Disk spring assembly, motorized spindle, machining equipment

A technology of electric spindle and disc spring, which is applied in the direction of metal processing equipment, mechanical equipment, metal processing machinery parts, etc., can solve the problems of cumbersome installation process, affecting the performance of the disc spring body, difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The first embodiment of disc spring assembly and electric spindle

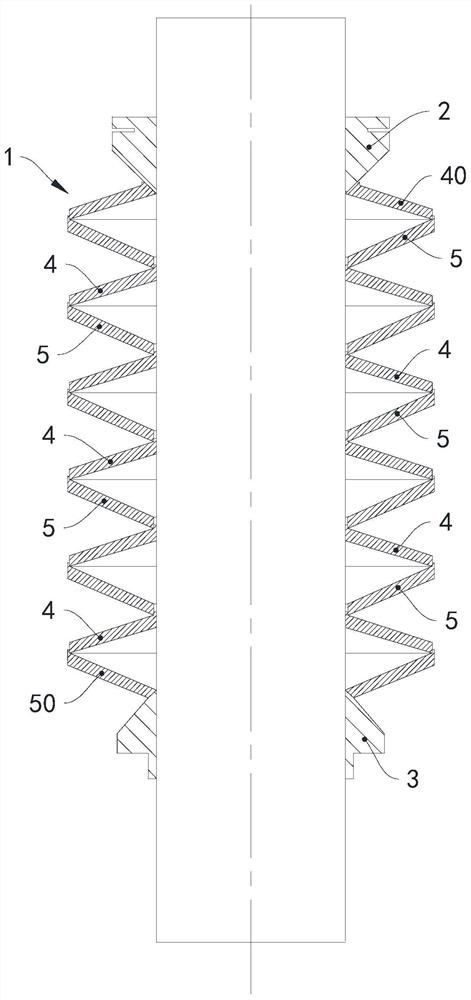

[0044] see figure 1 , The electric spindle includes a disc spring assembly 1 , a first work piece 2 , a second work piece 3 and a pull rod 3 .

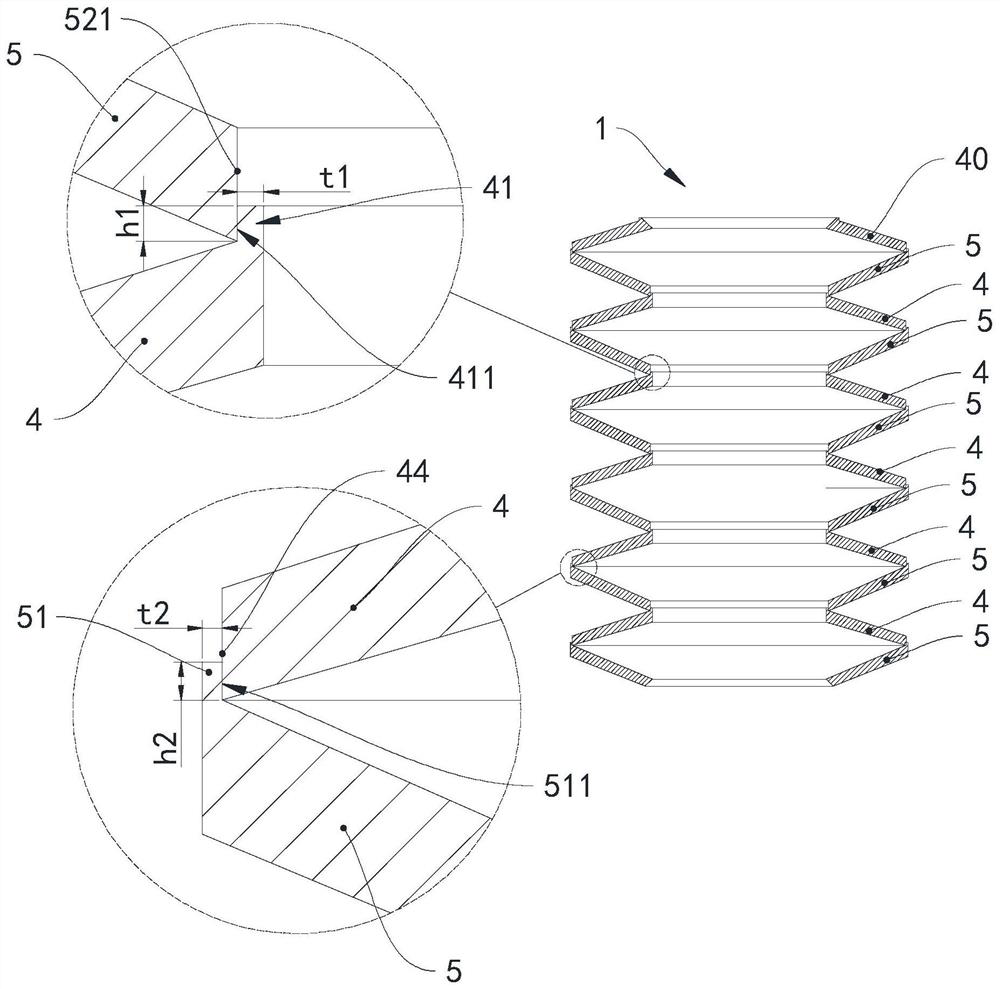

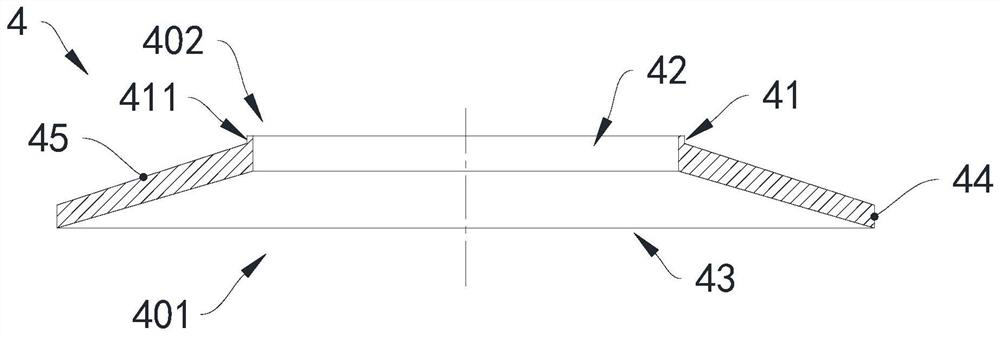

[0045] Disc spring assembly 1 includes six first disc spring bodies and six second disc spring bodies coaxially arranged, and the first disc spring bodies and the second disc spring bodies are arranged alternately along the axis, because the first disc spring body and the second disc spring body are arranged alternately along the axis, because the first disc spring body located at the end The structures of the remaining five first disc spring bodies outside a disc spring body are identical, and the structures of the remaining five second disc spring bodies except the second disc spring body at the end are identical. For ease of description, they are arranged at the end The first disc spring body is the first disc spring body 40, the remaining five first disc s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com