High-precision lens anti-blue-ray detector

An anti-blue light, high-precision technology, applied in the direction of testing optical performance, etc., can solve the problems that affect the use of the detection device, the cumbersome process of disassembly and detection, and the inability to detect the position display, etc., to achieve accurate accuracy, reduce the difficulty of repair, and facilitate observation and inspection. The effect of repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

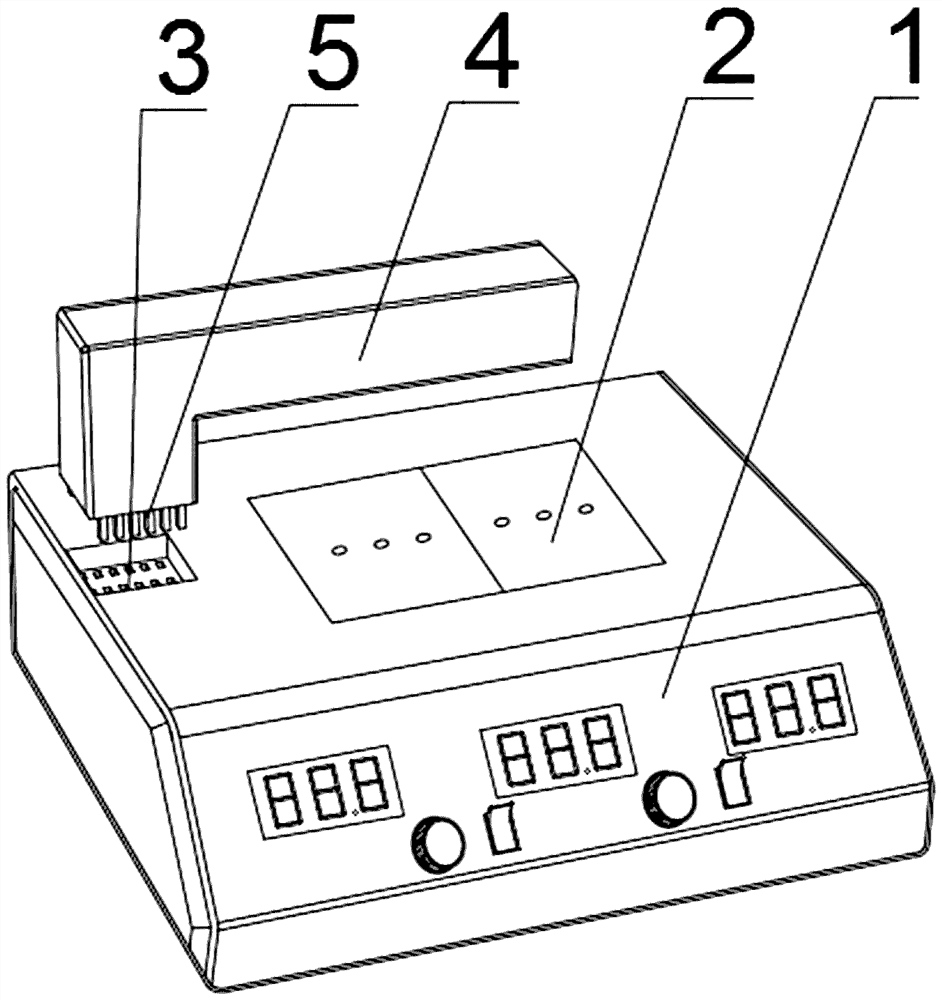

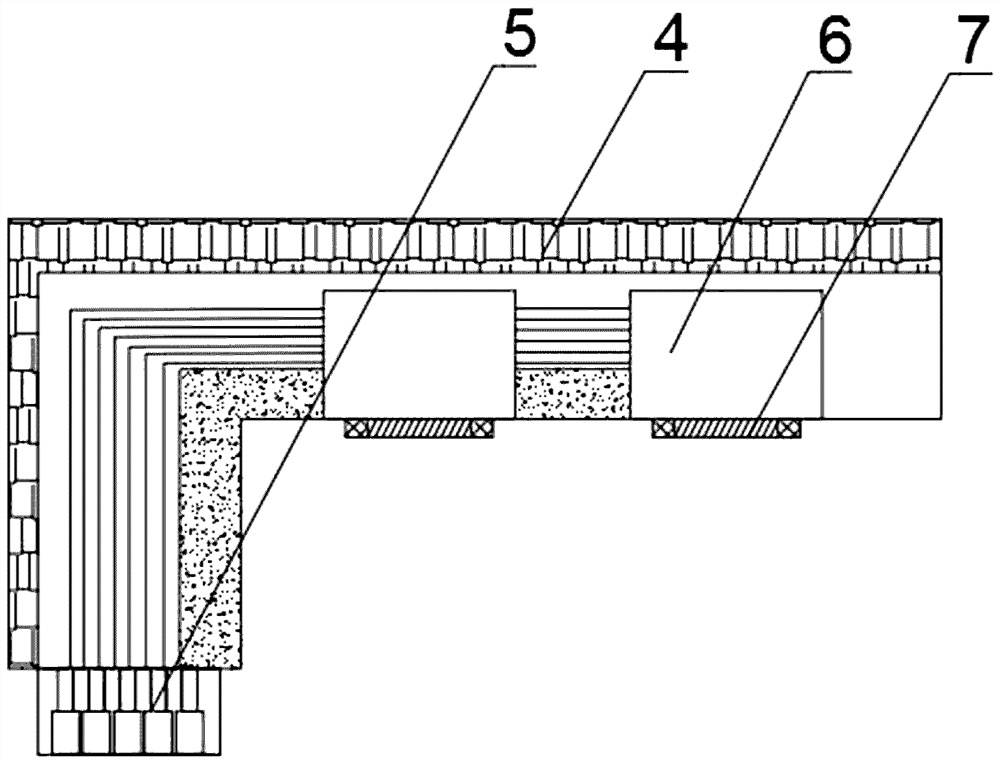

[0027] like Figure 1-5 As shown, the present invention provides a high-precision lens anti-blue light detector, including a protective housing 1, a receiving plate 2 is fixedly installed at the center of the top outer surface of the protective