Condensed water controlling method of clothing treatment equipment and clothing treatment equipment

A technology for clothes treatment equipment and control methods, which is applied to household clothes dryers, textiles, papermaking, washing devices, etc., and can solve problems such as blockage of water vapor circulation, aggravated accumulation of condensed water, and failure to achieve sealing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

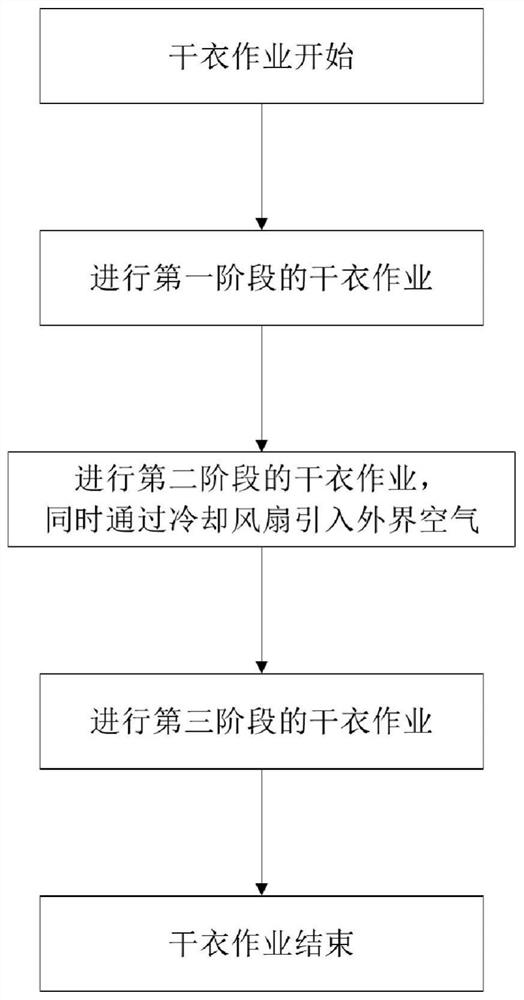

[0038] Such as figure 1 As shown, the present embodiment provides a method for controlling condensed water of clothes processing equipment. In this method, the process of drying clothes includes an initial stage, an intermediate stage, and an end stage in sequence. The outside air is introduced into the equipment to accelerate the circulation of the internal air to suppress the generation of condensed water.

[0039] In the drying process of the present invention, since the wet load (clothes to be dried) has no heat accumulation in the initial stage, water vapor will not be formed, so that condensed water will not be formed, and the load will be close to drying in the final stage. The moisture content in the air is very little, neither water vapor nor condensed water will be formed. Using the cooling fan in the existing equipment does not increase the cost of the hardware. The introduction of external air in the middle stage is more targeted and avoids energy In the drying st...

Embodiment 2

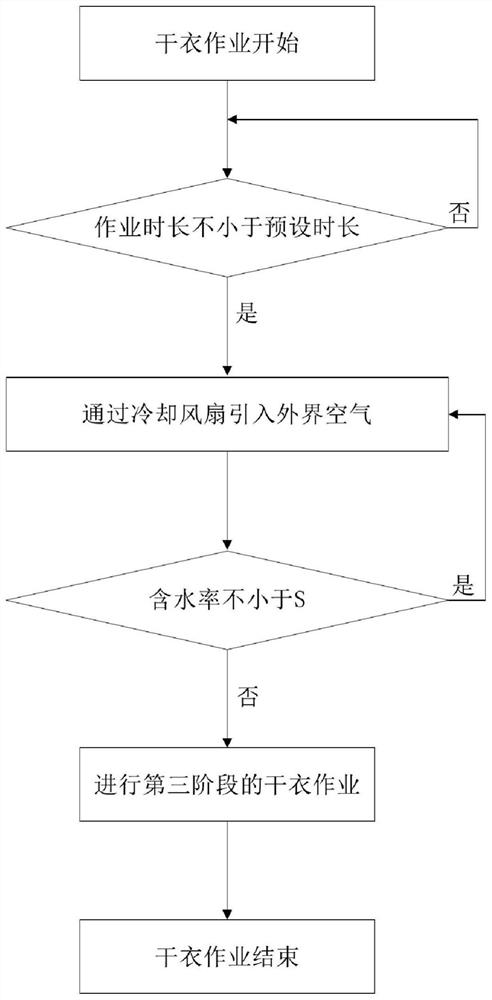

[0046] Such as figure 2 As shown, this embodiment provides a condensed water control method for laundry treatment equipment. On the basis of Embodiment 1, the specific control method of the nodes between the middle stage and the initial stage and the end stage is further optimized: dry After the laundry operation starts, it enters the initial stage, and the drying operation is carried out. When the operation time is not less than the preset time length, the drying operation enters the intermediate stage. When the drying operation enters the intermediate stage, the moisture content of the processed clothes is judged; If the moisture content of the laundry is less than the preset value S, the drying operation enters the end stage.

[0047] The preset value S of moisture content can be 5-20% according to specific conditions such as the type of clothes, and in this embodiment, it is preferably 10%.

[0048]In the method of this embodiment, after the preset duration of the drying...

Embodiment 3

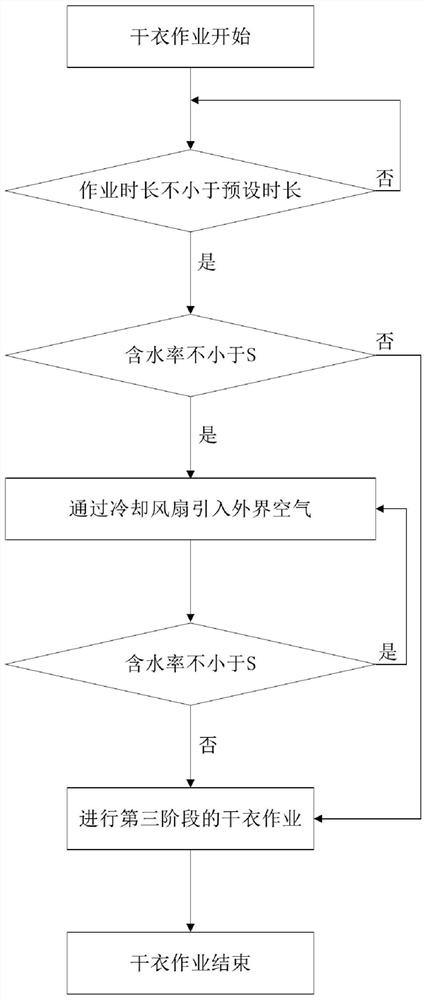

[0050] Such as image 3 As shown, this embodiment provides a condensed water control method for laundry treatment equipment, which is different from Embodiment 2 in that the specific control method of nodes between the initial stage and the intermediate stage: in addition to the operation time, it also increases Moisture standard.

[0051] Specifically, after the drying operation starts, it enters the initial stage, and the drying operation is carried out. When the operation time is not less than the preset time length, it is judged whether the moisture content of the clothes is not less than the preset value S, and if it is not less than the preset value S, then Enter the middle stage.

[0052] In this embodiment, the moisture content preset value S may be 5-20% according to specific conditions such as the type of clothes, and in this embodiment, it is preferably 10%.

[0053] In the method of this embodiment, the node between the initial stage and the intermediate stage is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com