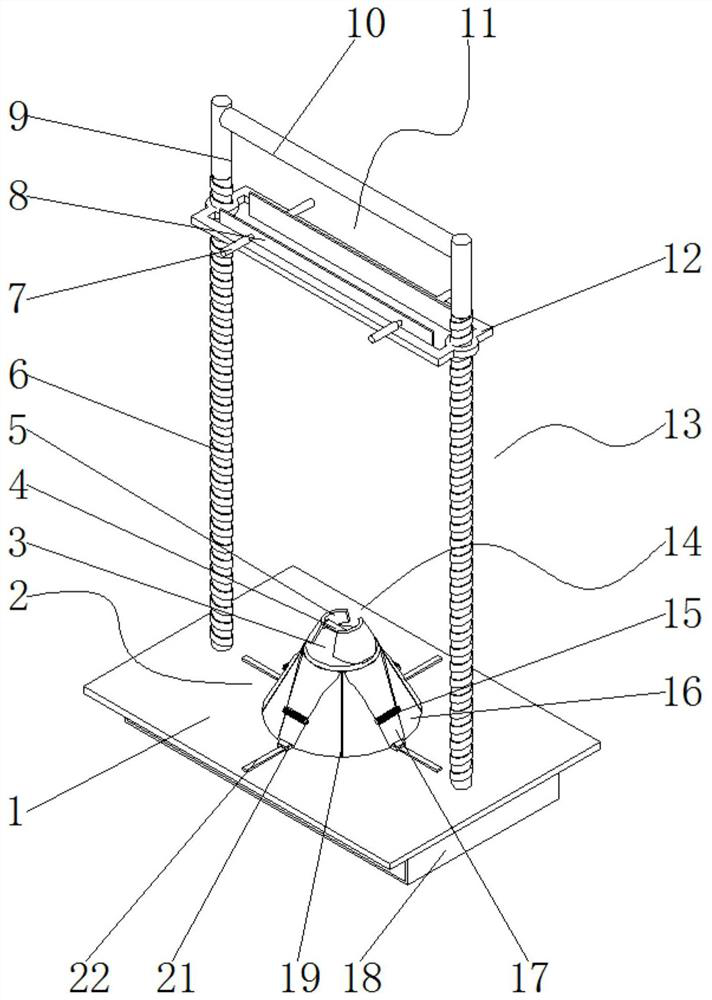

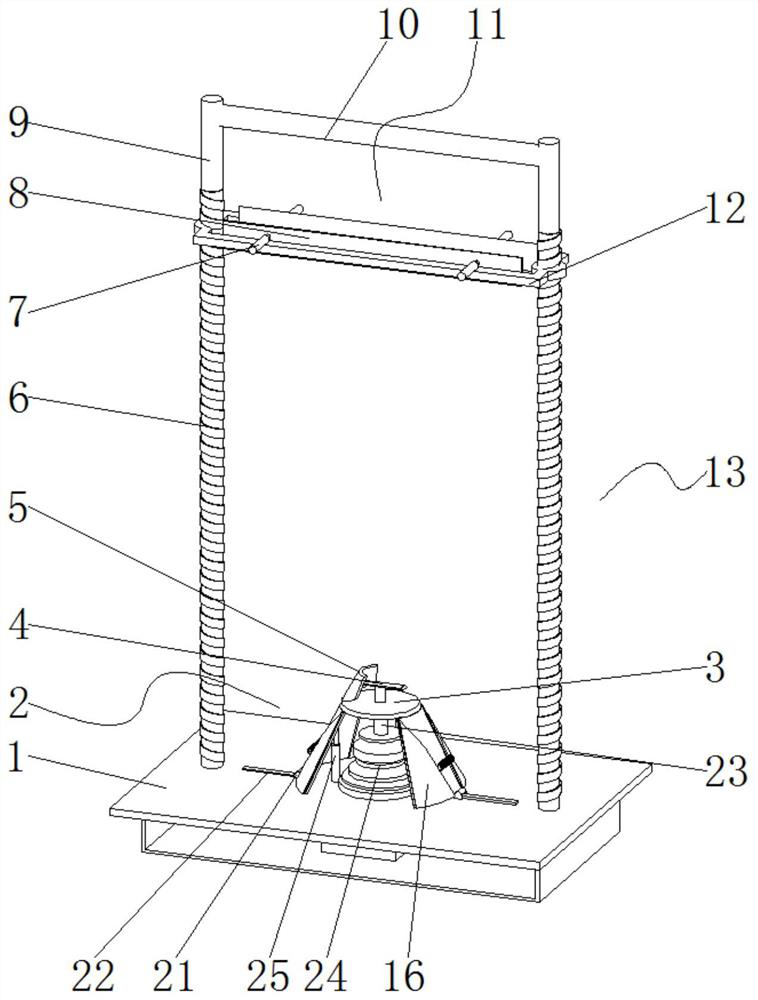

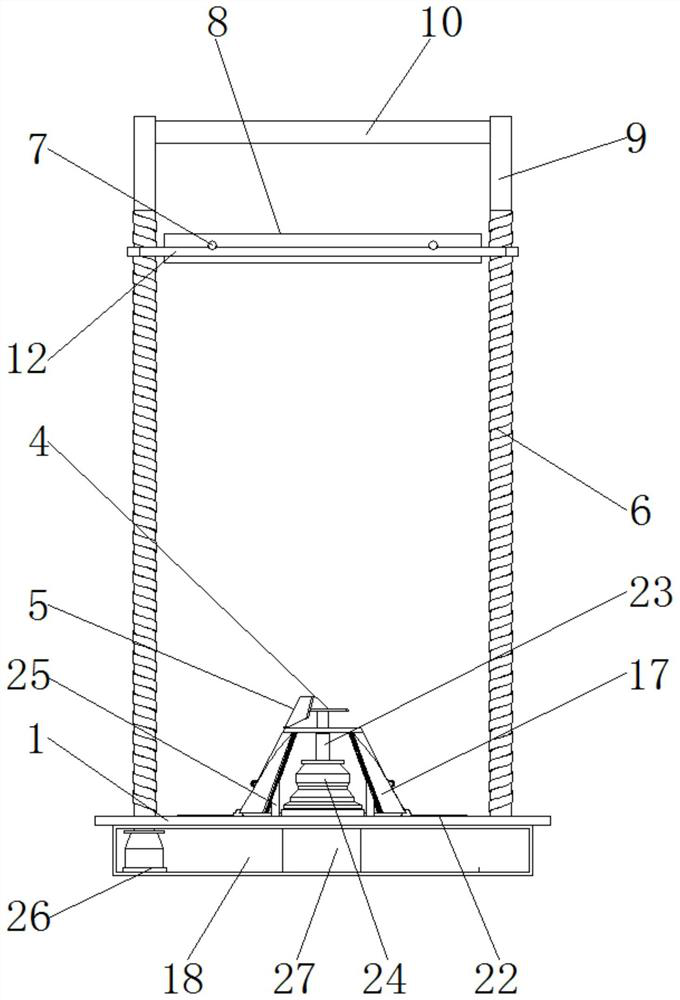

[0032] Embodiments of the present invention provide a cloth drying rack and method that can solve the problem of drying cloth at low places, such as Figure 1-5 As shown, it includes a bottom plate 1 , a lifting mechanism 13 , a crossbeam 10 , a fixing assembly 14 and four guide mechanisms 2 . Both the fixing assembly 14 and the lifting mechanism 13 are arranged on the bottom plate 1 . The lifting mechanism 13 is provided with cloth, and the four guide mechanisms 2 are equiangularly distributed around the fixed component 14 with the fixed component 14 as the center. The flow guide mechanism 2 includes a slideway 22 , a slider 21 , a water wheel 15 , a sensor 20 for testing the rotating speed of the water wheel 15 , an electric telescopic rod 25 , and a deflector 16 . The slideway 22 is arranged radially around the fixing component 14 with the fixing component 14 as the center. The slider 21 is slidingly fitted on the slideway 22 . The bottom end of the deflector 16 is hinge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com