Cast-in-place box girder construction method

A box girder construction and cast-in-situ technology, applied in bridges, bridge materials, bridge construction, etc., can solve problems such as poor safety and difficult construction of cast-in-place box girder, improve bearing performance, and reduce the difficulty of lashing and hoisting construction. , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

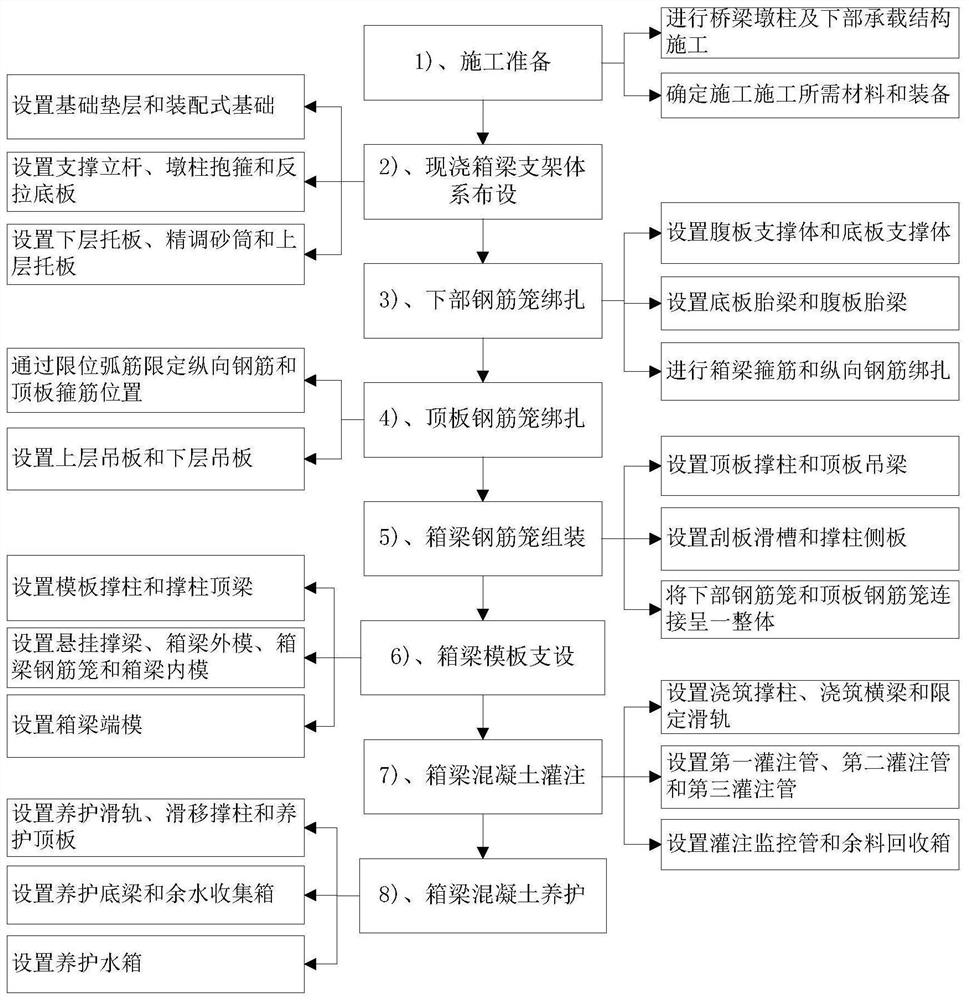

[0053] like Figure 1-Figure 13 As shown, the cast-in-place box girder construction method is characterized in that: comprising the following steps:

[0054] 1. Construction preparation:

[0055] Carry out the construction of the bridge pier column 1 and its lower bearing structure, determine the concrete mix ratio, and prepare the devices required for the construction;

[0056] 2. Layout of cast-in-place box girder support system:

