Sorting equipment for hairbrush processing

A sorting and equipment technology, applied in the direction of brushes, applications, bristles, etc., can solve the problems of huge workload, time-consuming sorting, and poor comparison of brush wire lengths, etc., to achieve the effect of improving sorting efficiency and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

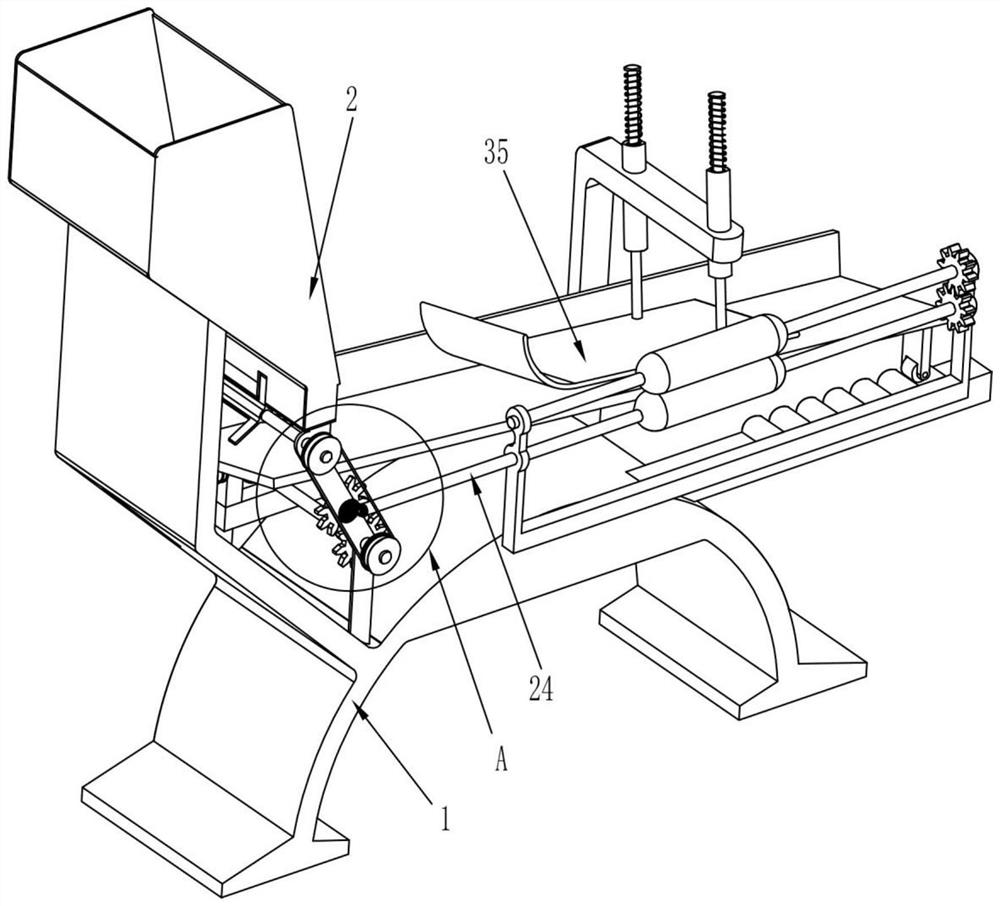

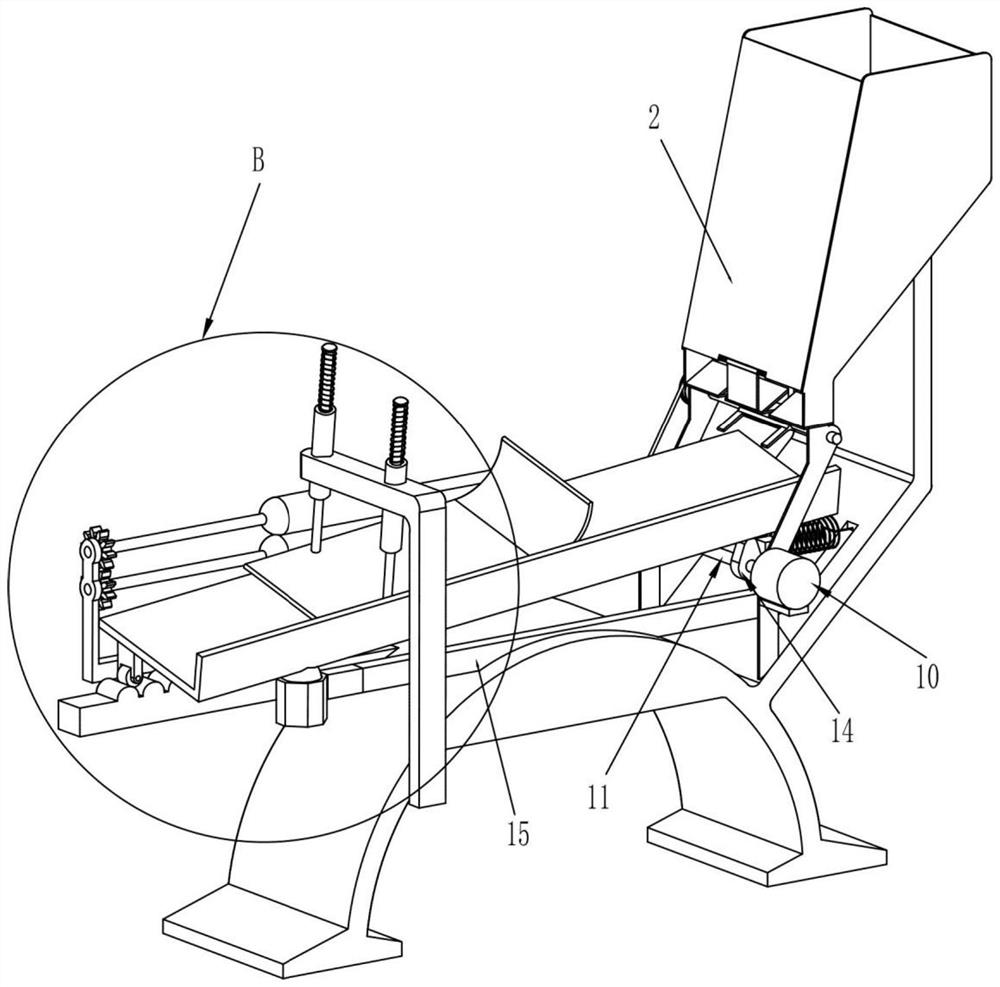

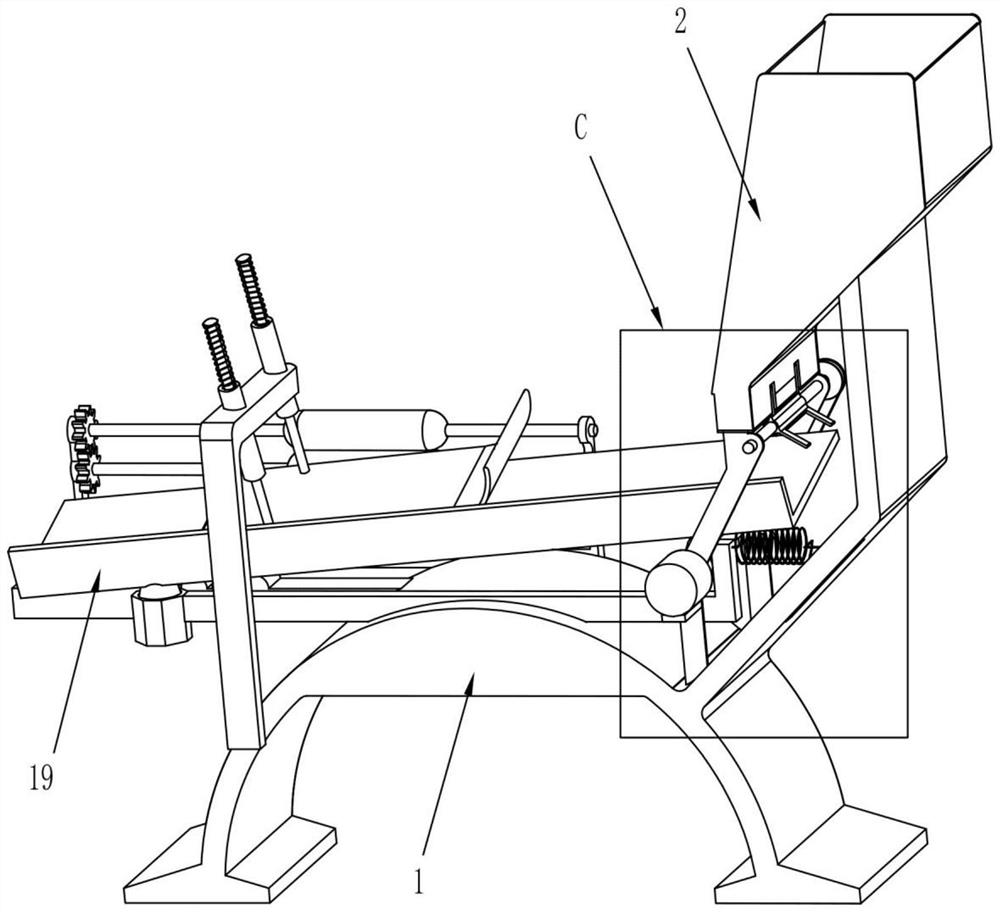

[0024] A sorting device for brush processing, such as Figure 1-8 As shown, it includes a mounting frame-1, a discharge tray 2, a blanking mechanism and a shaking mechanism, and the discharge tray 2 for placing batches of brush filaments is fixedly installed on the mounting frame-1 with a rectangular hole. The unloading mechanism is installed on the mounting frame one 1 and the discharging tray 2 and is located below the discharging tray 2, and the shaking mechanism for shaking is installed on the mounting frame one 1.

