Fabricated concrete frame beam and column dry type connection joint

A technology for connecting joints and concrete, which is applied in the direction of construction and building construction, can solve the problems of insufficient shear force, insufficient seismic performance, and inconvenient construction of the beam-column joint surface, so as to improve the anti-seismic ability, reliable anchorage measures, The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

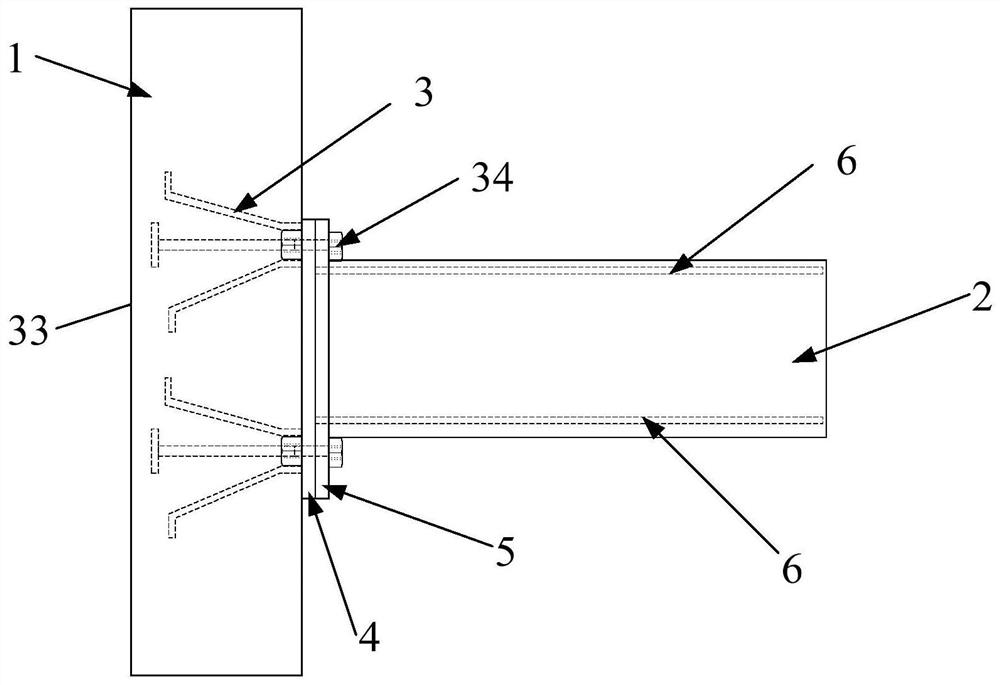

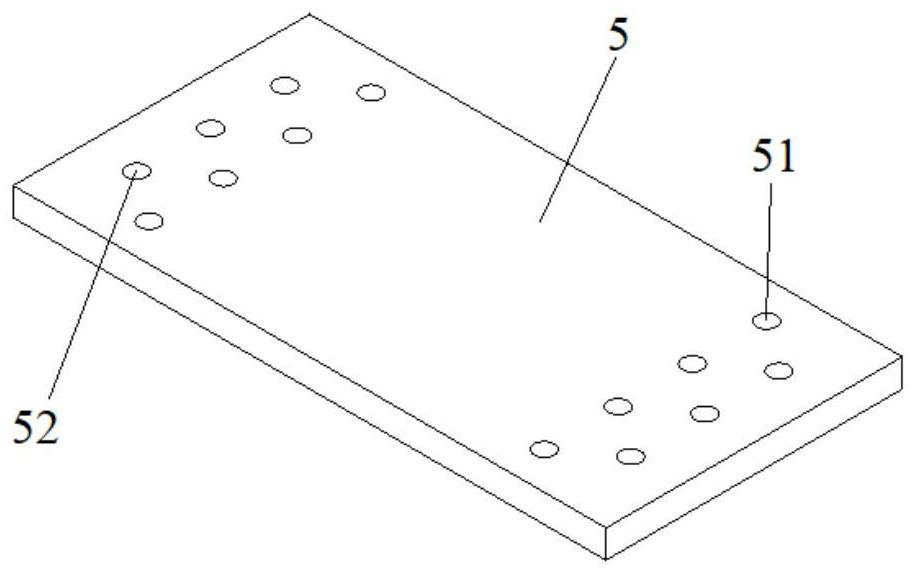

[0025] Such as figure 1 As shown, a prefabricated concrete frame beam-column dry connection node of the present invention includes a precast concrete column 1 and a precast concrete beam 2, and also includes a column side steel plate 4 fixedly connected to the connection side of the precast concrete column 1 on the back and a steel plate 4 on the back and The beam ends of the precast concrete beams 2 are fixedly connected to the steel plates 5;

[0026] The connecting steel plate 4 at the column side is opposite to the connecting steel plate 5 at the beam end, and is detachably fixedly connected.

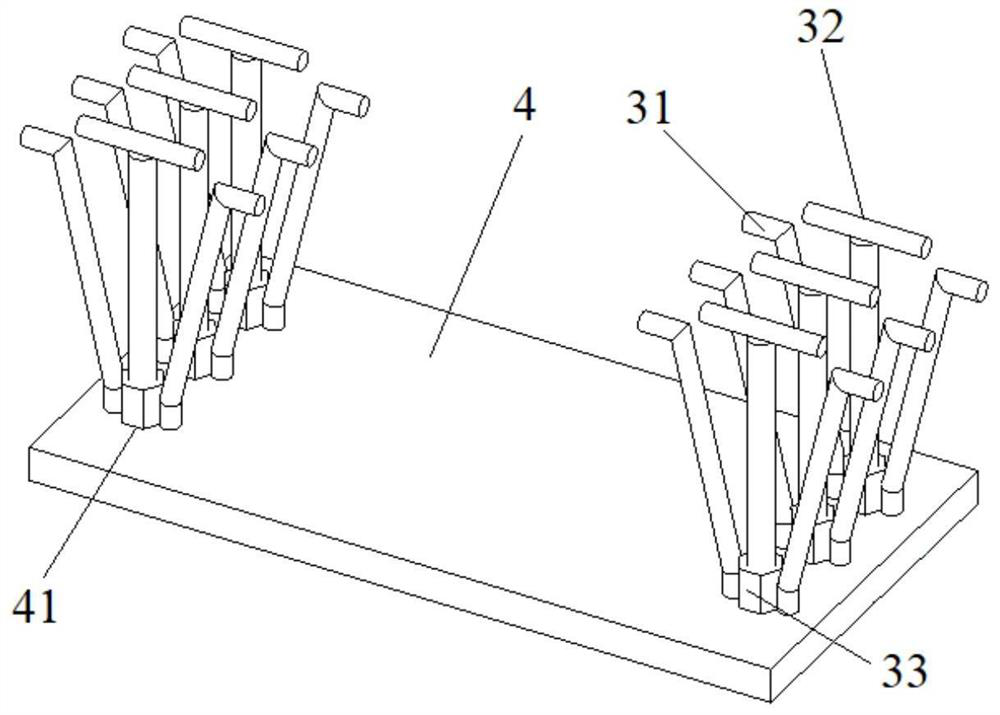

[0027] Preferably, the back of the column side steel plate 4 is provided with an anchor bar 3 , one end of the anchor bar 3 is fixedly connected to the back of the column side steel plate 4 , and the rest is pre-embedded in the precast concrete column 1 .

[0028] Such as figure 2 As shown, the anchor bar 3 includes a T-shaped steel bar 31, at least two L-shaped steel bars 32 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com