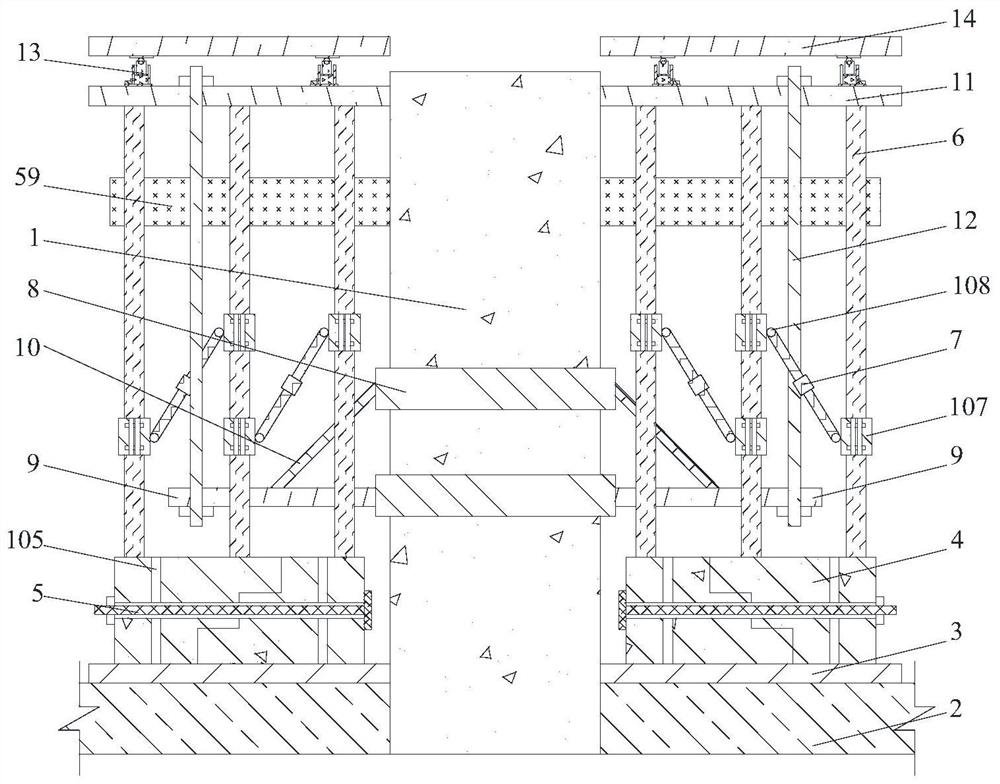

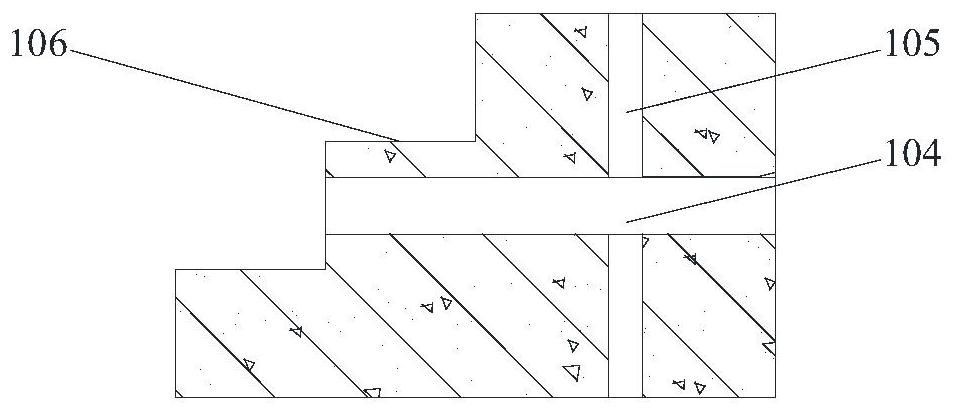

[0057] On the foundation soil 2 on both sides of the bridge pier column 1, a foundation cushion 3 and a prefabricated foundation 4 are arranged in sequence from bottom to top, wherein each prefabricated foundation 4 is composed of two parts that are superimposed and connected by step slopes, and The two parts of the prefabricated foundations 4 that are superimposed and connected are firmly connected by the foundation fas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com