A device for separating damaged waste metal products for classification of medical waste

A technology for metal products and medical waste, applied in the field of separation devices for damaging waste metal products for medical waste classification, can solve the problems of low manual separation efficiency, workers are easily cut and infected, and achieve the effect of reducing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

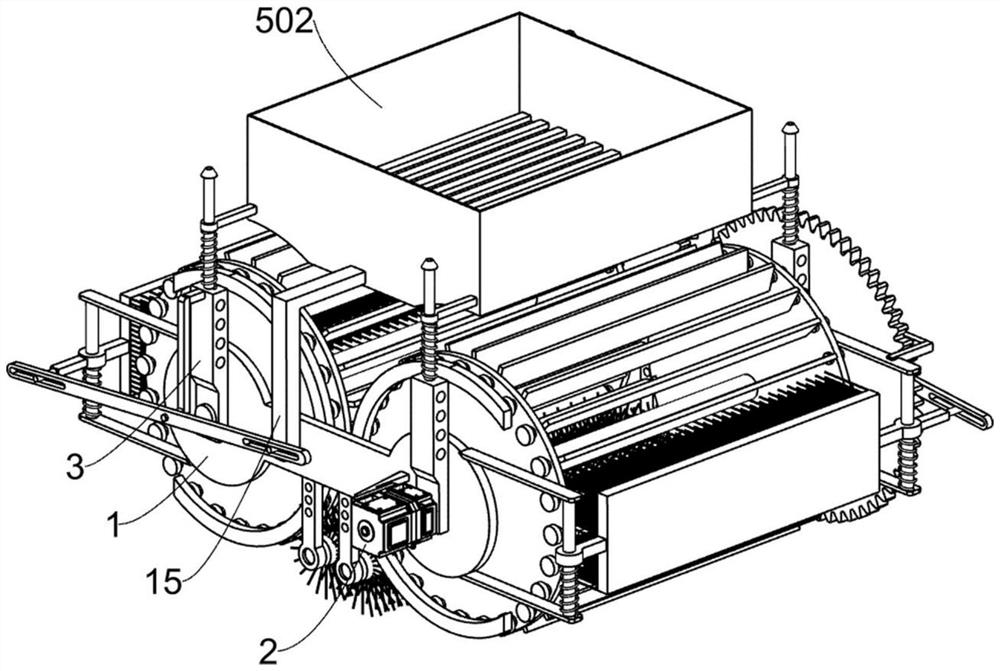

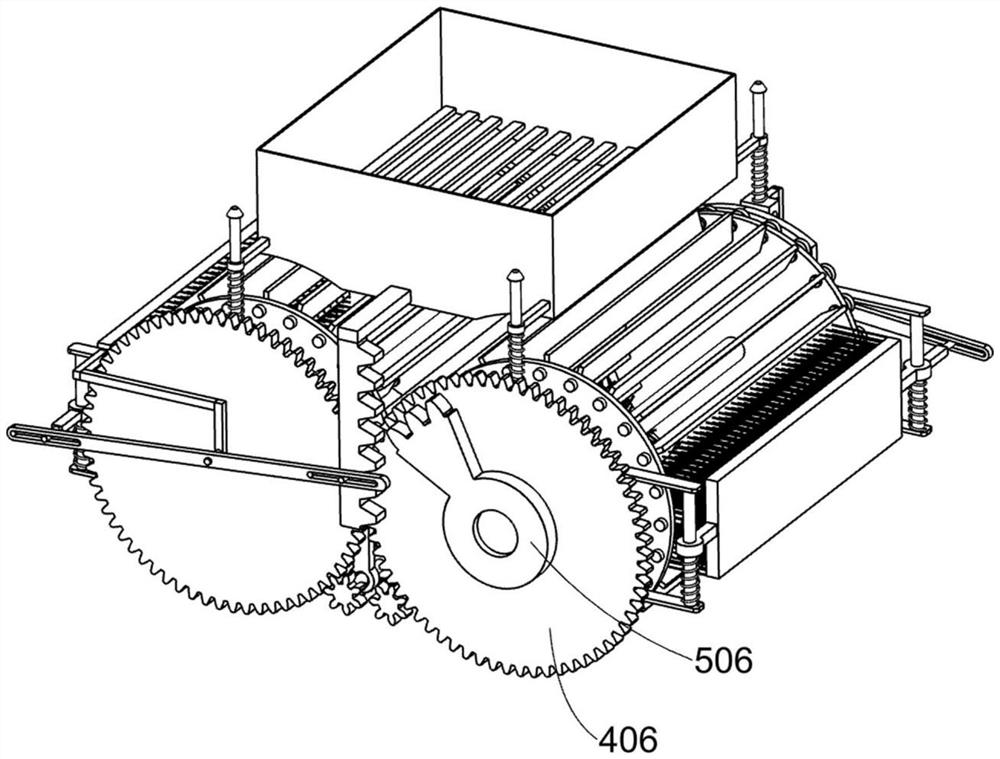

[0022] A device for separating damaged metal products for medical waste classification, such as Figure 1-7 As shown, it includes a mounting plate 1, a servo motor 2, a guide support column 3, a metal product adsorption and separation mechanism 4, a damaged waste batch shake-off mechanism 5 and a glass slag scraping mechanism 6, and the servo motor 2 is fixed therein. A side surface of a mounting plate 1, two symmetrical guide support columns 3 are fixed on the two mounting plates 1, and one of the guide support columns 3 is close to the servo motor 2, which is used for adsorbing metal medical waste. The metal product adsorption and separation mechanism 4 is arranged on the two mounting plates 1, the damaged waste batch shake-off mechanism 5 is arranged on the guide support column 3, and the glass slag scraping mechanism 6 is arranged on the two mounting plates 1 and is connected to the two mounting plates 1. The metal product adsorption and separation mechanism 4 is connected...