[0025] To further illustrate, the unloading mechanism capable of automatically turning the wire brush at the lower port of the unloading tray 2 includes a baffle plate 3, a torsion spring 4, a mounting plate 5, a transmission shaft 6, a feeding turntable 7, a pulley 8, a support Plate 9, drive motor 10, shaft one 11, pulley two 12 and belt 13, the baffle plate 3 that plays a blocking role is rotatably installed on the discharge tray 2 and is positioned at the ...

Embodiment 2

[0029] On the basis of Example 1, such as Figure 1-8As shown, it also includes a transmission mechanism that can automatically sort out longer brush filaments. The transmission mechanism includes mounting plate two 23, roller two 24, transmission gear 25, transmission wheel 26, bevel gear one 27, rotating shaft two 28, cone Gear two 29 and connecting gear 30, described mounting plate two 23 that play a fixed role are fixedly installed on the front side of mounting frame one 1 and are close to convex plate 22, and two described rollers two 24 are rotatably installed on the mounting plate two 23 and Close to the shaking plate 19, the two transmission gears 25 that play a transmission role are fixedly installed on the right ends of the two rollers 24 respectively and mesh with each other, and the two transmission wheels 26 that play a sorting role are fixedly installed on the two rollers 24 respectively. In contact with each other, the bevel gear one 27 is fixedly installed on t...

Embodiment 3

[0032] On the basis of Example 2, such as Figure 1-8 Shown, also comprise the extruding mechanism that can extrude the brush filament so that it can not be piled up in a large amount on the shaking plate 19, extruding mechanism includes mounting frame two 31, guide sleeve 32, guide rod 33, extruding spring 34 and Squeeze the plate 35, the mounting frame 2 31 that plays a fixing role is fixedly installed on the rear side of the mounting frame 1 and close to the shaking plate 19, and the two guide sleeves 32 are fixedly mounted on the mounting frame 2 31 and arranged symmetrically , the two guide rods 33 are slidably installed in the two guide sleeves 32 respectively, the lower ends of the two squeeze springs 34 are respectively fixedly connected with the upper ends of the guide sleeves 32, and the upper ends are fixedly connected with the bumps on the guide rods 33, and the guide rods 33 passes through the extruding spring 34, and the extruding plate 35 having the extruding ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com