A High Reliability and Long Life Limit Interrupter

An arc extinguishing chamber and long-life technology, which is applied in the direction of electrical components, electric switches, circuits, etc., can solve the problems of reducing product life, reducing the contact area of dynamic and static contacts, and increasing structural complexity, so as to achieve long life and ensure effective The effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

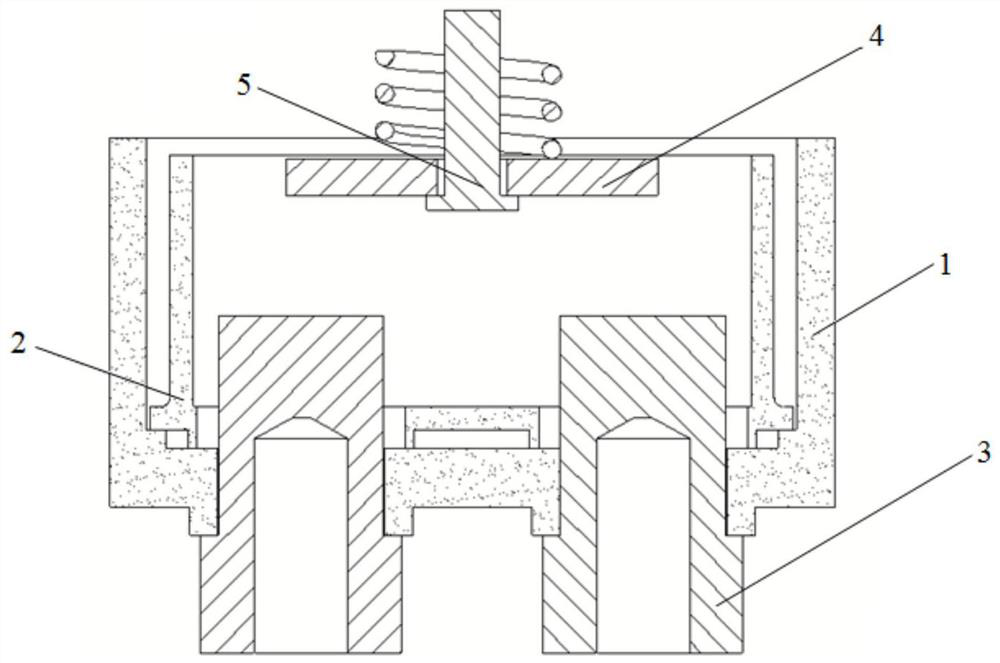

[0050] like figure 1 , In this embodiment, the high reliability and long life limit arc extinguishing chamber includes: an outer arc extinguishing chamber 1 , an inner arc extinguishing chamber 2 , two static contacts 3 and a moving contact 4 . Among them, the outer arc extinguishing chamber 1 and the inner arc extinguishing chamber 2 are nested and installed into one body, which are assembled and fixed by brazing; the movable contact 4 is arranged on the top of the outer arc extinguishing chamber 1; the two static contacts 3 are arranged at the bottom of the outer arc extinguishing chamber 1 , fixed by brazing assembly.

[0051] Preferably, the high-reliability and long-life limit arc-extinguishing chamber may further include: a driving rod 5 . The movable contact 4 is assembled and fixed with the drive system through the drive rod 5, so as to realize the switching function.

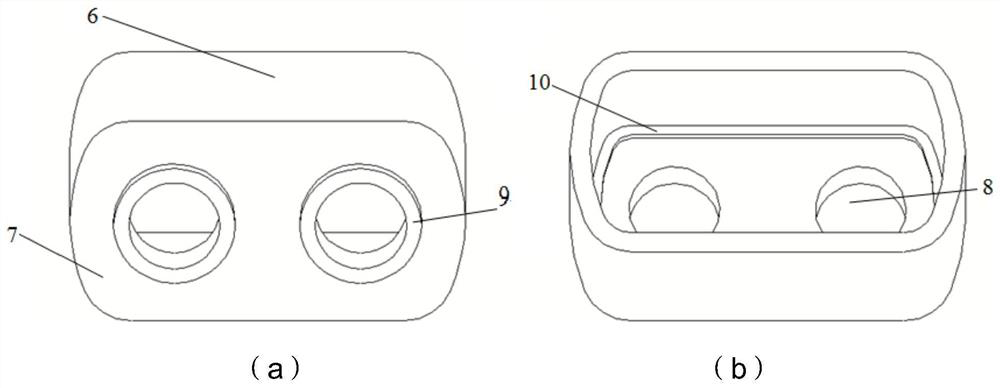

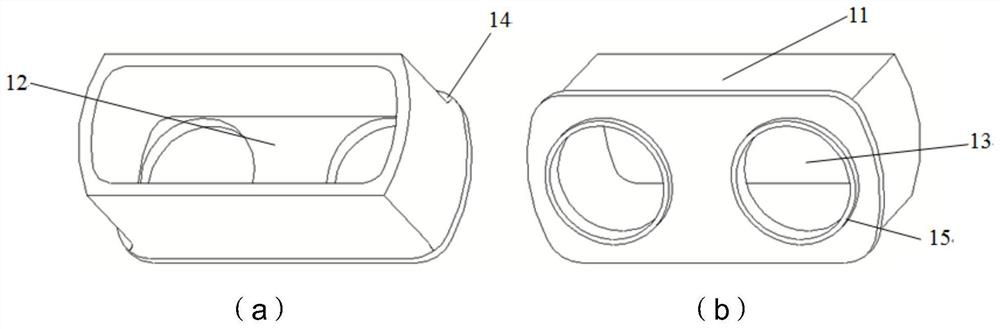

[0052] In a preferred embodiment of the present invention, as figure 2 , the outer arc-extinguis...

Embodiment 2

[0062] On the basis of the above-mentioned embodiment, the working process of the high-reliability and long-life limit arc extinguishing chamber is briefly described below: the driving system drives the moving contact 4 to go down and contacts with the two static contacts 3, so as to connect the moving contact The head 4 and the static contact 3 are connected in series in a loop to achieve closure; the driving system drives the moving contact 4 to go up and separate from the two static contacts 3 to achieve shutdown.

[0063] like Figure 8 As shown, when the moving contact 4 and the static contact 3 are disconnected, an arc is generated between the contacts, and the contacts are ablated to produce splashes; the internal contacts 16 of the static contact 3 and the moving contact 4 are always in the inner arc extinguishing chamber 2 intracavity. After the arc is broken, most of the splashes are attached to the cavity of the inner arc extinguishing chamber 2; since the inner ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com