Light machine module and projector

一种光机模块、投影机的技术,应用在光学、光学元件、仪器等方向,能够解决光阀使用寿命降低、温差大内应力、多噪音等问题,达到提高散热效果、佳投影品质的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of a preferred embodiment with reference to the accompanying drawings. The directional terms mentioned in the following embodiments, such as: up, down, left, right, front or back, etc., are only referring to the directions of the drawings. Accordingly, the directional terms are used to illustrate and not to limit the invention.

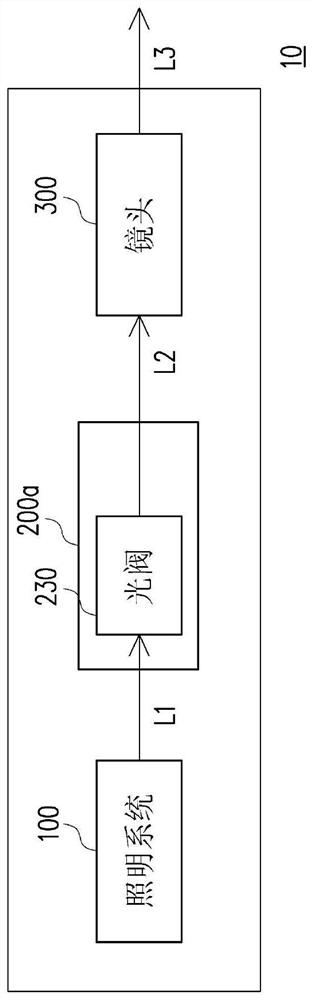

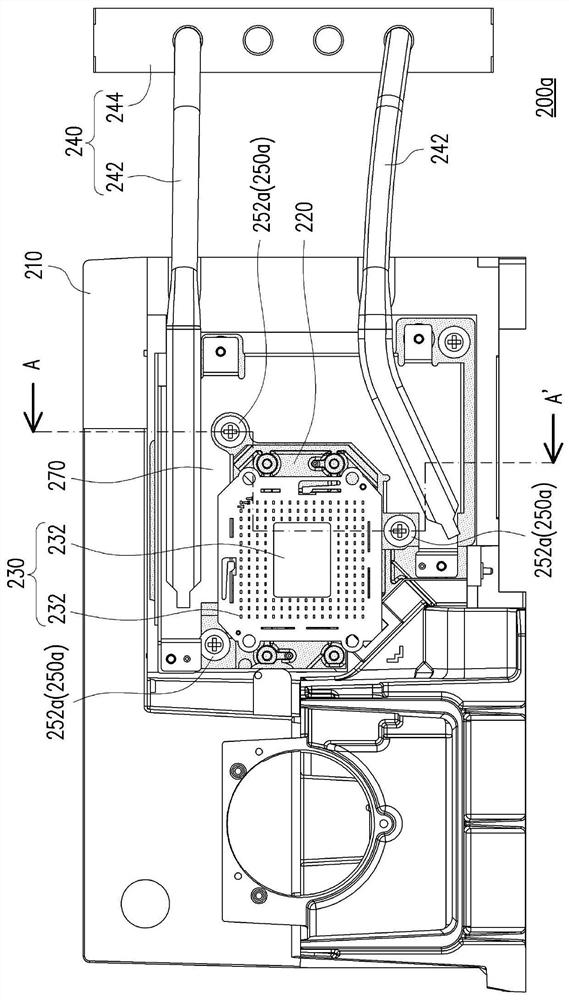

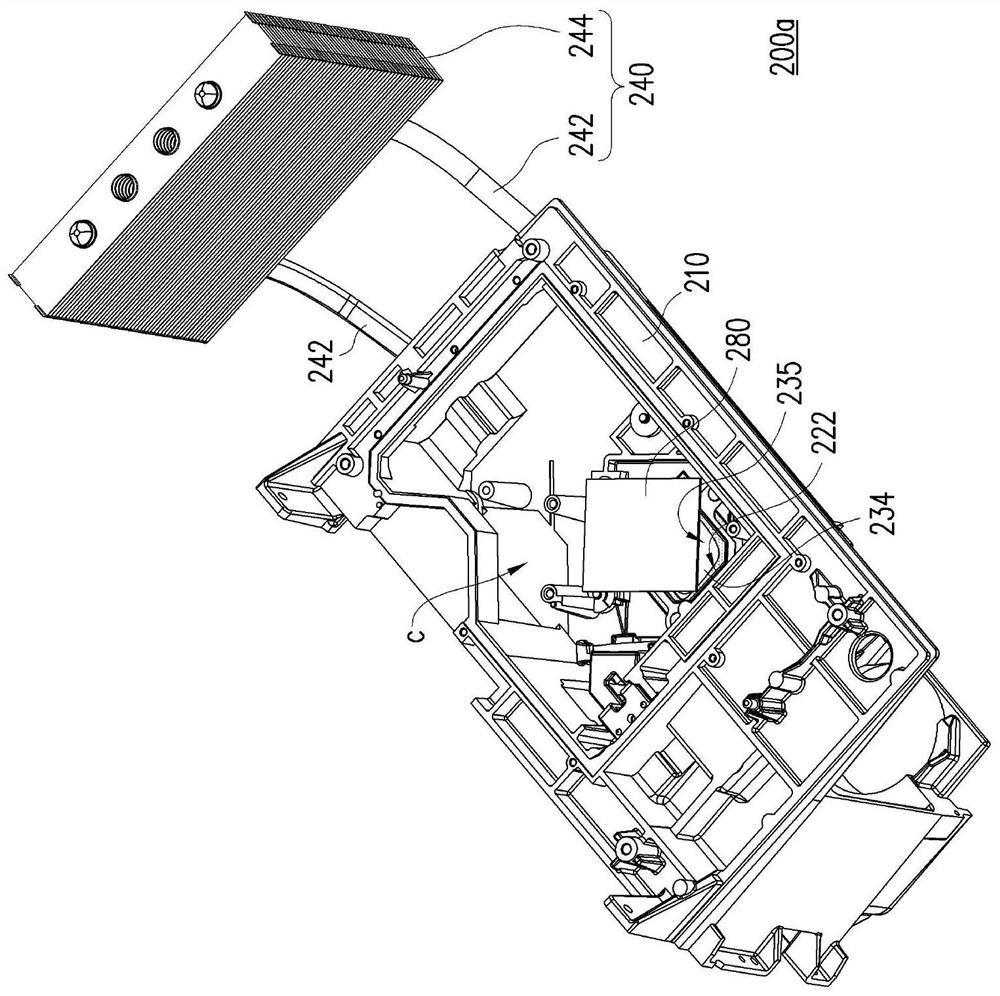

[0062] figure 1 It is a schematic diagram of a projector according to an embodiment of the present invention. Please refer to figure 1 , the projector 10 of this embodiment includes an illumination system 100 , an optical-mechanical module 200 a and a lens 300 . The illumination system 100 is used for providing an illumination beam L1. The light valve 230 of the optical-mechanical module 200a is located on the transmission path of the illumination beam L1 for modulating the illuminati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com