specific Embodiment approach 2

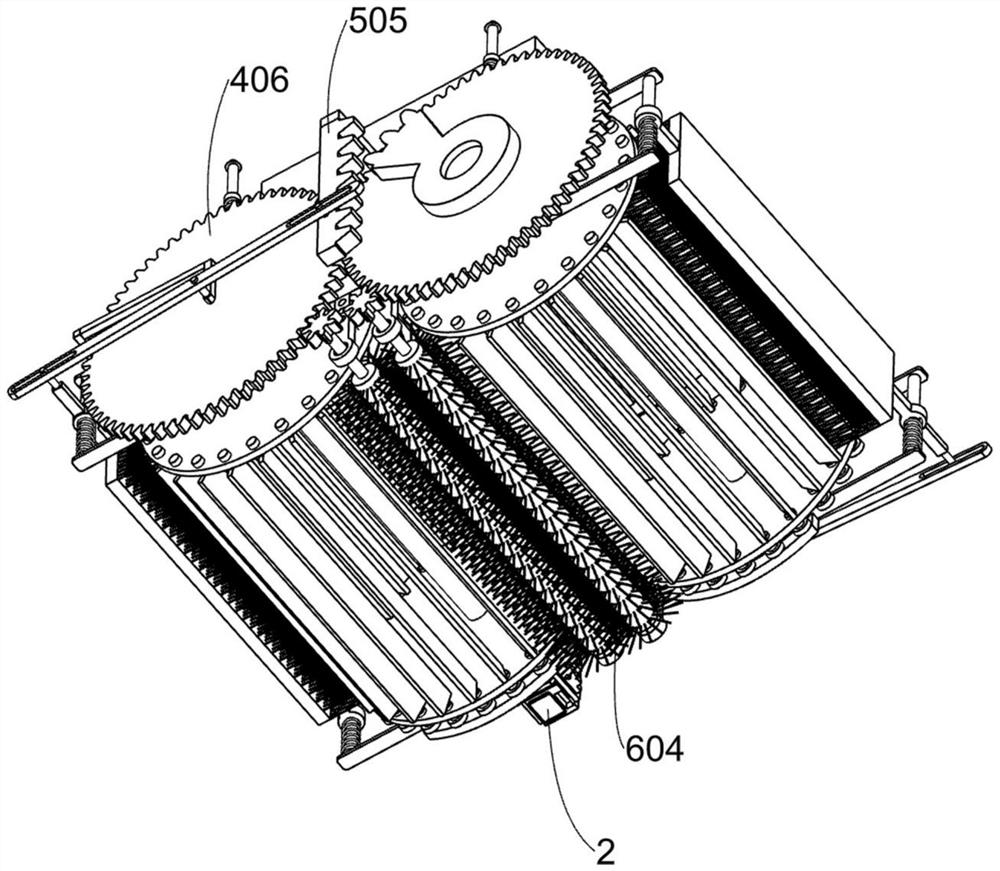

[0027] On the basis of Embodiment 1, as image 3 and Image 6 As shown, the glass slag scraping mechanism 6 for scraping off the glass fragments of the clips on the electromagnet plate 403 includes a mounting bar 601, a second driving shaft 602, a small diameter driving gear 603 and a brush roller 604 for scraping off hair. Two parallel mounting bars 601 are fixed on the mounting plate 1 , the lower ends of the two sets of mounting bars 601 are provided with a second drive shaft 602 through a bearing, and one end of the two second drive shafts 602 is fixed with a small diameter The driving gear 603 and the two small-diameter driving gears 603 are meshed with the two large-diameter driving gears 406 respectively. Both the second driving shafts 602 are fixedly provided with scraping brush rollers for scraping off the glass fragments on the electromagnet plate 403 604 and the two scraping brush rollers 604 are in contact with the electromagnet plate 403, the two small diameter d...

specific Embodiment approach 3

[0029] On the basis of the second embodiment, as Figure 7 As shown, it also includes a guide frame 7, a movable bar 8, a scraping brush plate 9, a second compression spring 10, a push rod 11, a support frame 12, a swing groove rod 13, a bar 14 and an L-shaped frame 15. Both ends of the mounting plate 1 are fixedly provided with guide frames 7 , the movable bars 8 are slidably arranged on the guide frames 7 , and a scraping brush plate 9 is fixed between the two sets of movable bars 8 . The scraping brush plate 9 is in contact with the electromagnet plate 403, and the two scraping brush plates 9 are used to scrape off the metal garbage on the electromagnet plate 403 in time. A second compression spring 10 is arranged between and the guide frame 7 passes through the second compression spring 10. The support frame 12 is fixed on one of the guide frames 7, and both the support frame 12 and one of the guide support columns 3 rotate. There is a swinging slot rod 13 and both ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com