Bamboo winding composite pipe gallery with high fire endurance and preparation method thereof

A technology of fire-resistant limit and composite pipes, which is applied in fire protection, electric fire alarms, water conservancy projects, etc., can solve the problem of the inability to give full play to the application potential of bamboo winding composite pipe galleries, the poor fire resistance of bamboo winding composite pipe galleries, and the impact on The service life of the pipe gallery and other issues can be avoided to avoid the risk of fire penetration, reduce the application cost and increase the self-weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

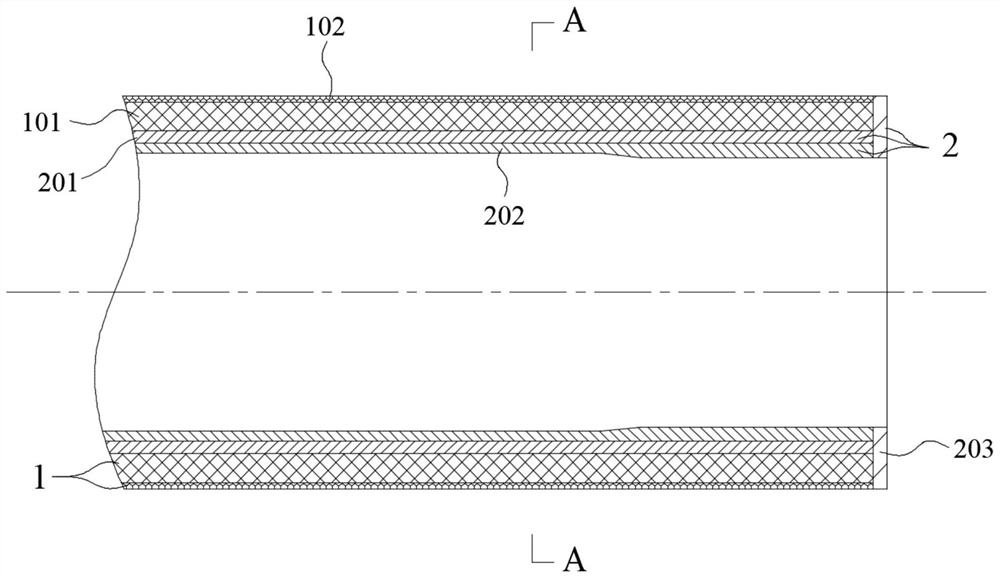

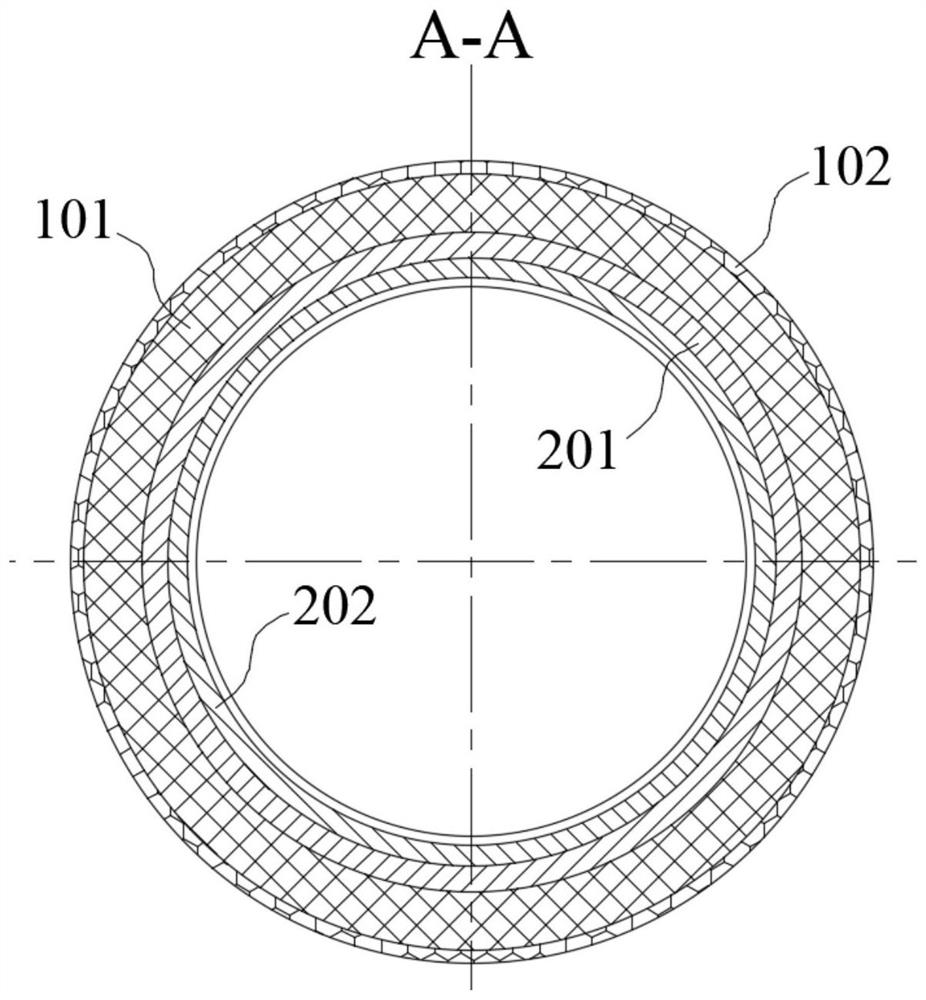

[0048] see figure 1 , 2 The bamboo winding composite pipe gallery with high fire resistance in the preferred embodiment of the present invention includes a pipe gallery main body 1 and a fireproof layer 2 arranged on the inner circumference and end of the pipe gallery main body 1 .

[0049] Specifically, the main body 1 of the pipe gallery in the preferred embodiment preferably includes a structural layer 101 and an outer protective layer 102 arranged in sequence from the inside to the outside in the radial direction. Wherein, the structural layer 101 is formed by bonding and curing bamboo strip materials with resin. Specifically, the bamboo strip material in the preferred embodiment includes axial bamboo strip curtains and circumferential bamboo strip curtains, and the axial bamboo strip curtains and the circumferential bamboo strip curtains are arranged alternately in the radial direction until solidified to form a structure with good integrity Layer 101. Further, after t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com