Sealant material composition and pneumatic tire

A material composition and pneumatic tire technology, applied in the field of pneumatic tires and sealant material compositions, can solve problems such as reduced sealing performance, adverse effects on handling stability and other driving performance, and achieve suppressed sealing performance, good processability, and improved The effect of processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

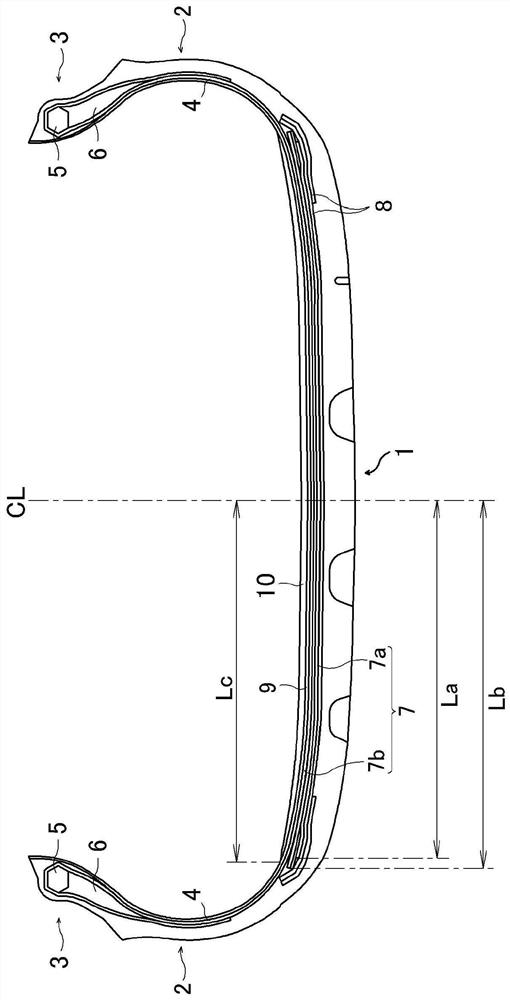

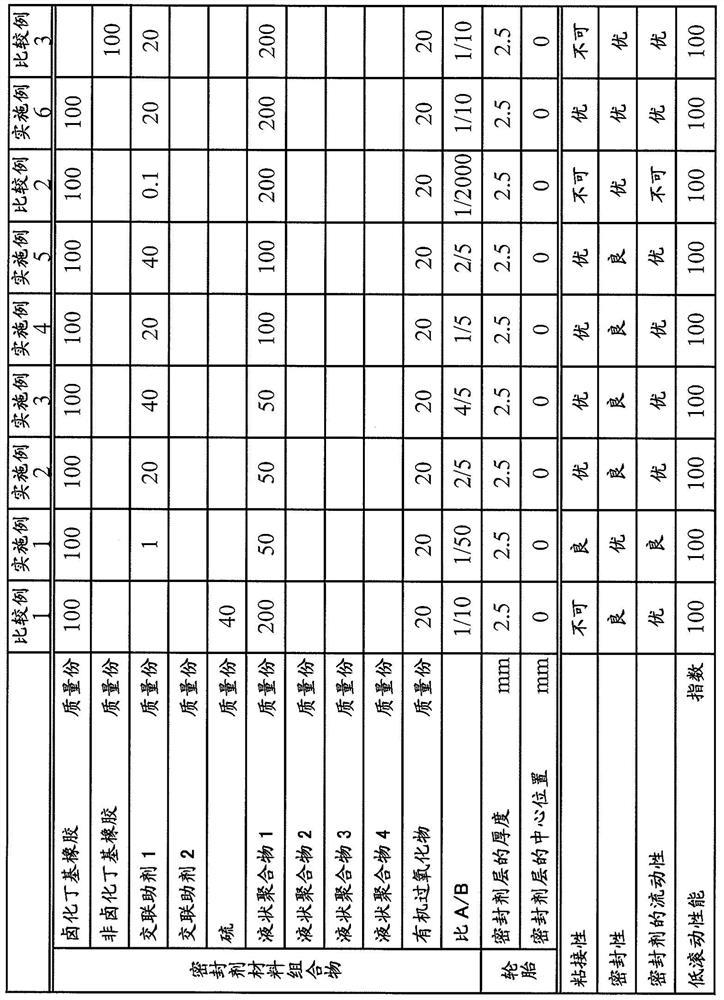

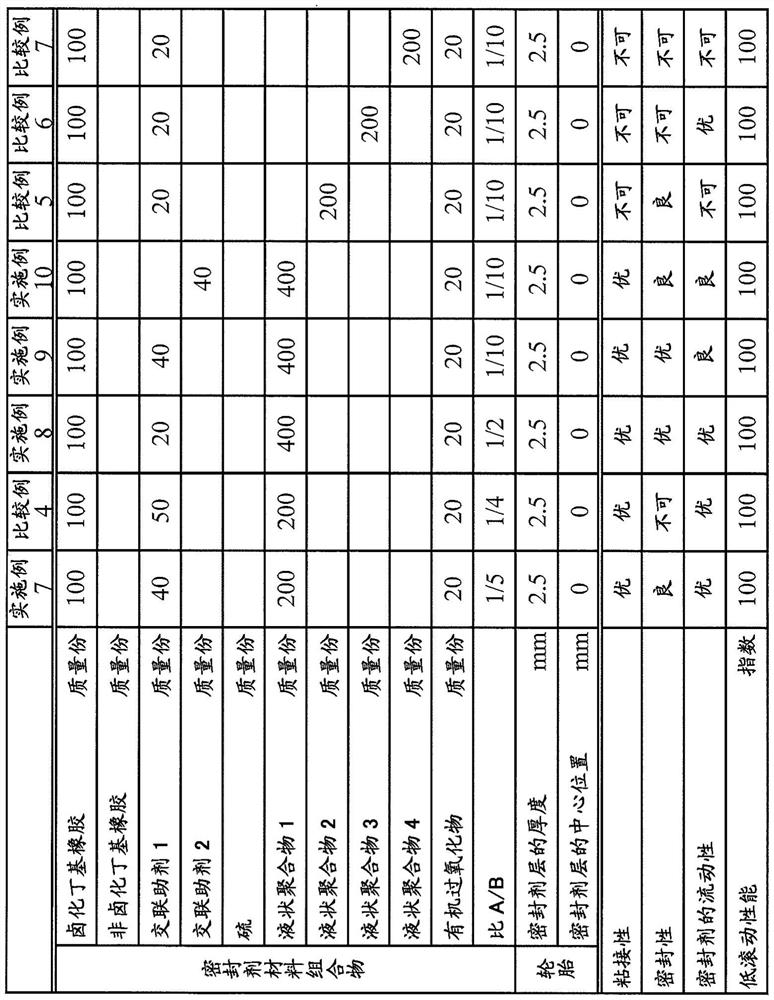

[0042] Made in tire size 215 / 60R16, with figure 1 In the shown basic structure, in a pneumatic tire having a sealant layer on the inside of the inner liner at the tread portion in the tire radial direction, the composition of the sealant material composition constituting the sealant layer, whether or not the inner liner contains a halogenated butyl group The thickness of the rubber, the sealant layer, the distance from the center position of the sealant layer to the tire equator, and the position of the end of the sealant layer were adjusted as shown in Tables 1 to 3 of Comparative Examples 1 to 10 and Examples 1 to 14 tire.

[0043] In addition, in all the examples in Tables 1 to 3, the inner liner was composed of halogenated butyl rubber.

[0044] With regard to these test tires, adhesiveness, sealability, fluidity of the sealant, and low rolling performance were evaluated by the following test methods, and the results are shown in Tables 1 to 3 together.

[0045] Adhesive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com