housing 1, and a plurality of through-holes are provided on the top outer surface of the receiving plate 2. hole, the top outer surface of the protective shell 1 is provided with a docking groove 3 near one side, and the inner surface of the docking groove 3 is movably installed with a detection frame 4, and the side of the detection frame 4 near the docking groove 3 is welded with a docking pin. A plurality of copper pins 5 are welded on the outer surface of the bottom end of the test frame 4, and a transmitter 6 is fixed and installed by bolts at a position close to the receiving plate 2 inside the detection frame 4.

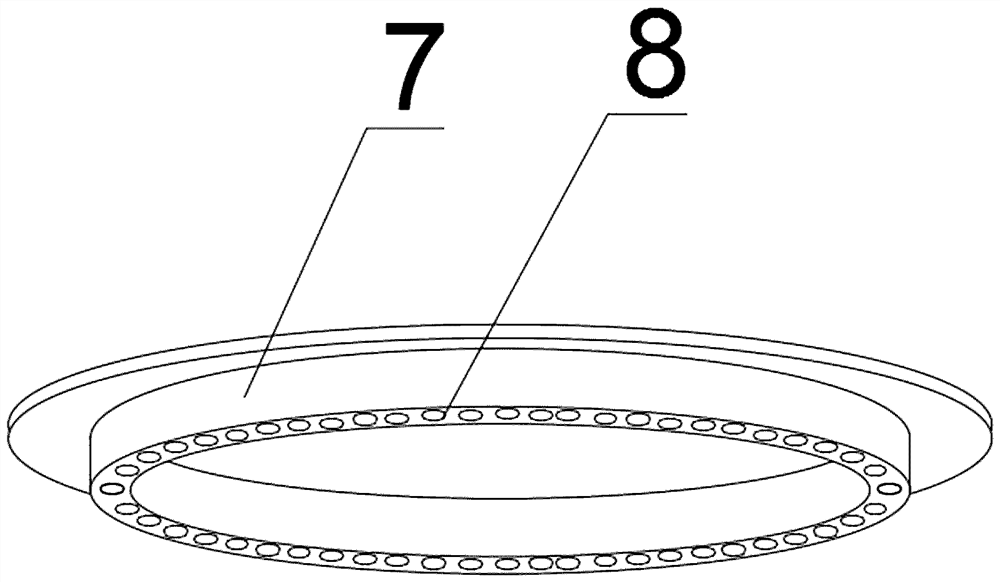

[0028] refer to image 3 As shown, a detection ring 7 is fixedly installed on the outer surface of the bottom end of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap